Wafer scanning and cleaning swing arm device

A technology of wafer and swing arm shaft, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of cleaning dead angle and poor cleaning effect, and achieve the advantages of reducing electrical connections, large reduction ratio, and enhancing independence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0056] The embodiment of the present invention needs to solve the problem that the swing arm device of the traditional wafer cleaning device only has the scanning and swinging function, the cleaning effect is poor when cleaning the wafer, and there may be cleaning dead spots.

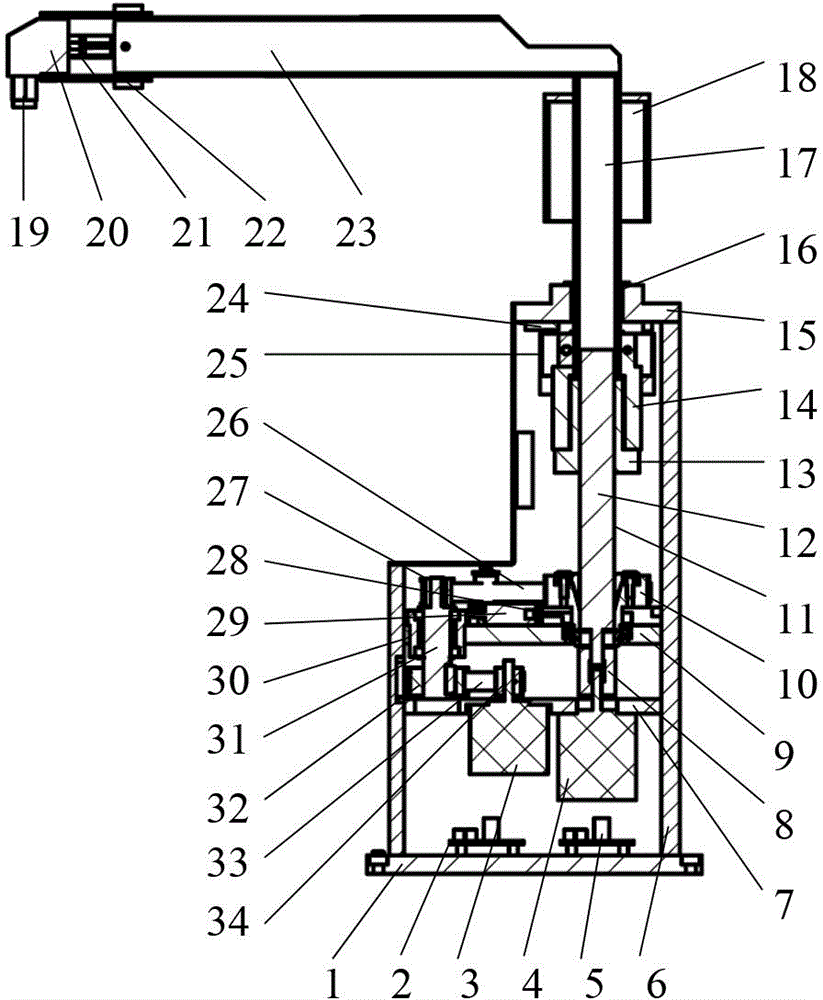

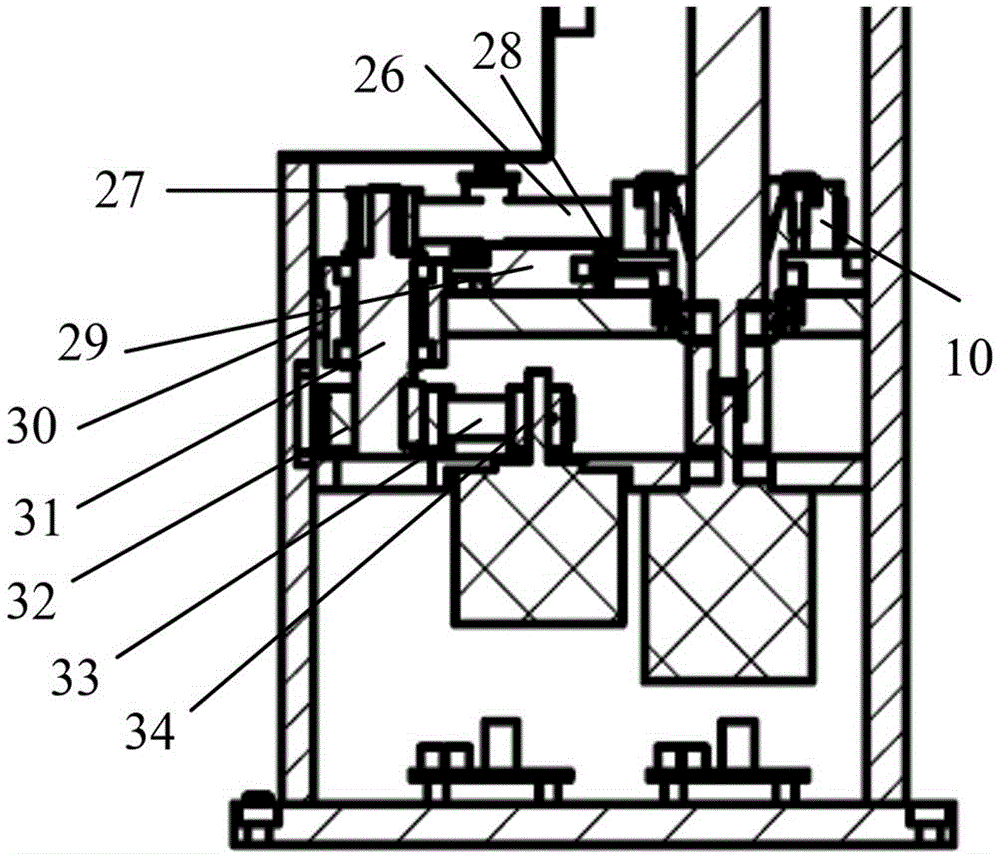

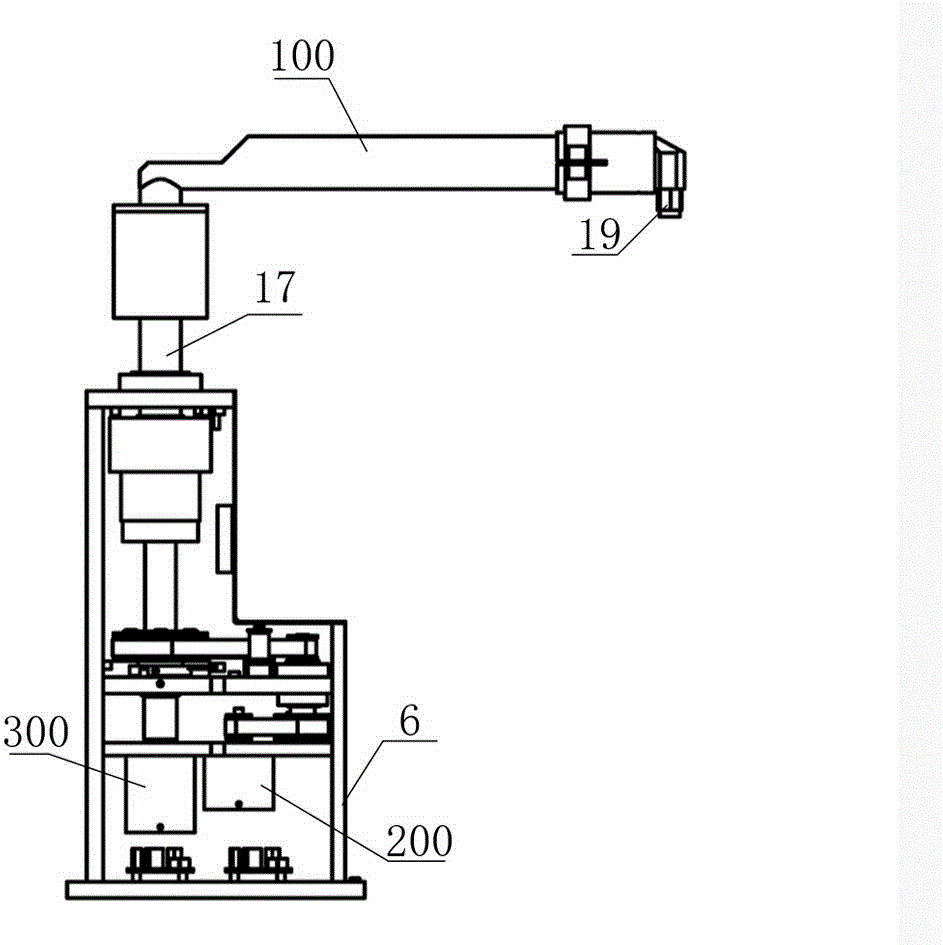

[0057] Such as image 3 As shown, it is a side view of a wafer scanning and cleaning swing arm device provided by an embodiment of the present invention. The wafer scanning cleaning swing arm device includes:

[0058] A swing arm part 100, the swing arm part is provided with a swing arm shaft 17;

[0059] Nozzle 19, the nozzle 19 is installed on the swing arm part 100, and can rotate around the swing arm part 100;

[0060] The lifting part 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com