A kind of overrunning clutch and driving device

A technology of overrunning clutches and one-way clutches, applied to clutches, one-way clutches, mechanical equipment, etc., to achieve the effects of saving manufacturing costs, simple assembly methods, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

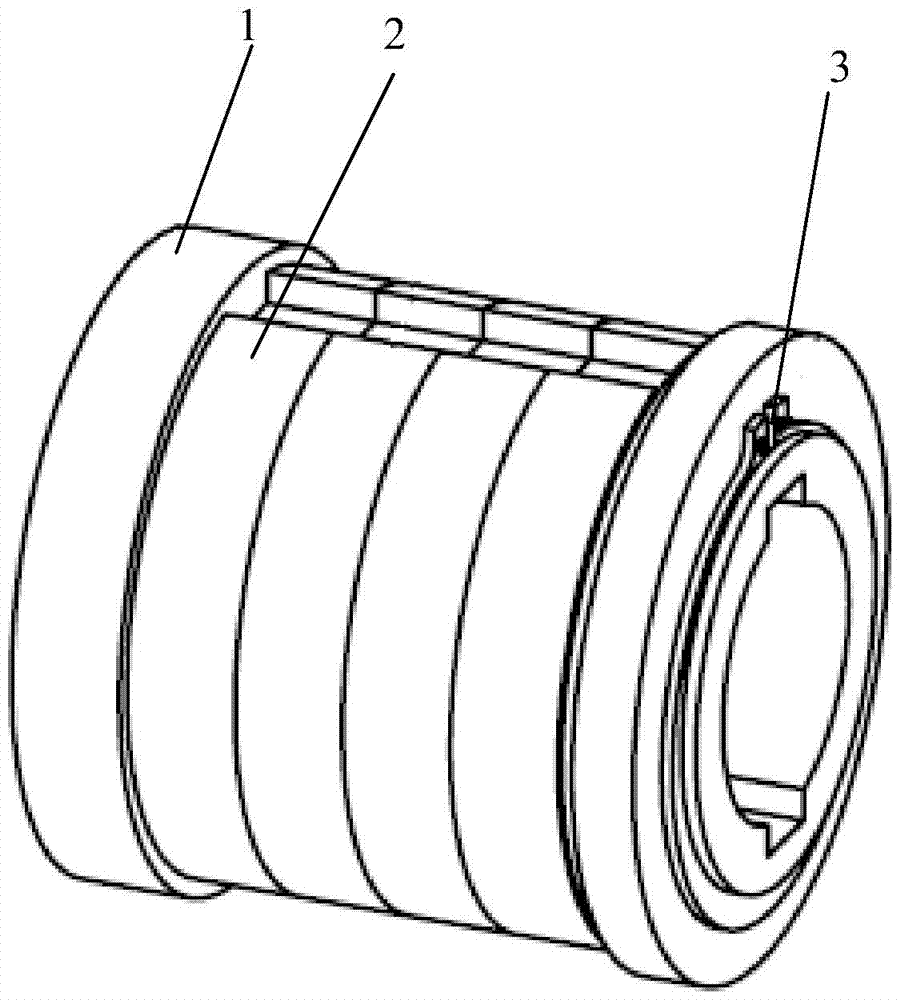

[0031] The embodiment of the present invention provides an overrunning clutch, which is suitable for use in marine gear transmission systems. The system uses multiple hydraulic motors to drive multiple pinion gears, and then these pinion gears drive the same large gear synchronously. See figure 1 , the overrunning clutch includes:

[0032] A shaft sleeve 1, a positioning pin (not marked in the drawings), a plurality of one-way clutches 2 sleeved on the shaft sleeve 1, and a limit mechanism 3 for preventing the one-way clutches 2 from axially moving on the shaft sleeve 1. One end of the sleeve 1 is provided with a radially outwardly extending boss 11 .

