Bolt and cable pull-out strength tester

An anchor cable puller and bolt technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of short reserve, lack of test conditions, and inability to perform bolt and anchor cable test detection. , to ensure the quality of the project and prevent cutting corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

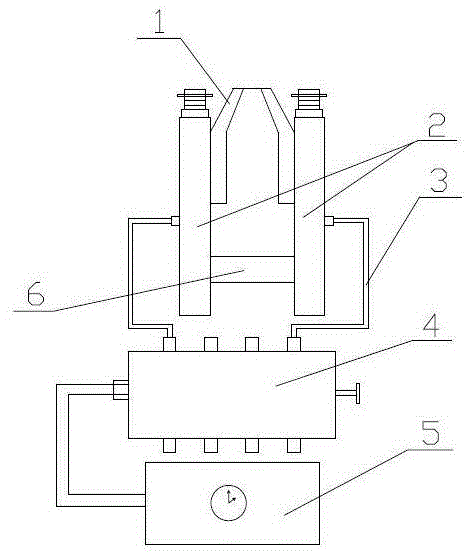

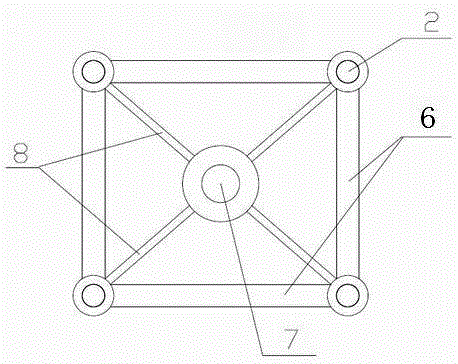

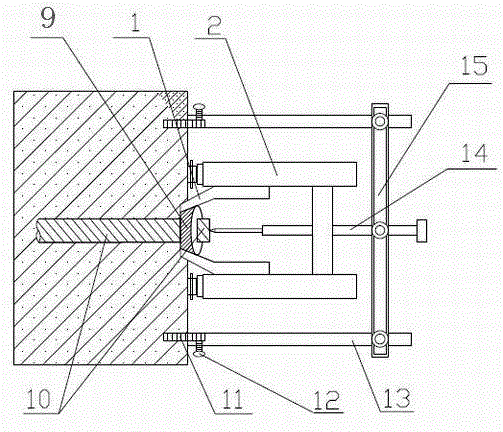

[0011] An anchor rod and anchor cable pulling instrument, including a conical anchor 1, a clip 9, a jack, an oil delivery pipe 3, a hydraulic distribution valve 4, an oil pressure pump 5, a horizontal support 13, a positioning frame 15, and a displacement meter 14. That is, the jacks with screw-type adjusting top plates are evenly arranged, and are connected into one body with the connecting plate 6 to form the synchronous jack 2. The conical anchor 1 is fixed on the front end of the synchronous jack 2 through the anchor connecting plate 8, and protrudes beyond the The adjustment top plate and the jack are all connected to the hydraulic pump 5 through the oil delivery pipe 3 and the hydraulic distribution valve 4; the horizontal brackets 13 are connected by a positioning frame 15, the displacement meter 14 is installed in the middle of the positioning frame 15, and the horizontal bracket 13 is connected by a fixing screw 12 It is connected with the expansion screw 11 installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com