A built-in oil-immersed transformer nitrogen injection device

An oil-immersed transformer, built-in technology, used in transformer/inductor parts, electrical components, fire rescue and other directions, can solve the problems of hidden fire accidents, long distance from the fault point, increased oil pressure, etc., and achieve the effect of nitrogen injection Good, easy installation, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

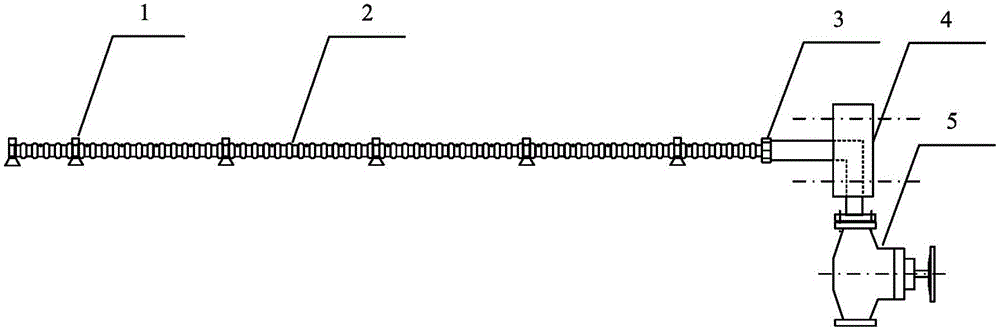

[0020] Such as figure 1 , Figure 5 As shown, a built-in oil-immersed transformer nitrogen injection device includes: a nitrogen inlet pipe, a fixing device for the nitrogen inlet pipe, a connecting flange 4 and a stop valve 5 . The nitrogen inlet pipe adopts perforated corrugated pipe 2, and the fixing device of nitrogen inlet pipe adopts permanent magnet 1. The perforated corrugated pipe 2 is arranged at the bottom of the transformer oil tank 8 and fixed by permanent magnet 1. The hole on the perforated corrugated pipe 2 faces the transformer The winding 10 and one end of the perforated bellows 2 are connected to the connecting flange 4 through the connecting nut 3 .

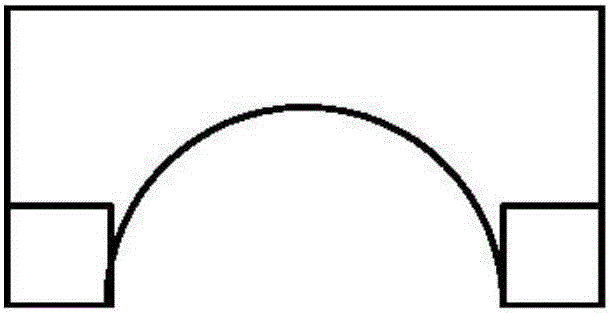

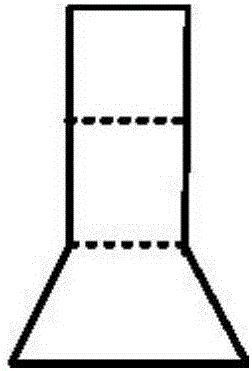

[0021] Such as Figure 4 , Figure 5 As shown, the connecting flange 4 is provided with a front and rear channel 11 and a middle channel 12, and the connecting flange 4 is installed between the oil discharge port 6 and the oil discharge valve 7 of the transformer oil tank through bolts, and the front and re...

Embodiment 2

[0025] This embodiment focuses on the differences from the previous embodiments, and the similarities will not be repeated. The difference between this embodiment and the previous embodiments is that the perforated bellows 2 can be arranged on the inner wall of the transformer oil tank 8, and the perforated bellows The holes on the 2 face the transformer winding 10, and are fixed by the permanent magnet 1. This example makes use of the flexible characteristics of bellows, which is suitable for transformer oil tank walls of various shapes such as round, square, and hexagonal, and the nitrogen injection hole is close to the middle of the winding, which is prone to failure, and has the advantages of short nitrogen injection distance and fast cooling speed. Fast, timely, effective and other advantages.

Embodiment 3

[0027] This embodiment focuses on the differences from the previous embodiments, and the similarities will not be repeated. The difference between this embodiment and the previous embodiments is that multiple perforated corrugated pipes 2 can be arranged on the bottom or four walls of the transformer oil tank 8 On the top, preferably, there are 2 on the bottom and 2 on the four walls, and they are connected to the connecting flange 4 through a five-way joint. This example improves the speed of nitrogen injection, and has the advantages of fast cooling speed, wide range and good effect.

[0028] The middle channel 12 of the connecting flange 4 in the above embodiments can be used as an oil intake port and an oil chromatography monitoring port, and only a three-way connecting piece needs to be inserted between the connecting flange 4 and the shut-off valve 5 .

[0029] As the front-end device of the nitrogen injection system, the present invention can be connected with other aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com