Drill-free fast fixing structure for led light source

A technology of LED light source and fixed structure, applied in the direction of light source fixation, light source, electric light source, etc., can solve the problems of mismatch between drilling and screw holes, complicated installation, inability to install, etc., to achieve convenient splicing and position adjustment, and improve tolerance Fault tolerance, the effect of reducing installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

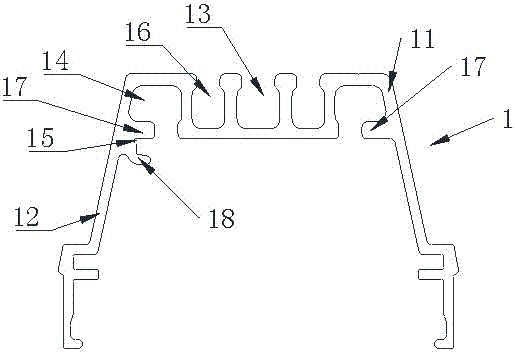

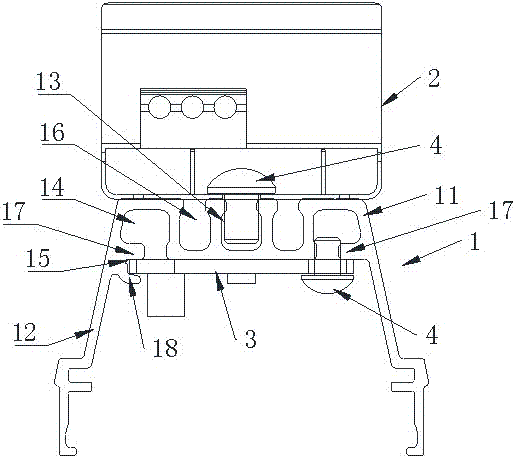

[0022] Such as figure 1 As shown, the fast fixing structure of the LED light source without drilling in this embodiment includes a housing 1, a driving power supply 2 is provided on the back of the housing 1, and an LED substrate 3 is provided inside the housing 1. The housing 1 It includes a component mounting part 11 and side shell parts 12 extending obliquely downward from both sides of the component mounting part 11. The component mounting part 11 and the side shell parts 12 extend in a strip shape. The surface is provided with one or more driving power fixing grooves 13 inwardly recessed, and the driving power fixing grooves 13 extend along the extension direction of the component mounting part 11, and the driving power 2 is fixed to the driving power fixing grooves 13 by fasteners 4 Middle; the lower surface of the component mounting part 11 is provided with an LED substrate fixing groove 14, and a card slot 15 is provided on the inner wall of the side shell part 12 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com