Novel partial pressure injection tool

A partial pressure and tool technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problem of high viscosity loss, achieve small viscosity loss, reduce shear damage, and reduce viscosity loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described further below:

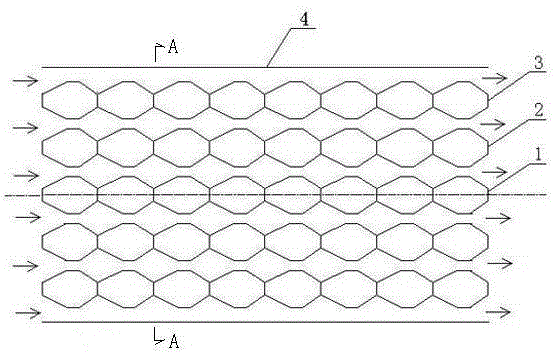

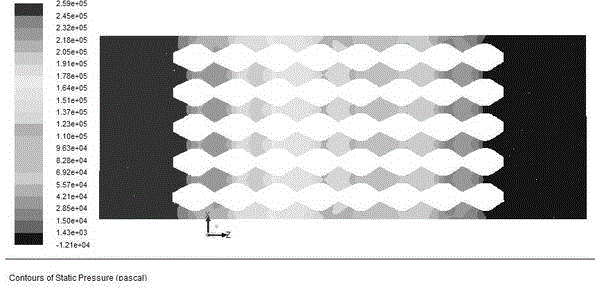

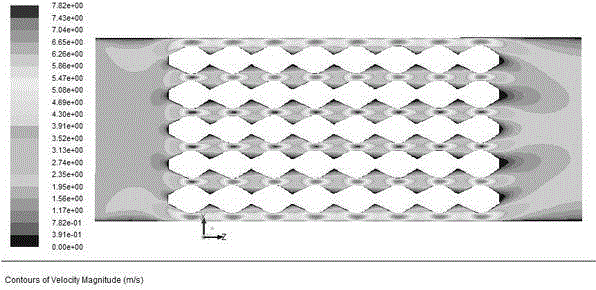

[0021] combine figure 1 , Image 6 As shown, this new partial pressure injection tool is a pressure-reducing groove composed of a throttle core 1, an inner throttle ring column 2, an outer throttle ring column 3, and an outer cylinder 4 coaxially set together from the inside to the outside, that is, The inner throttle ring column 2 surrounds the throttle core 1, the outer throttle ring column 3 surrounds the inner throttle ring column 2, the outer cylinder 4 surrounds the outer throttle ring column 3, the throttle core 1, the inner throttle Both the ring column 2 and the outer throttling ring column 3 have variable cross-sections. Outer cylinder 4 inner diameters are 20mm, (outer cylinder inner diameter sees Figure 5 Middle d10), the annular gap between the outer cylinder 4 and the outer throttle ring column 3 is 0.9mm, the annular gap between the inner throttle ring column 2 and the throttle core 1 is 0.8mm, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com