Filter cake blowing apparatus of filter press

A technology of blowing device and filter press, which is applied in the direction of filtration separation, separation method, chemical instrument and method, etc. It can solve the problems of the influence of filtration efficiency, reduce the recovery rate of filtrate, and the purity of filter cake, etc., and achieve simple structure , improve filtration efficiency, increase the effect of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

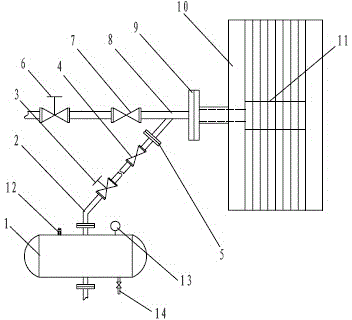

[0012] see figure 1 As shown, the present invention provides a filter cake blowing device for a filter press, the device welds a feed flange 9 and a pipeline to connect a filter plate feed hole 11 to a filter press thrust plate 10, and the feed flange 9 connects the feed The flange of the pipeline 8 is fastened with bolts. The material used for the feed pipeline 8 is seamless steel pipe. The feed pipeline 8 is equipped with a check valve 7 and a feed control valve 6 to connect the feed pump. The opening of the feed pipeline 8 is welded and blown Pipeline 2, welded blowing pipe 2 is provided with a slope of 30 degrees to 45 degrees, so that the blowing air can quickly enter the chamber. The material used in blowing pipe 2 is seamless steel pipe. The blowing pipe 2 is equipped with one-way valve 4 and blowing control valve 3 connection, the blowing pipe 2 is provided with a connecting flange 5 and fastened with bolts, and an air storage tank 1 is provided. The air storage tank i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com