Multi-point distiller's grain sampler and sampling method

A technology of sampler and distiller's grains, which is applied in the field of brewing, can solve the problems of high cost and inconvenient sampling for operators, and achieve the effect of low cost, firm connection, and convenient sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

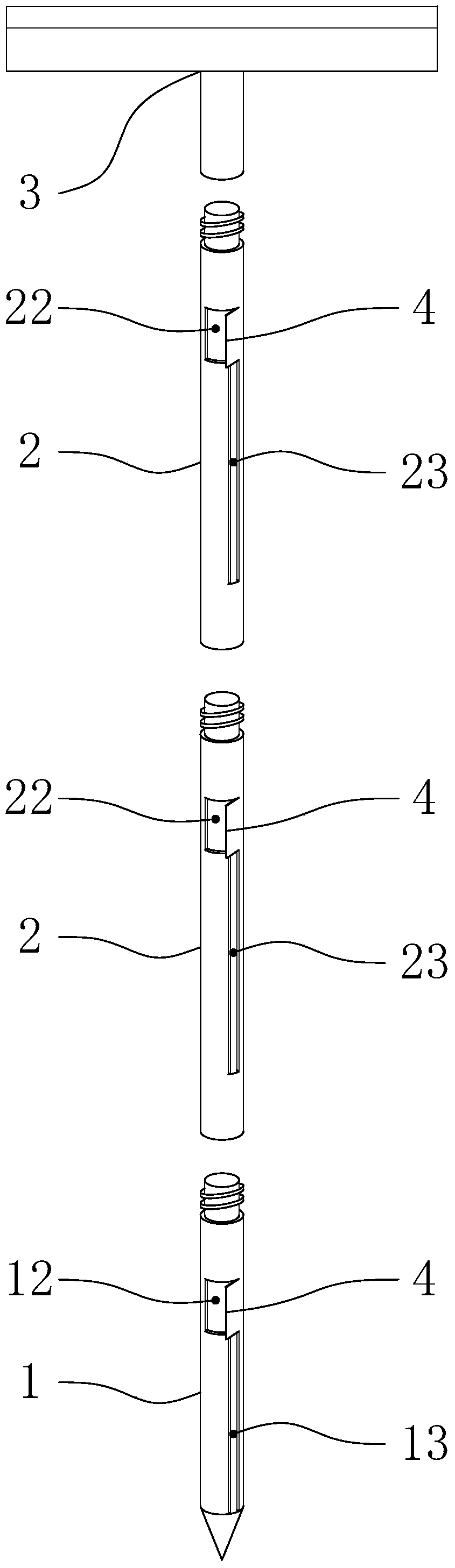

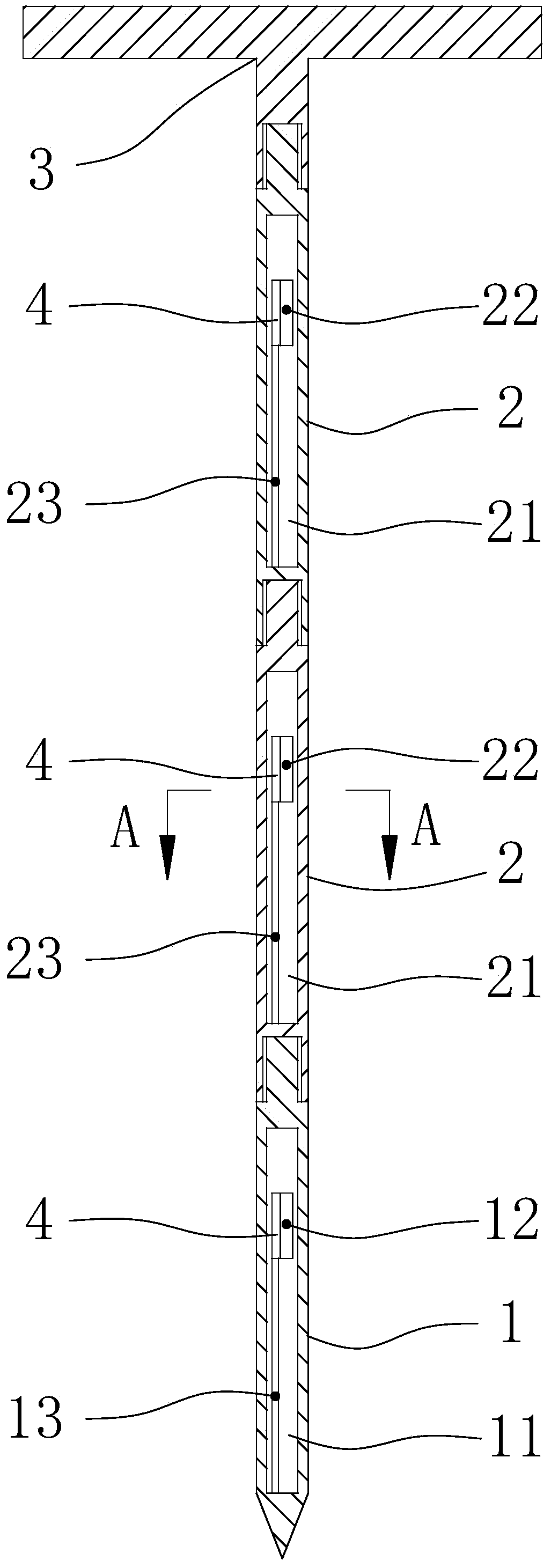

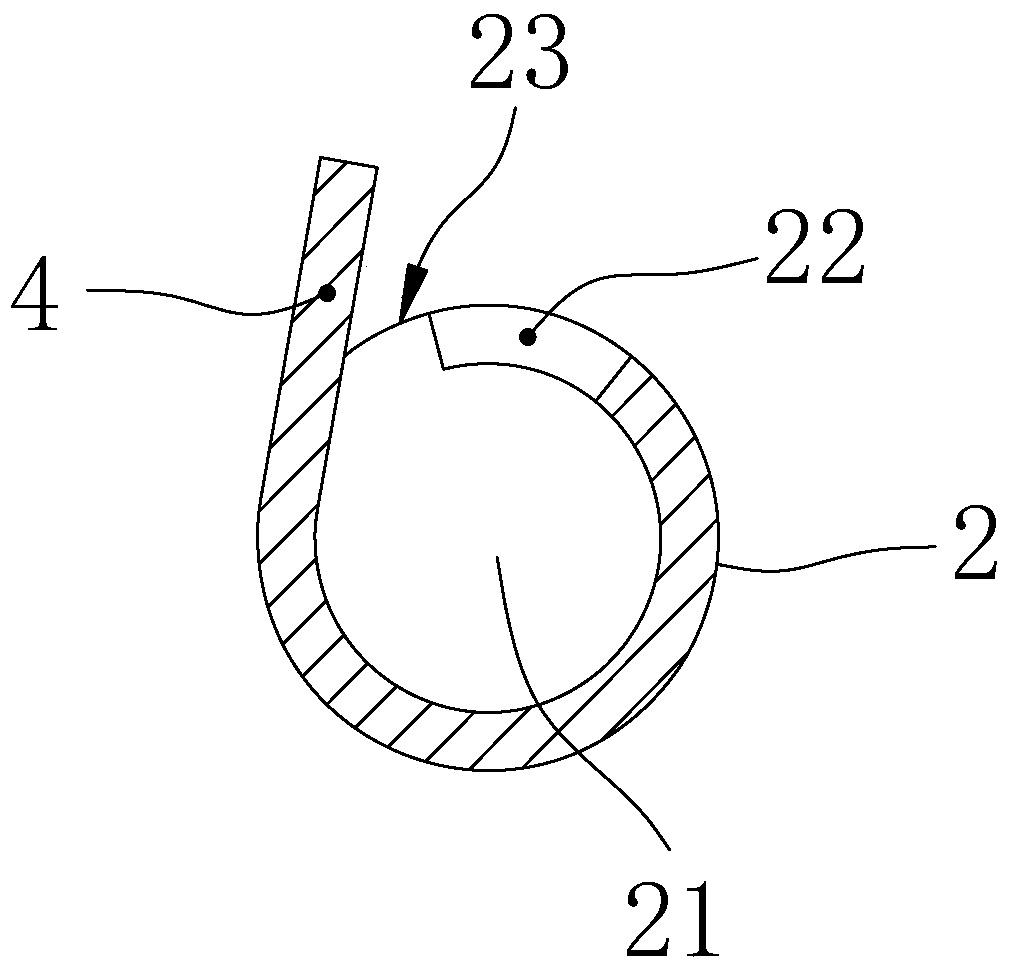

[0038] Multi-point distiller's grain sampler, including the bottom sampling rod 1, the middle sampling rod 2 and the upper handle 3 which are screwed together from bottom to top; the bottom sampling rod 1 and the middle sampling rod 2 are made of stainless steel The formed cylindrical rod has a wall thickness of 0.5 to 0.8 cm;

[0039] The bottom section sampling rod 1 is 1m long and has a cross-sectional diameter of 4-5cm. Its upper end is provided with an external thread, and its lower end is a conical insertion tip with a length of 15cm; Cavity is the bottom segment rod sampling chamber 11, and the outer wall of the bottom segment rod sampling rod 1 is provided with the bottom segment rod sampling port 12 communicated with the bottom segment rod sampling chamber 11, and the vertical side length of the bottom segment rod sampling port 12 is 20cm, wide side The length is 2 to 2.5 cm; a vertical edge of the bottom section rod sampling port 12 is provided with a sampling scrape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com