Marine thrust bearing equipment test apparatus

A thrust bearing and test device technology, which is applied in the direction of mechanical bearing testing, etc., can solve problems such as inability to completely simulate the flow of lubricating oil in thrust bearing equipment, failure to meet product batch test requirements, long time-consuming shaft alignment and installation, etc., to save The effect of installation man-hours, low requirements on shaft alignment, and strong compensation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

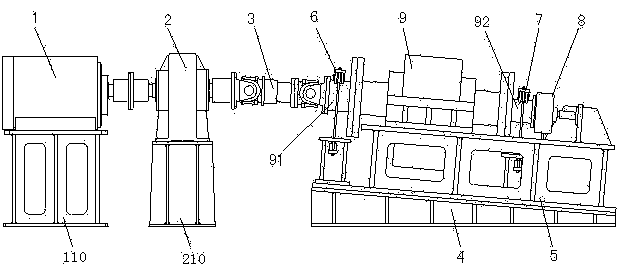

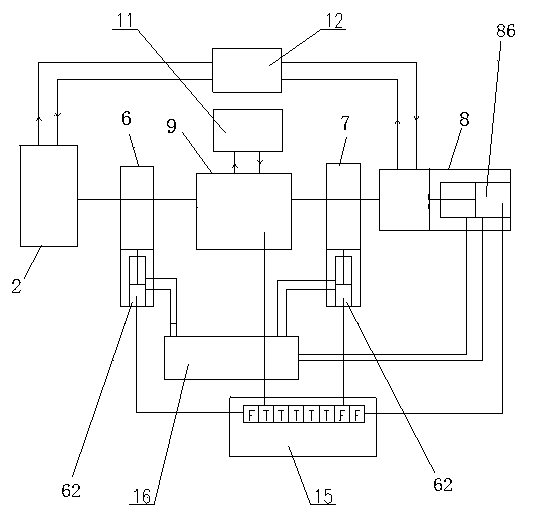

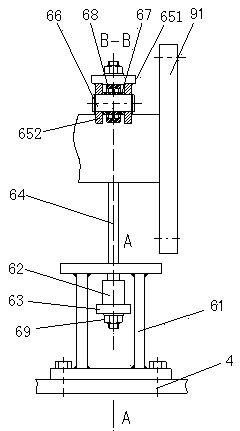

[0017] See figure 1 with figure 2 . The marine thrust bearing equipment test device according to an embodiment of the present invention is used to simulate the axial thrust of the propeller and the state of both ends bearing the shafting load when the thrust bearing equipment is in operation on a real ship, and the performance of the thrust bearing equipment 9 is tested. Test; it includes variable frequency speed regulating motor 1, gearbox 2, universal coupling 3, inclined base 4, equipment stand 5, input end radial loading device 6, output end radial loading device 7, axial loading device 8. Cooling device 11, lubricating pump station 12, data monitoring device 15 and hydraulic control device 16. As shown in the figure, 110 is a variable frequency speed regulating motor base, and 210 is a gear box base.

[0018] The variable frequency speed regulating motor 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com