Starfish groove type multi-station conversion device

A transformation device, starfish groove technology, applied in positioning devices, clamping devices, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive efficiency of roof beam formwork, hidden dangers of safety accidents, and retrogression when turning over, so as to achieve convenient and fast operation. The effect of preventing backsliding or slipping and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

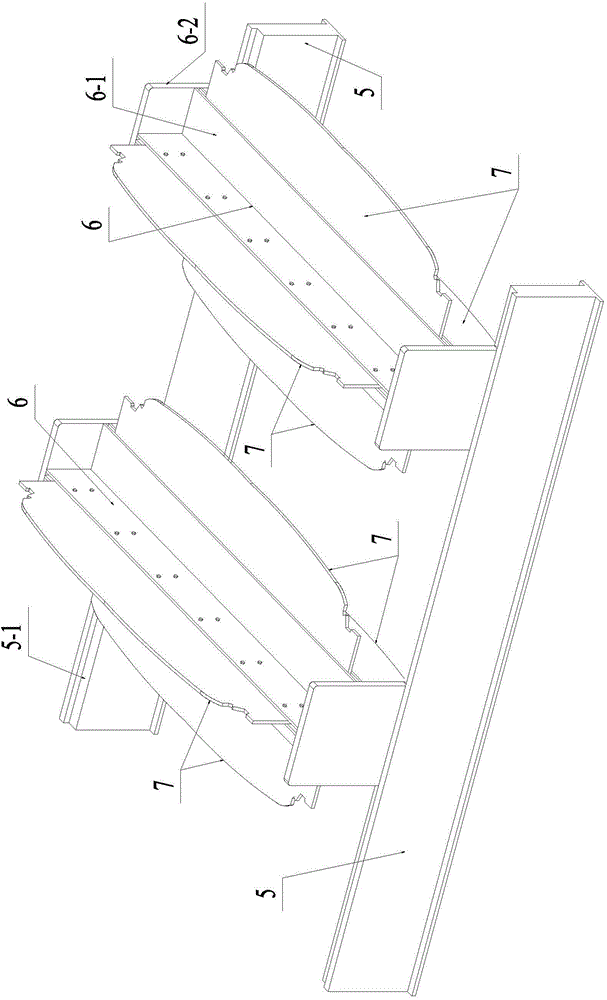

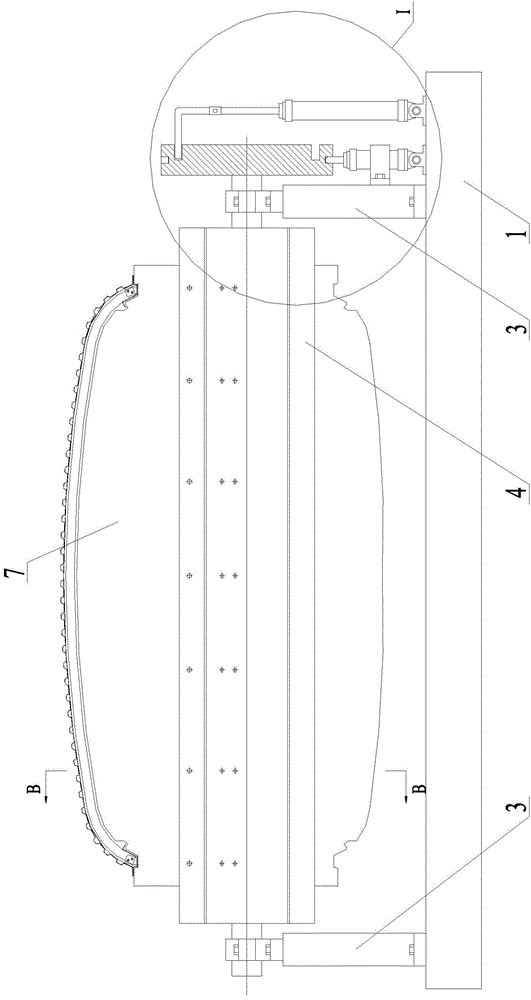

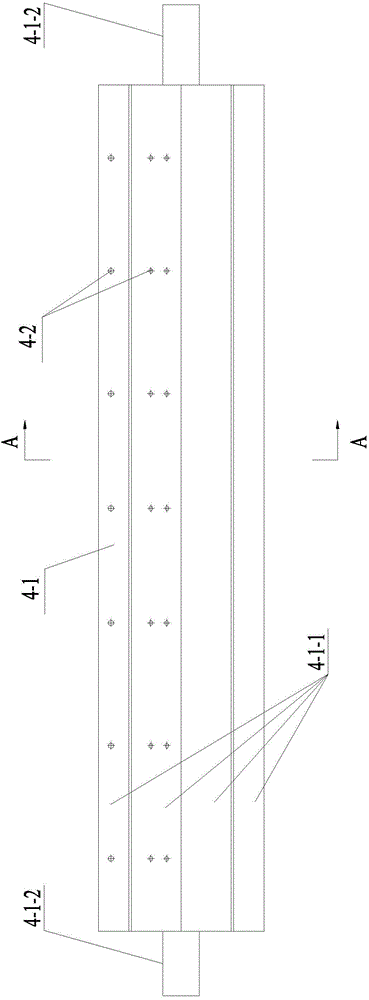

[0024] Such as Figure 2 to Figure 8 As shown, the starfish trough type multi-station conversion device of the present invention includes a base platform 1, an intermittent turning mechanism 2, a template turning fixture 4 for positioning the roof beam and two axle seats 3, and the template turning fixture 4 includes a plurality of bolts 4-2 and a clamp assembly 4-1, the clamp assembly 4-1 includes a plurality of splints 4-1-1 with through grooves and two rotating shafts 4-1-2, a plurality of splints with pass grooves 4-1- 1 integrally formed and spaced apart from each other at a circumferential angle of 60 degrees; both ends of multiple splints 4-1-1 with through grooves are coaxially connected with a rotating shaft 4-1-2; splints with through grooves 4-1 A side wall of -1 is provided with a plurality of screw holes; two shaft seats 3 are fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com