Tension control method for continuous processing line with large specification range and capacity

A tension control and wire processing technology, applied in the field of strip steel production, can solve the problems of inability to meet the requirements of process accuracy, large fluctuations in strip tension and speed, unstable working conditions, etc., and achieve ideal control effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

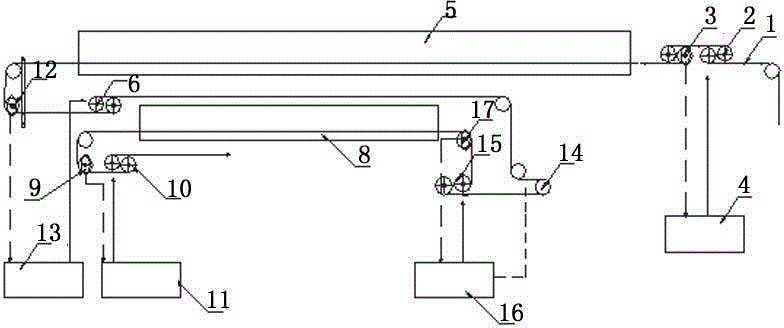

[0013] Such as Figure 4 As shown, in the traditional control mode, the first tension roller group 2 measures the actual value of the entrance tension of the heat treatment furnace through the first tension meter 3, and the first tension roller group 2 is adjusted in real time through the first tension closed-loop control unit 4 to realize heat treatment. Stability of furnace 5 inlet tension. The second tension roller group 6 is for speed control to keep the speed of the process section stable. The fourth tension roller group 10 measures the actual value of the outlet tension of the pickling section 8 through the fourth tensiometer 9, and adjusts the fourth tension roller group 10 in real time through the fourth tension closed-loop control unit to realize the stability of the outlet tension of the pickling section.

[0014] In recent years, the production of metallurgical strips in the world, especially stainless steel strips, has developed rapidly. In order to increase produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com