Diamagnetic plastic composite material and preparation method thereof

A composite material and magnetic material technology, applied in the field of diamagnetic plastic composite material and its preparation, can solve problems such as damage to magnetism, and achieve the effects of low cost, simple process, and excellent diamagnetic and antistatic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Correspondingly, an embodiment of the present invention provides a method for preparing the above diamagnetic plastic composite material, including the following steps:

[0029] S01, weigh each component according to the above antimagnetic plastic composite material formula;

[0030] S02, the above-mentioned plastics, compatibilizer, lubricant, and modified NdFeB are mixed and extruded to obtain a mixed material;

[0031] S03, mixing the above-mentioned mixed material with the magnetic material and antioxidant, and melt extruding to obtain the above-mentioned diamagnetic plastic composite material.

[0032] Specifically, in the above step S01, use an electronic scale (with an accuracy of 1.0%) to weigh the above-mentioned components of the above-mentioned diamagnetic plastic composite material in proportion. .

[0033] Specifically, in the above step S02, the plastic, compatibilizer, lubricant, and modified NdFeB weighed in step S01 are added to a high-speed mixer and...

Embodiment 1

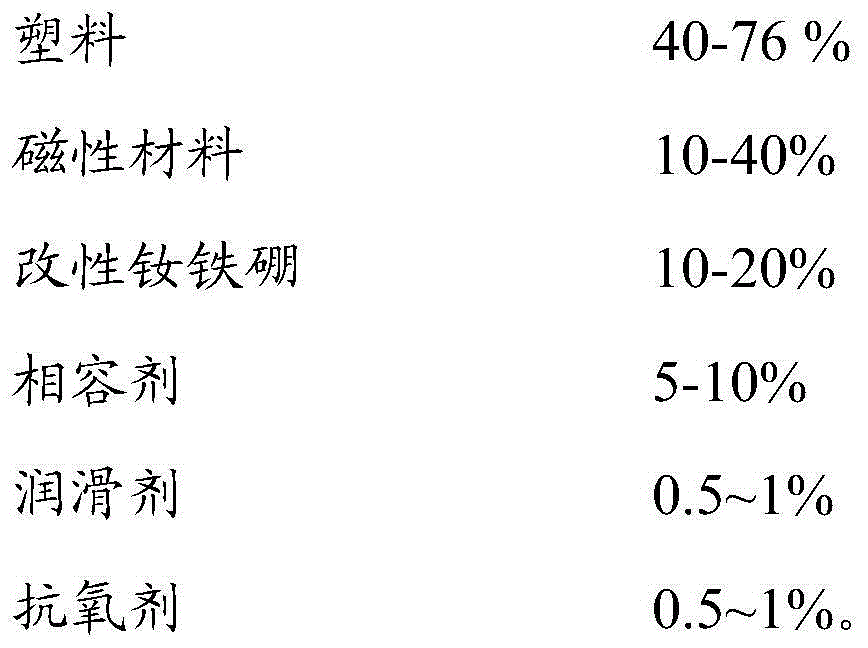

[0040] A kind of antimagnetic plastic composite material, comprises the formula component of following percentage by weight:

[0041]

[0042] The preparation method of the antimagnetic plastic composite material comprises the following steps:

[0043] S11, weighing the formula components: weighing each component according to the above antimagnetic plastic composite material formula;

[0044] S12, preparing the mixed material: adding the plastics, compatibilizer, lubricant, and modified NdFeB weighed in step S11 into a high-speed mixer and mixing evenly, then placing the mixture in a twin-screw machine, and melt extruding to obtain Mixed material; wherein, the temperature of the melt extrusion is 110-170°C, the pressure is 10-20Mpa, and the time is 1-2 minutes;

[0045] S13, obtaining anti-magnetic plastic composite material: adding the mixed material obtained in step S12, the above-mentioned magnetic material and antioxidant into a high-speed mixer and mixing evenly, then...

Embodiment 2

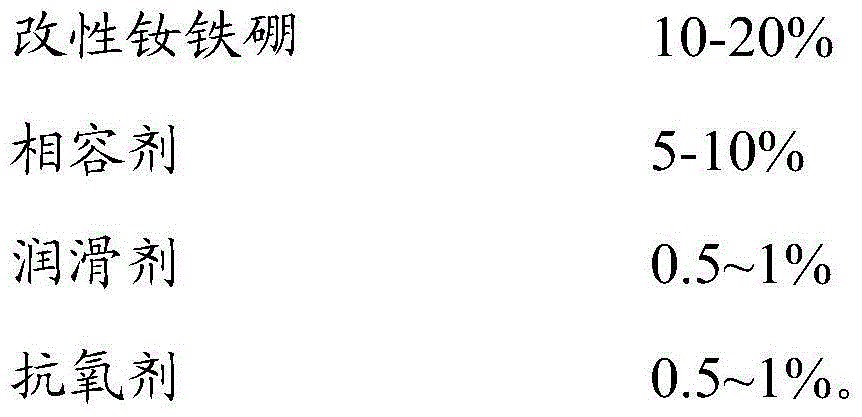

[0047] A kind of antimagnetic plastic composite material, comprises the formula component of following percentage by weight:

[0048]

[0049] The preparation method of this diamagnetic plastic composite material is as follows:

[0050] S21, weighing the formula components: weighing each component according to the above antimagnetic plastic composite material formula;

[0051]S22, preparing the mixed material: sequentially add the plastics, compatibilizer, lubricant, and modified NdFeB weighed in step S21 into a high-speed mixer and mix evenly, then place the mixture in a twin-screw machine, and melt and extrude it. Obtain a mixed material; wherein, the temperature of the melt extrusion is 110-170°C, the pressure is 10-20Mpa, and the time is 1-2 minutes;

[0052] S23, obtain antimagnetic plastic composite material: add the mixed material obtained in step S22, the above-mentioned magnetic material and antioxidant into a high-speed mixer and mix evenly, then place it in a tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com