Rotating detonation engine experimental device

An experimental device and engine technology, applied in the field of engine research, can solve the problems of non-adjustable, low quality of fuel and oxygen mixing, unreasonable placement of sensors, etc., and achieve the effect of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

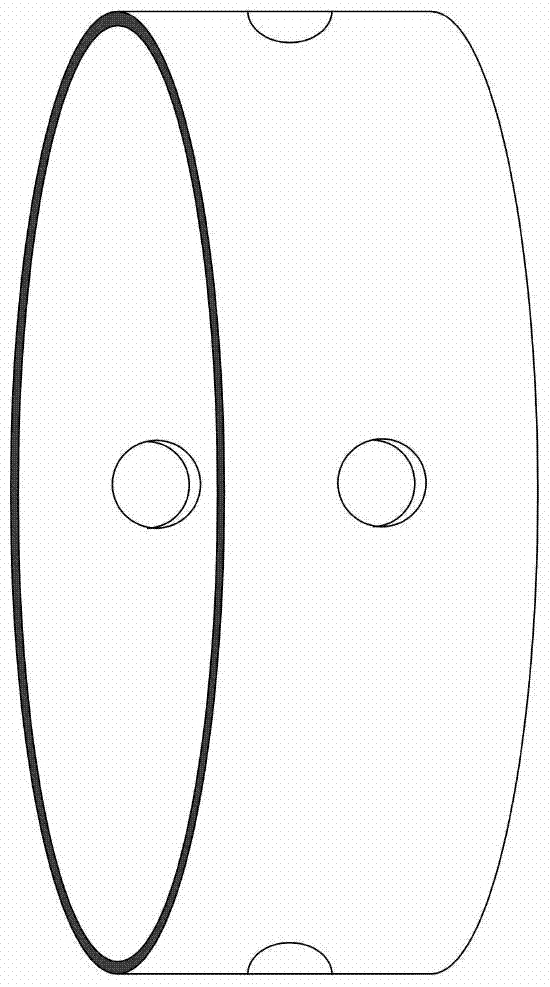

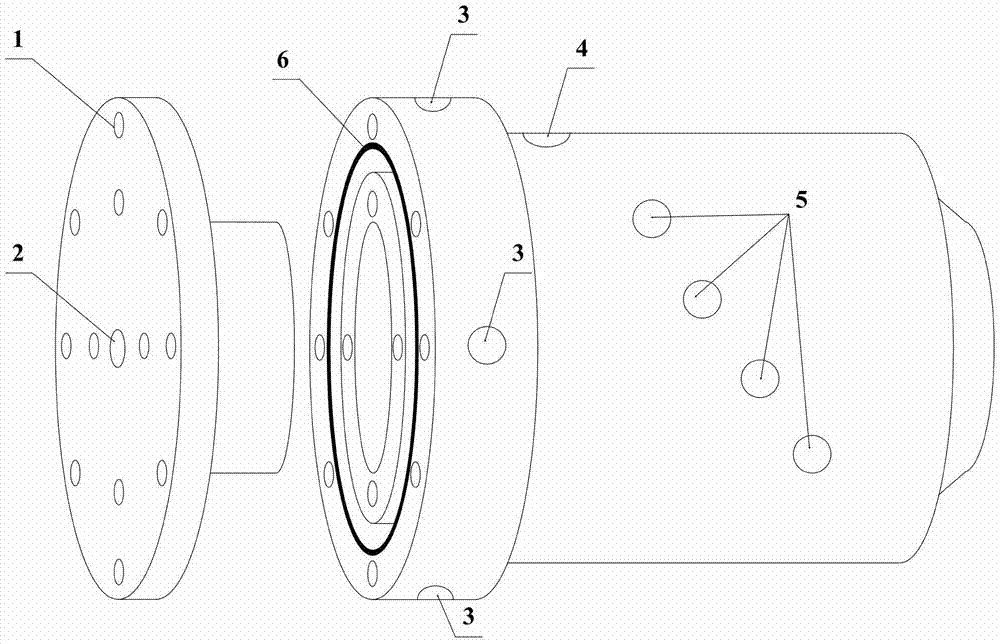

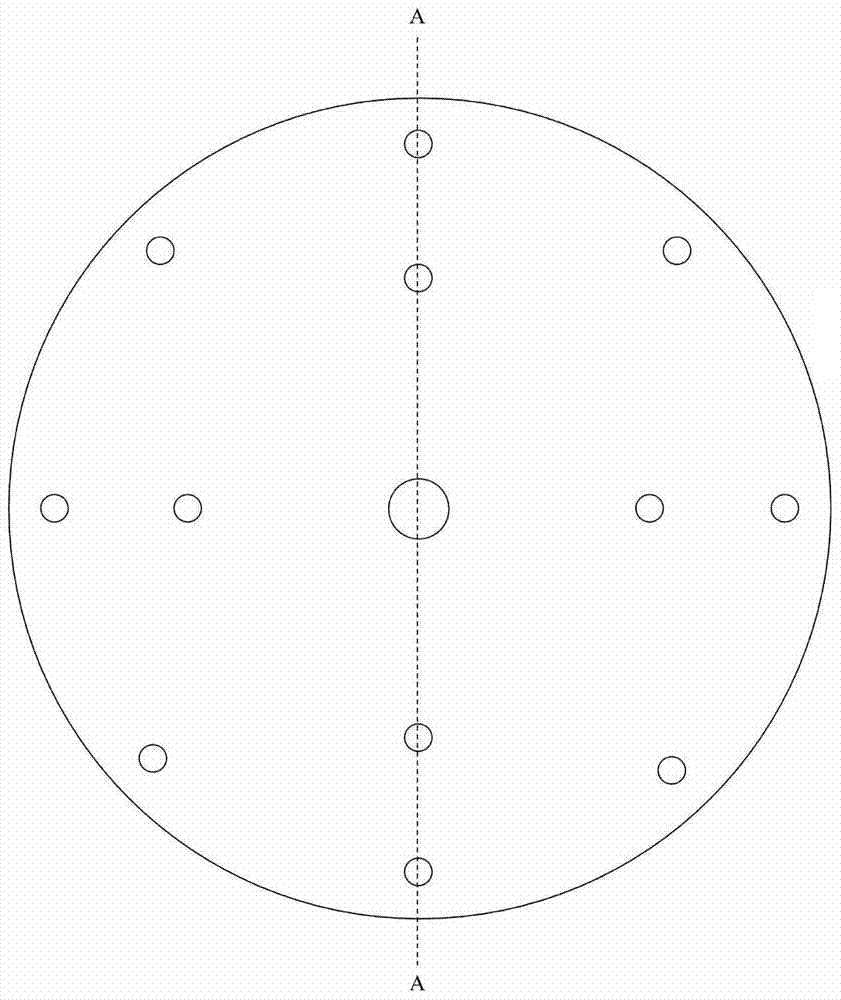

[0031] Rotary detonation engine experimental device, including end cover, outer wall, inner cavity and fuel input control ring 6; screw holes 1, oxygen input port 2 are distributed on the end cover; screw holes 1, fuel input port 3 are distributed on the outer wall, ignition Placement port 4, sensor placement port 5; screw holes 1 are distributed on the inner cavity, oxygen is at the entrance 7 of the annular combustion chamber, and fuel is at the entrance 8 of the annular combustion chamber; through holes are distributed on the fuel input control ring;

[0032] Connection relationship:

[0033] The end cover is a cylindrical body with steps, and there are screw holes 1 and oxygen input port 2 distributed on the end cover;

[0034] The outer wall is a hollow cylinder, with a boss on the outside of the bottom end of the cylinder, and a groove on the inside of the bottom end; the outer wall is distributed with screw holes 1, fuel input port 3, igniter placement port 4, sensor pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com