Offline automobile gearbox NVH (noise, vibration and harshness) detecting method

A technology of automobile gearbox and detection method, which is applied in the direction of measuring device, machine gear/transmission mechanism test, measurement of ultrasonic/sonic wave/infrasonic wave, etc., which can solve the problem of abnormal operation of gearbox, difficulty in fault vibration, and difficulty in quantitatively evaluating the operating state of gearbox And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The implementation examples of the present invention are described in detail, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

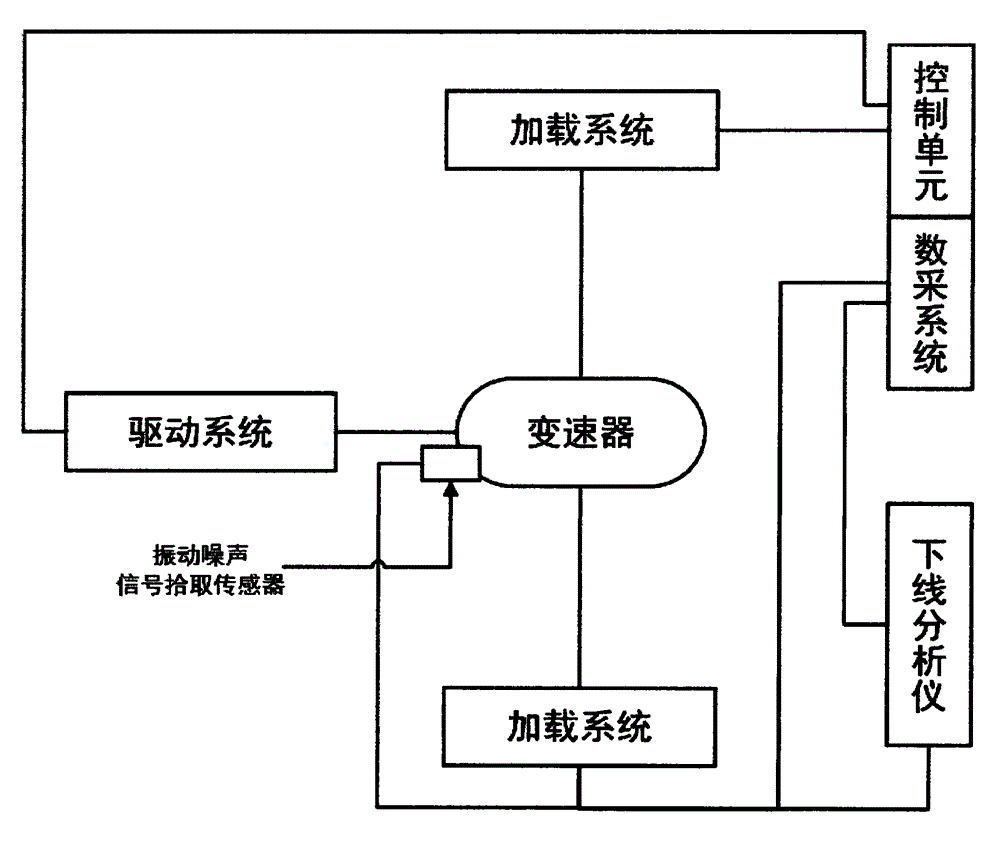

[0013] See attached figure 1 , an off-line detection method for NVH of an automobile gearbox, comprising an off-line analyzer, a control unit, a data acquisition system, a loading system, a drive system, and a gearbox, and a vibration and noise pickup sensor is installed in the gearbox.

[0014] The working principle of the invention is detailed below:

[0015] The gearbox to be tested enters the testing station through an automatic assembly line, and the vibration and noise pickup sensor automatically contacts the gearbox case. The off-line analyzer sends instructions to the control unit according to the preset test sequence, and the data acquisition system collects the parameters involved in the gearbox ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com