sliding reamer

A technology of reaming and spiral bands, which is applied in the field of design and manufacture of reamers used in oil fields, can solve the problems of drill sticking, single usage, inflexibility and convenience, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

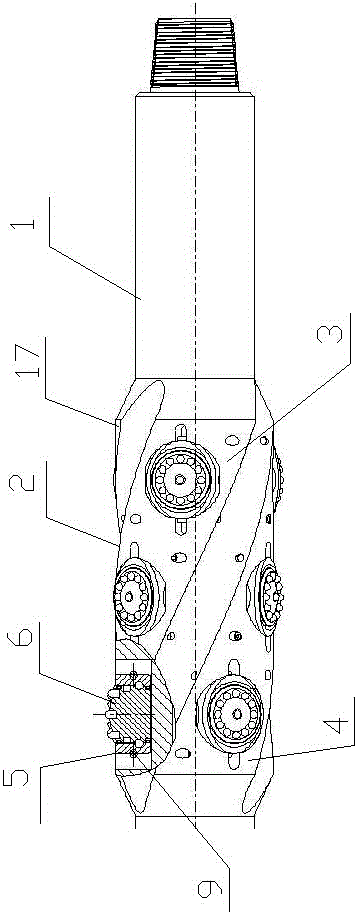

[0026] Such as figure 1 , 3 Shown, the present invention comprises drill string body 1, is provided with reaming section 2 on drill string body 1, and reaming section 2 is the cylinder structure that diameter increases; Band 3, the second spiral band 4, the third spiral band 17; the starting point of the first spiral band 3 and the stop point of the second spiral band 4 are on the same plane passing the axis; in the first spiral band 3, the second The working surfaces of the spiral belt 4 and the third spiral belt 17 are respectively provided with wheel body installation grooves 5; in each wheel body installation groove 5, a cone assembly 6 is respectively detachably arranged.

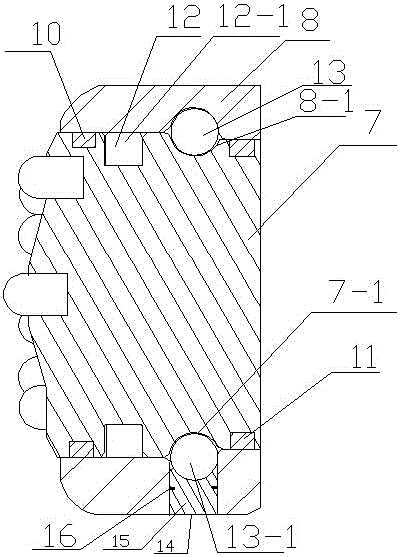

[0027] Each cone assembly 6 includes a cone 7 and a fixed sleeve 8; the fixed sleeve 8 is connected to the wheel body installation groove 5 through a threaded pin 9; a first "U"-shaped seal is provided between the cone 7 and the fixed sleeve 8 Ring 10, second "U"-shaped sealing ring 11, roller group ...

Embodiment 2

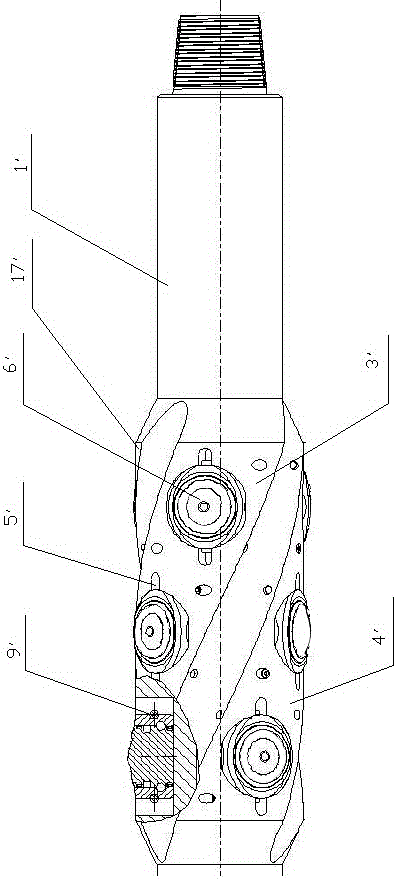

[0033] Such as figure 2 , 4 Shown, the present invention comprises drill string body 1 ', is provided with reaming section 2 ' on drill string main body 1 ', and described reaming section 2 ' is the cylinder structure that diameter increases; The first helical band 3', the second helical band 4', and the third helical band 17' are arranged on the outer peripheral surface; On the plane; wheel body installation grooves 5' are respectively set on the working surfaces of the first spiral belt 3', the second spiral belt 4' and the third spiral belt 17'; each wheel body installation groove 5' is detachable Set up the centralizing wheel assembly 6'.

[0034] Each righting wheel assembly 6' includes a righting wheel 7' and a fixed sleeve 8' respectively; the fixed sleeve 8' is connected to the wheel body installation groove 5' through a threaded pin 9'; Set the first "U"-shaped sealing ring 10', the second "U"-shaped sealing ring 11', the roller set 12', the steel ball set 13'; fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com