Bearing contact angle measuring instrument

A measuring instrument and contact angle technology, which is applied in the field of bearings, can solve the problems of easily damaged bearings under test, large measurement errors, and affecting measurement accuracy, and achieve the effect of measuring the size of the contact angle, small environmental influence factors, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with the accompanying drawings, the preferred embodiments of the present invention are described in detail as follows:

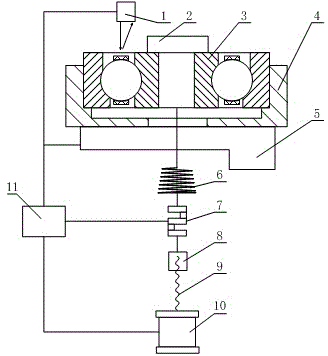

[0031] like figure 1 As shown in the figure, a bearing contact angle measuring instrument is mainly composed of a loading mechanism, a positioning driving mechanism, and a measurement control part; The servo motor 10 is connected with the lead screw 9, the lead screw 9 and the nut 8 form a lead screw nut drive, a tension sensor 7 is installed above the nut 8, and the spring 6 is installed between the tension sensor 7 and the load rod 2; the positioning drive The mechanism is composed of a hollow rotating platform 5 and a main shaft 4. The tested bearing 3 is installed in the holder of the main shaft 4, the load rod 2 is pressed on the inner ring of the tested bearing 3, and the inner ring of the tested bearing 3 is fixed, and the main shaft 4 is installed in the hollow. On the rotating platform 5; the measurement control part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com