Powdery dyestuff feeding device with rotary-dialing mechanical arm

A feeding device and powdery dye technology, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve the problems of polluting the working environment, scattered dyes, and low material accuracy, so as to reduce pollution, liberate labor, Avoid the effects of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

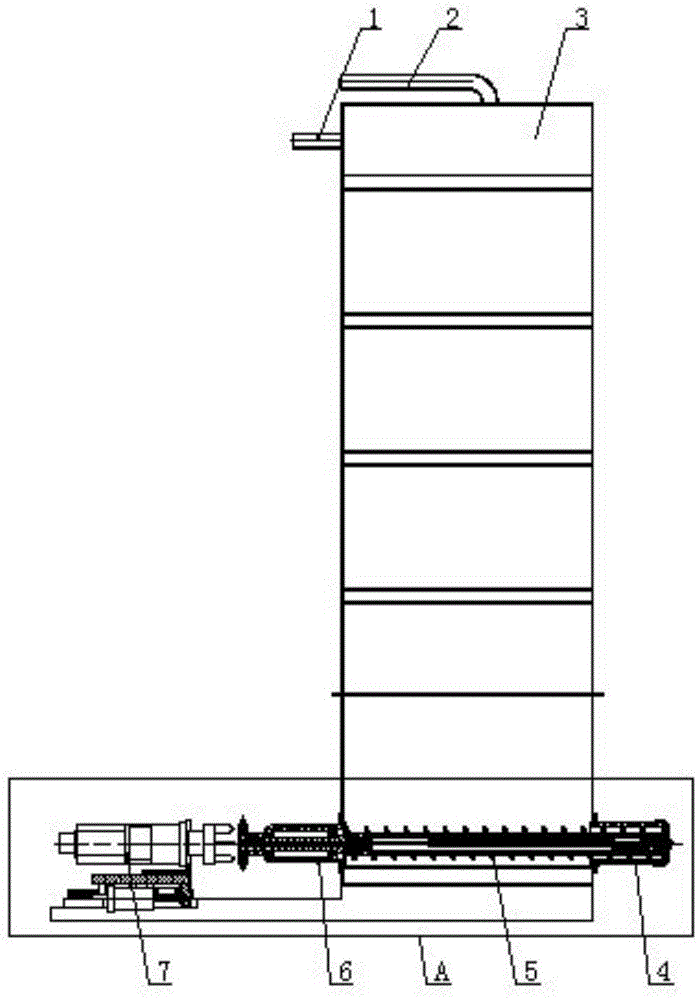

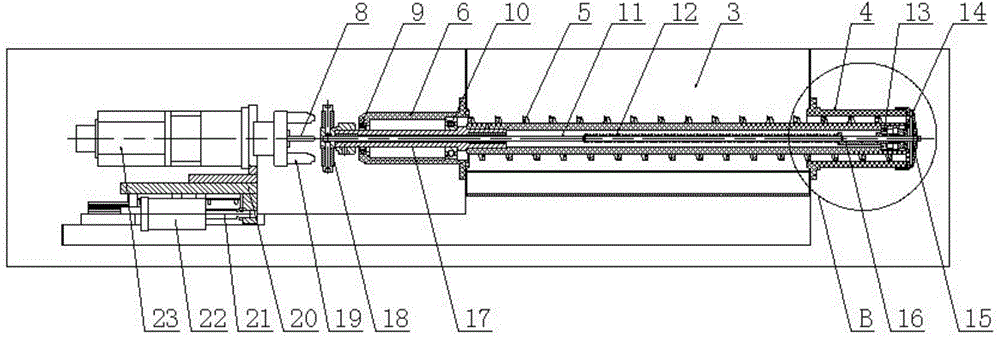

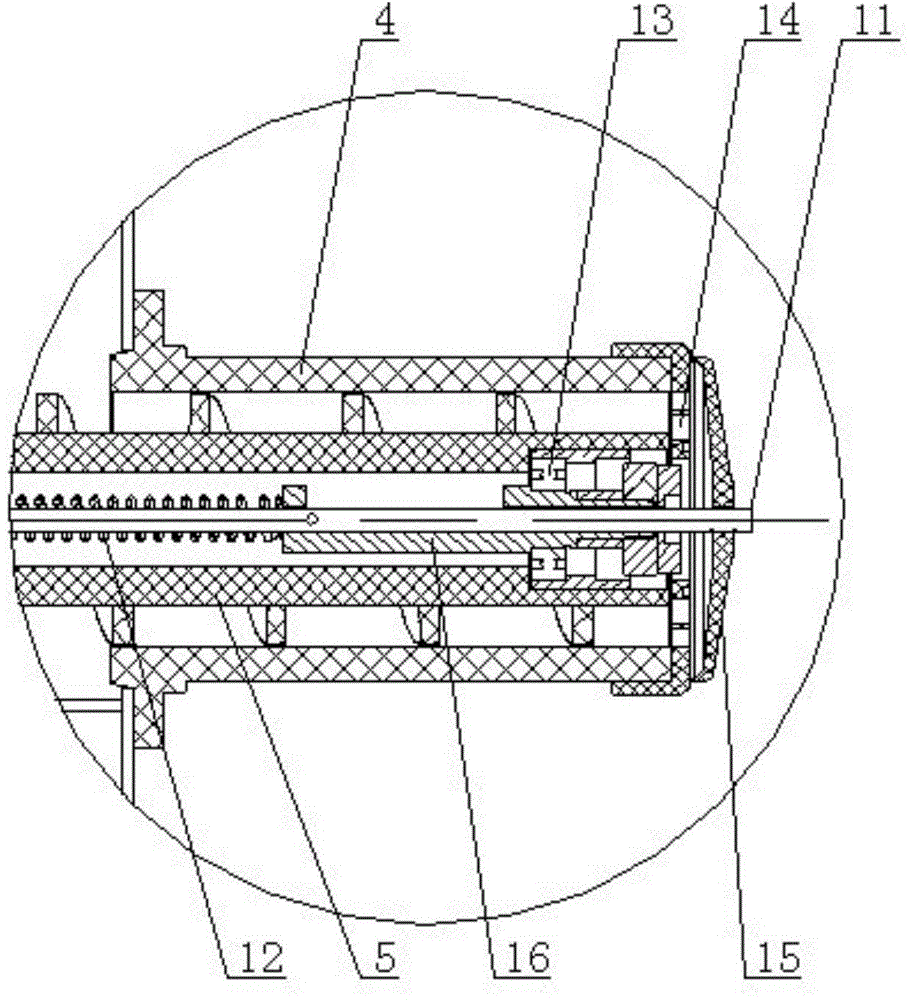

[0022] A powdery dye feeding device with a rotary manipulator, the device includes a dye box 3, a screw conveying rod 5, a feeding front end cover 4, a feeding rear end cover 6 and a rotary manipulator 7, the rotary manipulator includes a dial Catch 19, motor 23 and cylinder 22, turn and grab and be installed on the rotating shaft of motor, motor is installed on the push rod 21 of cylinder, further say that motor is installed on the push rod of cylinder by motor mount 20, dye box upper end system Out of the feeding port 1 and the negative pressure tuyere 2, the feeding front cover is fixed on one side of the dye box, the feeding rear end cover is fixed on the corresponding other side, and the screw conveying rod is set in the dye box and rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com