Welding valve zinc alloy piston buffered sea wind power generation instrument

A zinc alloy and piston technology, applied in the field of power generation auxiliary devices, can solve problems such as large resistance and loss, achieve the effect of reducing maintenance costs and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

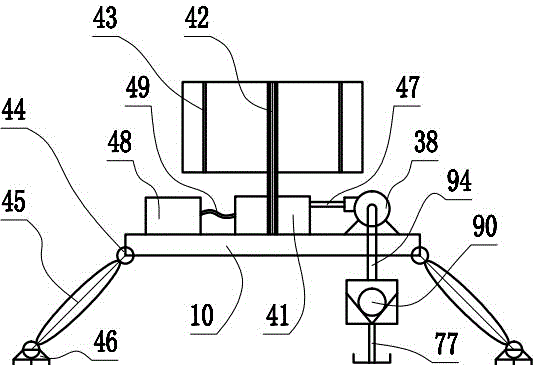

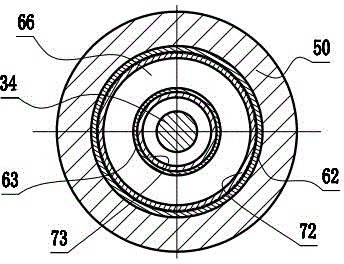

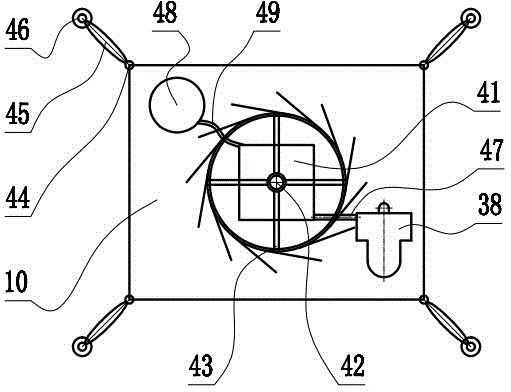

[0035] figure 1, figure 2 and image 3 Middle: a welded valve zinc alloy piston buffering sea wind power generation equipment. There are platform hinges 44 on the four corners of the working platform 10 to connect with the upper hole end of the welding piston two-way buffer 45, and the welding piston two-way buffer 45 lower hole end The head is connected with the fixed foot 46, and the mechanical energy conversion electrical energy unit 41, the energy storage cabinet 48 and the cooling pump 38 are fixedly installed on the operation platform 10, and there is a connection between the energy storage cabinet 48 and the mechanical energy conversion electrical energy unit 41. There is a cooling conduit 47 between the lead wire 49, the discharge port of the cooling pump 38 and the mechanical energy conversion electrical energy unit 41, and the wind rotor shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com