Reamer belt construction with reaming function

A technology of reamer and belt, which is applied in the field of reamer, can solve the problems such as low reaming efficiency of reamer, low connection stability, inconvenient welding operation, etc., and achieves improved reaming efficiency, simple structure, improved The effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

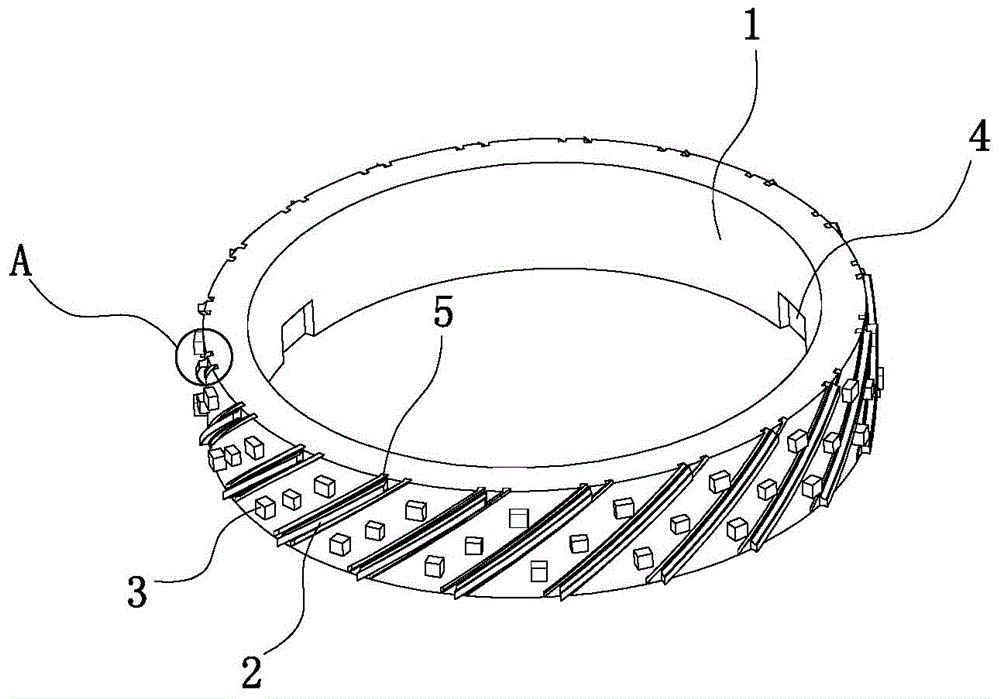

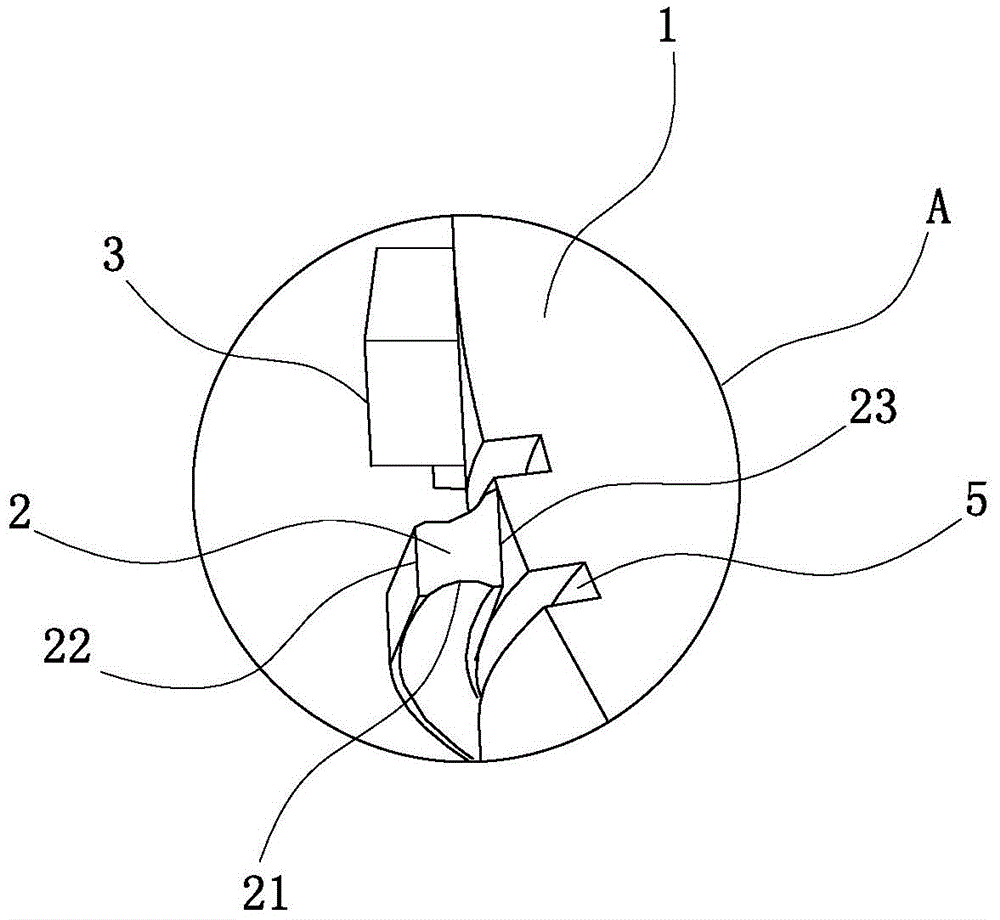

[0016] like figure 1 , figure 2 As shown, the reamer belt structure with the reaming function of the present embodiment includes a belt 1 of annular structure, and the inner wall of the belt is symmetrically provided with a plurality of welding grooves 4, and the welding groove 4 is a square groove structure, which is beneficial to The square connecting rod is welded to it; the outer wall of the belt 1 is provided with a plurality of reaming bars 2, and the reaming bars 2 are arranged obliquely relative to the central axis of the belt 1, and the belt 1 on both sides of the reaming bar 2 has a The water guide groove 5 is provided, and an alloy block group is arranged between adjacent reaming bars 2 , and the alloy block group includes a plurality of alloy blocks 3 arranged along the reaming bars 2 .

[0017] The cross-section of the ream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com