High-voltage power source quick switching high-voltage switch

A high-voltage switch and fast switching technology, used in high-voltage/high-current switches, electrical switches, high-voltage air circuit breakers, etc., can solve problems such as reduced work efficiency, long switching time, and reduced electrical conductivity, to ensure reliability and stability. The effect of reducing the installation space, simplifying the structure and reducing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (Embodiment 1, fast switching high-voltage switch)

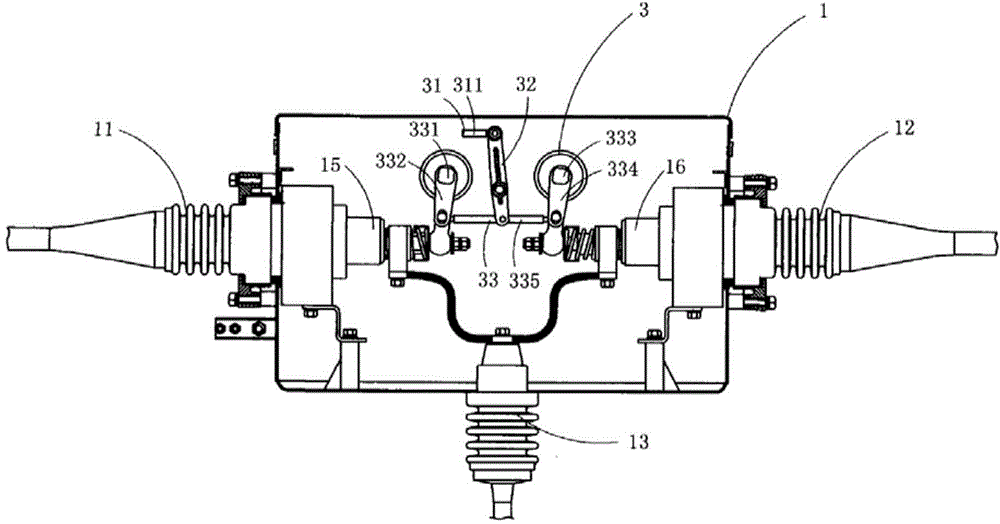

[0018] figure 1 It is a structural schematic diagram of the present invention, showing a specific embodiment of the present invention.

[0019] This embodiment is a fast switching high voltage switch, see figure 1 , including main power terminal 1, auxiliary power terminal 2, outlet terminal 3, switching operation mechanism 4, main vacuum interrupter 5 electrically connected to main power terminal 1, used to drive the main vacuum interrupter 5 The main tripping mechanism 6 for contact movement, the auxiliary vacuum vacuum interrupter 7 electrically connected to the auxiliary power terminal 2, and the auxiliary tripping mechanism 8 for driving the movable contact in the auxiliary vacuum interrupter to move; The switching operation mechanism 4 includes a driving mechanism 41 having a driving arm 411, a lever 42, and an interlocking mechanism 43 for synchronously driving the main tripping mechanism 6 and the se...

Embodiment 2

[0023] (Embodiment 2, high-voltage power supply fast switching method)

[0024] Present embodiment is the working method of above-mentioned embodiment 1, see figure 1 As shown, the main vacuum interrupter 5 for switching on and off the main power supply, the main tripping mechanism 6 for driving the movable contact in the main vacuum interrupter 5 to move, and the auxiliary power supply for switching on and off are provided in the same housing. The auxiliary vacuum interrupter, the auxiliary tripping mechanism 8 for driving the movable contact in the auxiliary vacuum interrupter, the interlock mechanism 43, and the driving mechanism 41; the main vacuum interrupter 5 and the auxiliary vacuum interrupter On the same straight line and arranged symmetrically to each other, the main tripping mechanism 6 and the secondary tripping mechanism 8 are also arranged symmetrically to each other; the driving mechanism 41 drives the main tripping mechanism 6 and the secondary trippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com