Fuselage panel combined load test device

A composite load and test device technology, which is applied in the field of strength test technology research, can solve problems such as uneven shear strain, difficulty in test control, and inability to realize the deformation process of fuselage panels, so as to improve the design level and shorten the design cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the fuselage panel composite load test device according to the solution of the present invention, a preferred embodiment of the fuselage panel composite load test device of the present invention will be further described below in conjunction with the accompanying drawings.

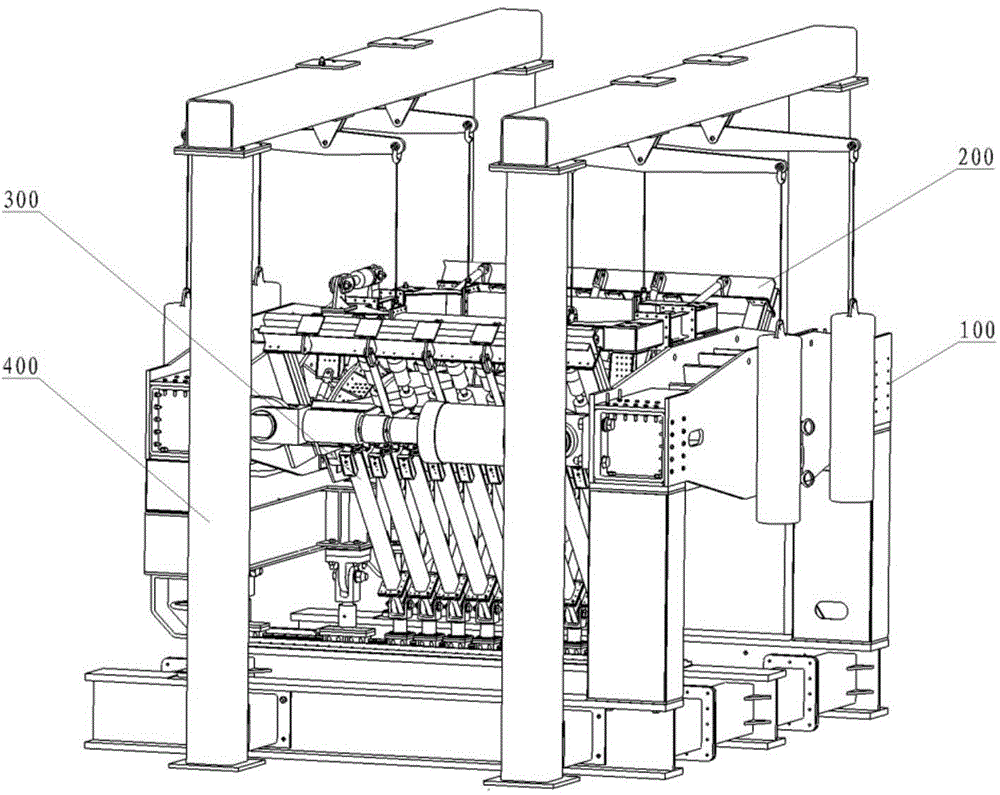

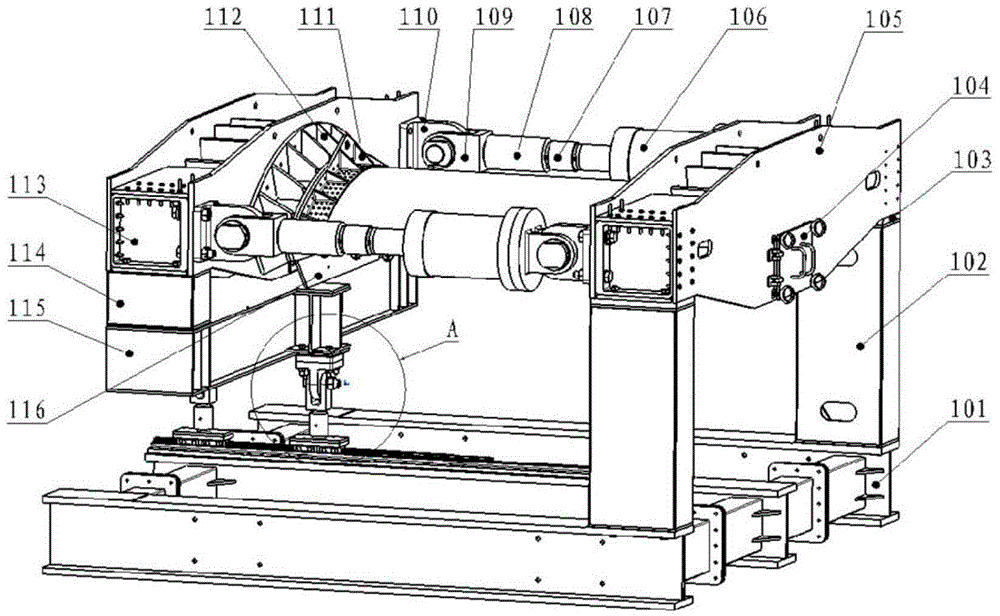

