Carrier, thin film transistor array substrate manufacturing method and liquid crystal display panel manufacturing method

A technology of thin film transistors and array substrates, which is applied in the field of liquid crystal displays, can solve the problems of reducing the production yield of thin film transistor array substrates and liquid crystal panels, deformation, and warping of ultra-thin glass substrates, so as to achieve difficult support, protect the environment, and improve production The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

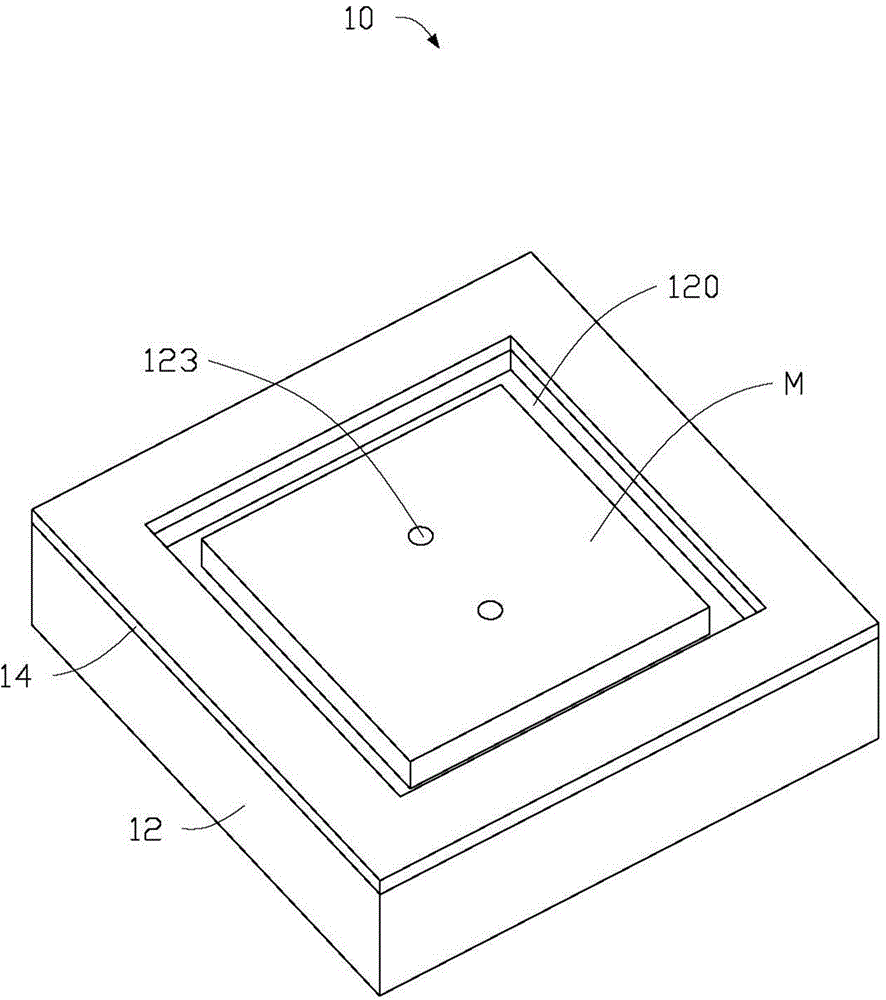

[0017] see figure 1 , is the carrier 10 provided in the first embodiment of the present invention. The carrier 10 includes a body 12 and an adhesive layer 14 .

[0018] Please combine figure 2 , the body 12 has a rectangular structure and includes a top surface 122 and a bottom surface 124 . The top surface 122 and the bottom surface 124 are respectively located on opposite sides of the main body 12 , and the top surface 122 is parallel to the bottom surface 124 . The top surface 122 defines a closed first groove 120 in the shape of a rectangular ring, and the first groove 120 does not penetrate through the bottom surface 124 . The area surrounded by the first groove 120 is defined as the active area M. The main body 12 defines a plurality of ventilation holes 123 passing through the top surface 122 and the bottom surface 124 , and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com