Unidirectional flow guidance type blast apparatus

A technology of blasting equipment and unidirectional flow, applied in the direction of leather drying, etc., can solve the problems of low drying efficiency, long drying time, long time consumption, etc., and achieve the effect of improving utilization rate, avoiding convection and ensuring sufficient contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

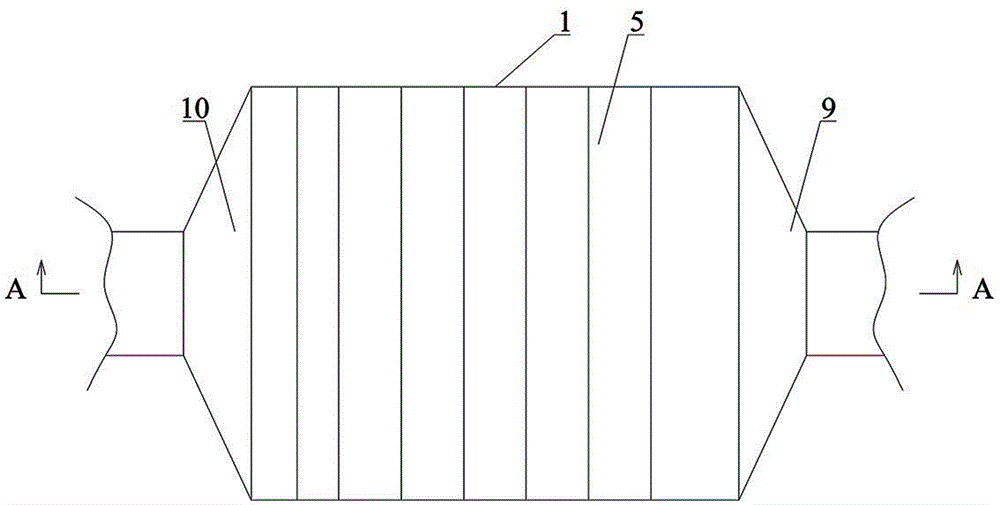

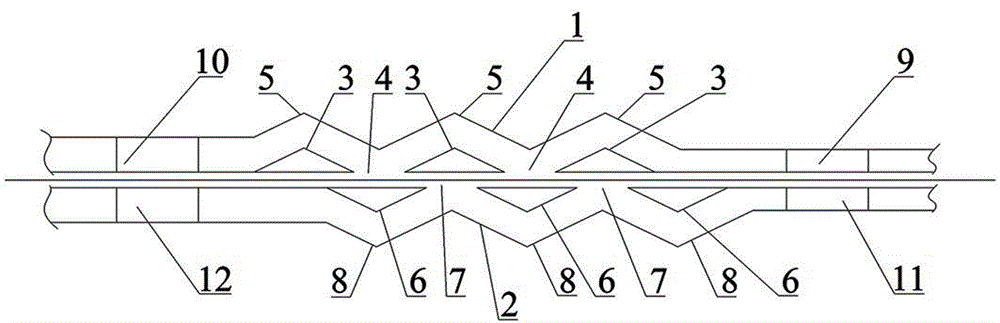

[0018] Such as figure 1 , figure 2 As shown, a kind of unidirectional flow blowing equipment, comprises the upper blowing pipe 1 that is arranged on the upper part of the leather to be dried and the lower blowing pipe 2 that is arranged on the lower part of the leather to be dried, and the leather to be dried is driven by the conveying device, Between the upper blast pipe 1 and the lower blast pipe 2, it is transmitted to the right in the horizontal direction. The right ends of the upper blast pipe 1 and the lower blast pipe 2 are provided with air inlets communicating with their respective internal spaces. The upper blast pipe 1 and the left end of the lower blast pipe 2 are all provided with air outlets communicating with their respective interior spaces. The width of the upper blast pipe 1 and the lower blast pipe 2 in the front and rear direction is not less than the width of the leather to be dried in the front and rear direction. The bottom surface of the air duct 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com