Node system for laminated wood space structure

A space structure, glued wood technology, applied in the direction of building structure, construction, etc., can solve the problems of cracking and damage of glued wood transverse grain, difficult to guarantee the strength of planting reinforcement, and occupying scaffolding for a long time, so as to save construction cost and transmit force at nodes The path is simple and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

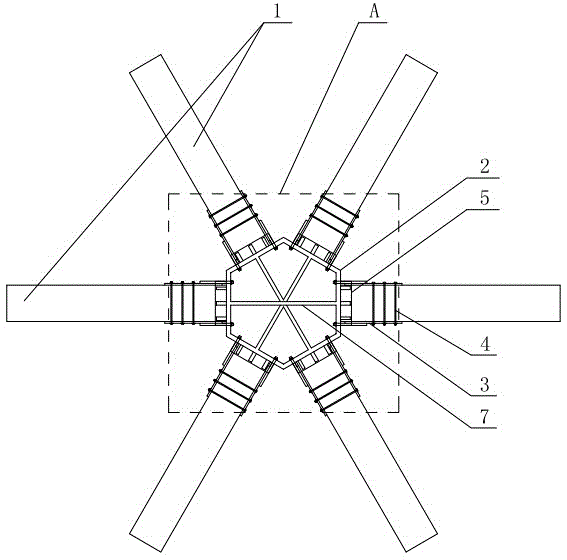

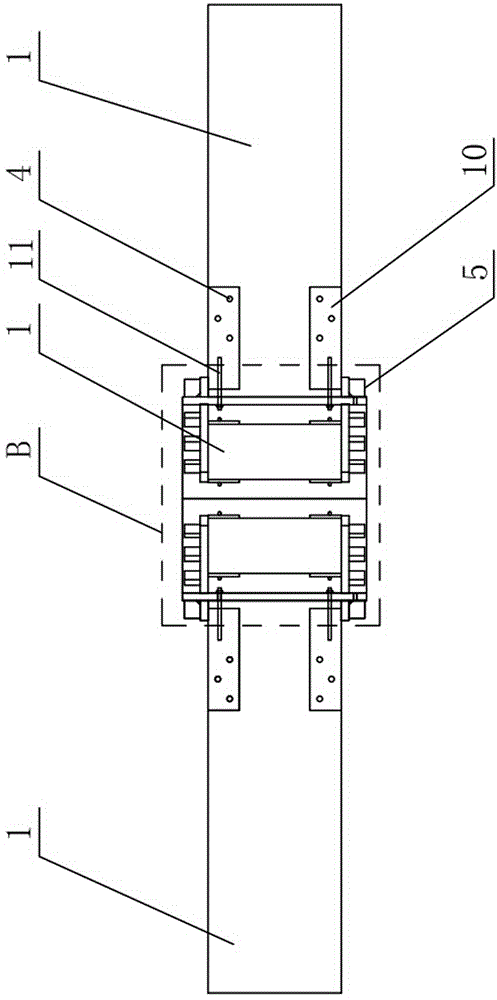

[0022] Specific implementation mode one: as Figure 1~Figure 3 , Figure 7 and Figure 8 As shown, a node system for glulam space structure, which includes a plurality of glulam components 1; said node system for glulam space structure also includes node steel hub 2, multiple groups of bolt plates and multiple Bolt 4; the outer surface of the node steel hub 2 is detachably connected to multiple groups of bolt plates, each group of bolt plates includes four bolt plates 3, and the four bolt plates 3 of each group of bolt plates are detachably connected There is a glulam member 1 .

specific Embodiment approach 2

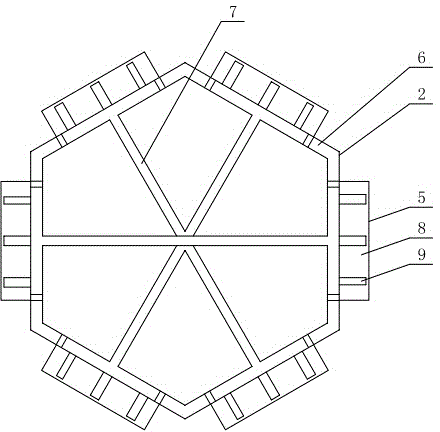

[0023] Specific implementation mode two: as Figure 1~Figure 3 , Figure 5 , Figure 7 and Figure 8 As shown, a node system for glued wood space structure described in the first embodiment, the node steel hub 2 is composed of a polygonal steel frame 6, a plurality of stiffeners 7 and a plurality of support members 5; A stiffener 7 is welded between every two opposite inner sides of the polygonal steel frame 6 (playing the role of strengthening the polygonal steel frame 6), and each outer side of the polygonal steel frame 6 is welded with two The supporting parts 5, the two supporting parts 5 are set up and down facing each other (for supporting the glued wood member 1), and each outer surface of the polygonal steel frame 6 is detachably connected with a group of bolt plates, and The group of bolt plates is located between the two supporting parts 5 , and the distance between the two supporting parts 5 facing up and down is equal to the height of the section of the glued wo...

specific Embodiment approach 3

[0024] Specific implementation mode three: as Figure 1~Figure 3 and Figure 5~Figure 8 As shown, in the joint system for glued wood space structure described in the second embodiment, the plurality of support members 5 are all composed of steel plate one 8 and multiple stiffeners two 9; the steel plate one The outer surface of 8 is welded with a plurality of stiffeners 2 9, and the steel plate 8 and the plurality of stiffeners 2 9 are welded to the outer surface of the polygonal steel frame 6. The effect of this embodiment is that the overall strength and rigidity of the node steel hub 2 can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com