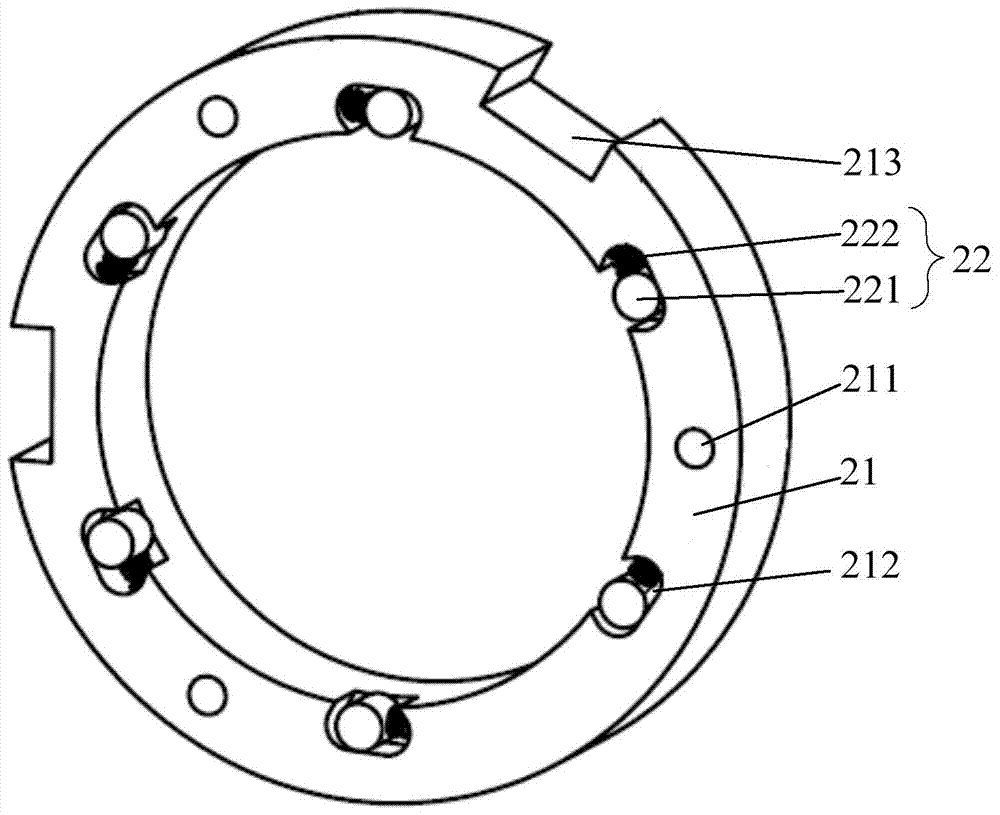

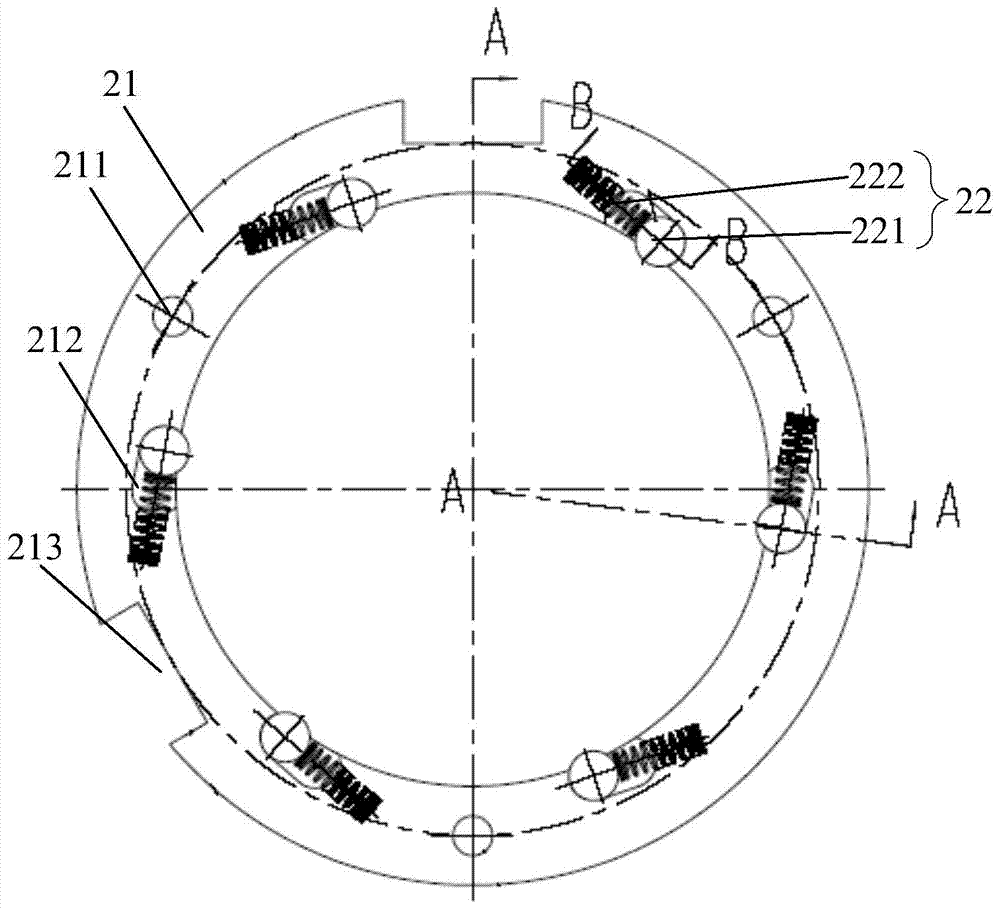

[0033] see figure 2 Each one-way clutch 2 includes: a one-way clutch body 21 and a wetting mechanism 22 for realizing one-way transmission between the one-way clutch 2 and the bushing 1, and the wetting mechanism 22 is installed on the one-way clutch body 21 .

[0034] The one-way clutch body 21 is provided with at least on...

Embodiment 2

[0071] An embodiment of the present invention provides a driving device, see Figure 8 , the driving device includes: a hydraulic motor 4, an overrunning clutch 5 as described in Embodiment 1, and a pinion 6, the overrunning clutch 5 is installed on the output shaft 41 of the hydraulic motor 4, and the pinion 6 is installed on the overrunning clutch 5 .

[0072] Below with reference to the accompanying drawings, the assembly process of an overrunning clutch, pinion 6 and hydraulic motor 4 will be briefly described.

[0073] 1. Assembly process of overrunning clutch 5 and pinion 6.

[0074] see Figure 9, firstly, the wedging mechanism 22 is installed on the one-way clutch body 21, specifically, in this embodiment, the pressing element 222 (for example: a compression spring) is installed in the deep groove part of the groove 212 and installed in the The rollers 221 in the shallow grooves of the grooves 212 are in contact with each other. When the rollers 221 are installed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com