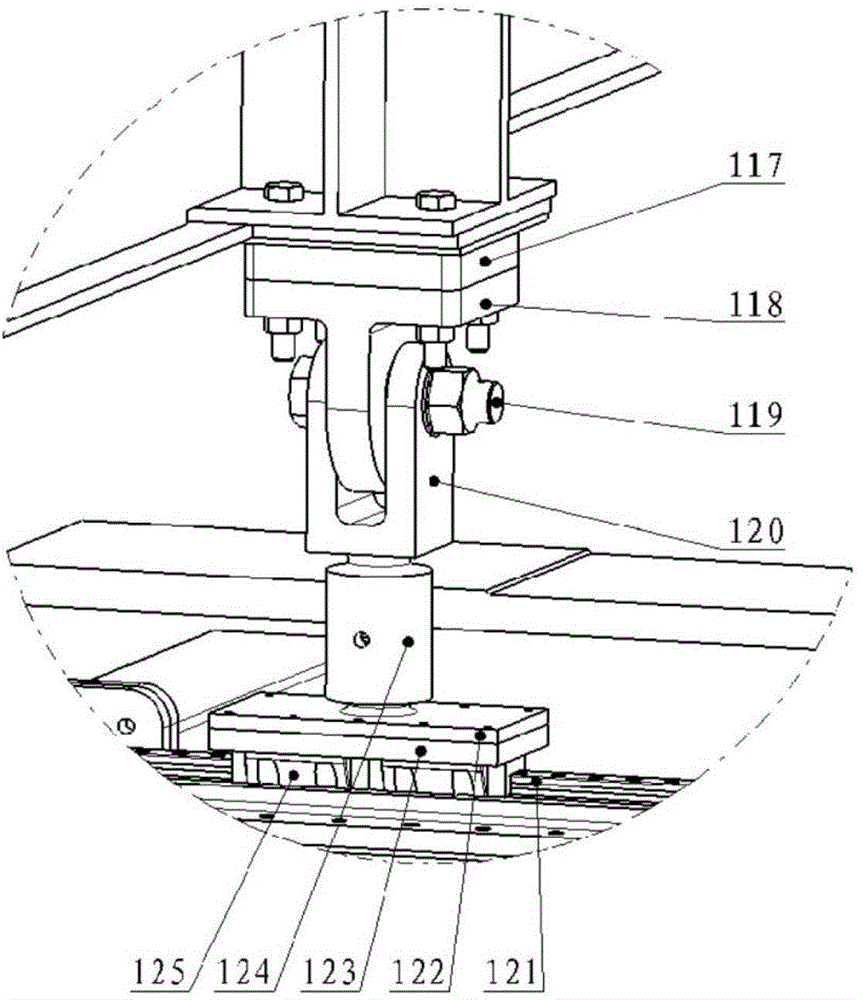

[0031] refer to Figure 1-Figure 12, the fuselage panel composite load test device provided by the present invention includes an axial load application assembly 100, a shear load application assembly 200, an air pressure and hoop load balance assembly 300, and a counterweight assembly 400, wherein the axial load application The assembly 100 is provided with a loading platform 101, a fixed end, a sliding end, and a hydraulic actuator assembly; the shear load application assembly 200 is provided with a straight edge shear load application assembly 1, a curved edge load application assembly 2, and a two-force rod assembly 3. The air pressure and hoop load applying assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com