Method for testing anti-sagging performance of polyurethane wood paint under construction viscosity

A wood coating, anti-sagging technology, applied in the direction of flow characteristics, instruments, measuring devices, etc., can solve the problem of not being able to judge the coating's sag resistance well, not simulating the spraying method, and not directly reflecting the coating's sag resistance. performance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0106] Preparation of general method test device

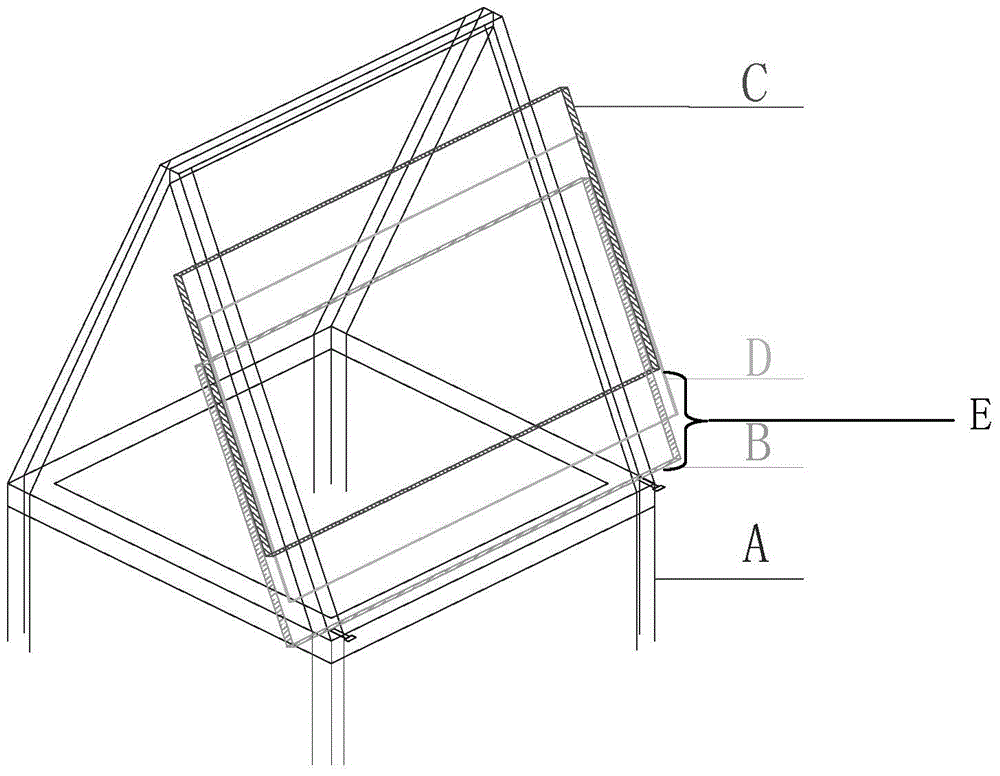

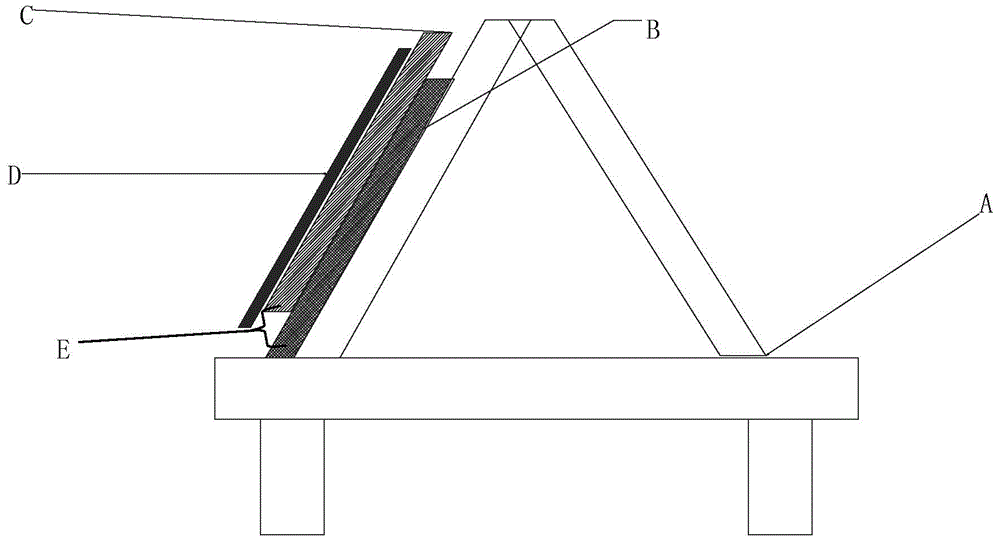

[0107] Prepare to spray the bracket (A), the first backing plate (B), the second backing plate (C), and the A4 tin plate (D), such as figure 1 , 2 As shown, put the second backing board (C) on the first backing board (B), paste the two boards together with a certain distance apart, paste the A4 tin plate (D) on the second backing board (C), A4 The lower end of the tin plate (D) is lower than the lower end of the second backing plate (C) in the middle, but higher than the lower end of the first backing plate (B) on the bottom surface, and the lower end of the first backing plate (B) at the bottom is placed on the spraying bracket (A) above, the test device of the present invention was obtained.

Embodiment 1

[0109] Process and steps in the present embodiment are as follows:

[0110] Take an A4 tin plate, grind the test plate according to the grinding method (according to the national standard GB / T9271-2008), place it according to the spraying device, and apply Yishili environmental protection semi-gloss wood white paint-Yong 48 version according to the construction Adjust the ratio to Tu-4 cup viscosity 16s, and spray the paint evenly from top to bottom according to the wood coating process parameters. 40-60μm, and keep the spraying time, paint output, and gun uniformity consistent; after the first pass of spraying is completed, let it stand for 3 seconds, and then spray the second pass evenly, and proceed in sequence until the bottom of the A4 tinplate plate has Stop spraying when the paint drips out; put the test panel upright in the drying cabinet and wait for the paint film to dry naturally; after the paint film is dry, use a film thickness meter to select 3-5 points to test t...

Embodiment 2

[0125] The process and steps in this embodiment are basically the same as those in Embodiment 1 above. The difference is that the Yishili Environmental Protection Semi-gloss Wooden White Paint White Top Paint is replaced by Jinzhuang Xueyan 8 Series Anti-yellowing Environmental Protection Wooden White Primer, and the anti-sagging dry film thickness of the coating is 145 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com