Grinding disc for waste rubber smashing device

A crushing device and waste rubber technology, which is applied in the field of rubber mechanical components, can solve the problems of inability to maintain plane characteristics for a long time, high energy consumption, and difficult repair, etc., and achieve the effect of simple structure, large crushing area, and low unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

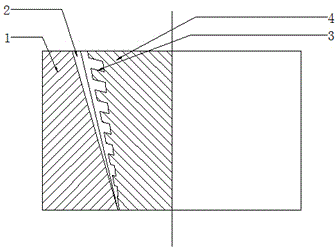

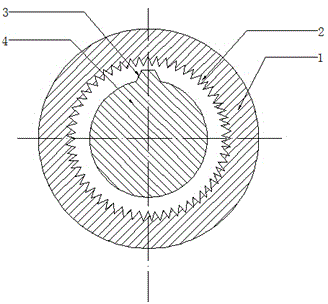

[0017] see figure 1 , figure 2 , the present invention is made up of movable grinding disc and fixed grinding disc. 1 is a fixed grinding disc, 2 is a triangular tooth of a fixed grinding disc, 3 is a moving grinding disc thread, and 4 is a moving grinding disc.

[0018] The feeding device generates a driving force on the rubber material, and continuously pushes the rubber material into the gap between the grinding discs. The rubber material first enters the area with a large gap from the large end; Crushing, reducing the size of the rubber material; then entering the area with small gaps, the area adopts narrower alveolar and shallow teeth, and further pulverizes the rubber material to achieve a satisfactory crushing effect.

[0019] The size of the cone angle of the movable grinding table has a great influence on the energy consumption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com