Microwave heating device and method

A microwave heating device and microwave absorption technology, which is applied in the field of heat treatment, can solve the problems that affect the development of rapid heat treatment technology of non-microwave absorption materials, and there is no progress, and achieve the effect of promoting development and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

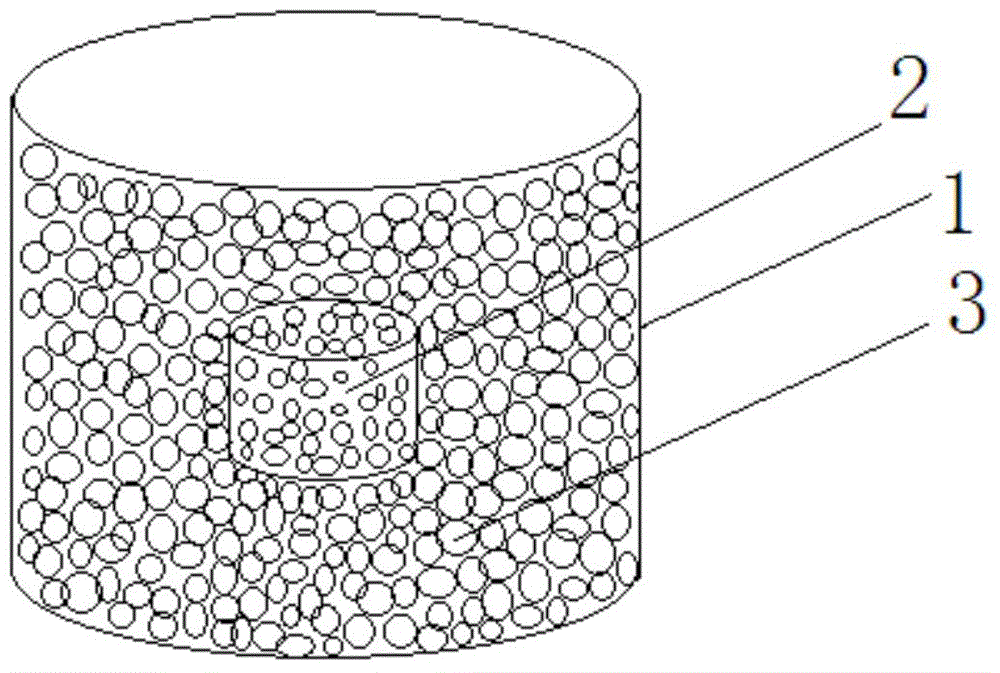

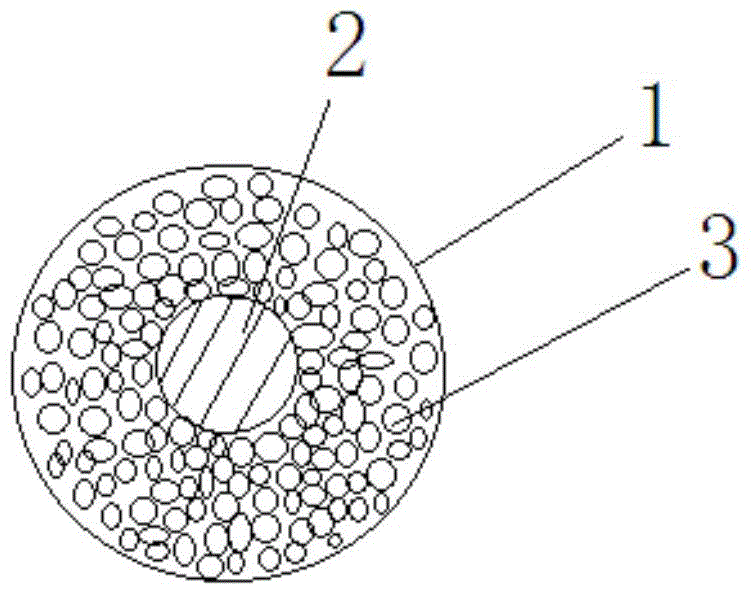

[0038] Such as figure 1 , figure 2 As shown, this embodiment provides a microwave heating device, which is mainly used to achieve the purpose of rapidly heating non-microwave absorbing materials by using microwaves. Specifically, the microwave heating device includes a housing 1, a heat conduction container 2 and a microwave absorbing structure. Wherein, the shell 1 is made of a wave-transparent material for allowing microwaves to penetrate through the shell. The heat-conducting container 2 is arranged in the shell 1, and the heat-conducting container 2 is mainly used for containing the object to be heated, and here, the object to be heated is mainly a non-microwave absorbing material. The microwave absorbing structure is arranged in the shell 1 and contacts the heat conduction container 2 , and is mainly used to absorb microwaves passing through the shell to generate heat, thereby heating the object to be heated in the heat conduction container 2 .

[0039] The microwave ...

Embodiment 2

[0041] Such as figure 1 , figure 2 As shown, this embodiment provides a microwave heating device. Compared with Embodiment 1, the microwave absorbing structure in this embodiment is composed of granular microwave absorbing material 3 filled between the shell 1 and the heat conducting container 2 .

[0042] In this embodiment, the microwave absorbing structure adopts the microwave absorbing material particles surrounding the heat conducting container. Through such arrangement, on the one hand, the particles can fully absorb microwaves, and the heat generated can be fully and evenly transferred to the heat conducting container, realizing the Rapid and uniform heating of the heating object; on the other hand, because the particles are heavier and there are more pores between the particles, even if the gas between the particles heats up sharply, the particles will not leak out; on the other hand, the microwave absorbing material The particles can also act as a support structure ...

Embodiment 3

[0045] This embodiment provides a microwave device. Compared with the above embodiments, the housing in this embodiment includes a housing and a cover. Wherein, the casing is provided with an accommodation cavity, and the accommodation cavity is provided with an opening; the cover body is arranged in cooperation with the opening of the accommodation cavity, and is used to block the opening of the accommodation cavity, so that the accommodation cavity forms a closed space . The heat conducting container and the microwave absorbing structure are accommodated in the accommodating cavity.

[0046] Preferably, the material of the housing is any wave-transparent material among glass, quartz, and heat-insulating bricks; the material of the cover is any wave-transparent material among graphite, glass, quartz, and heat-insulating bricks. These wave-transmitting materials have good wave-transmitting performance and good high-temperature resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com