Casting area moving type dust removing device for continuous casting machine

A mobile dust removal and continuous casting machine technology, which is applied to casting equipment, dust removal, metal processing equipment, etc., can solve problems affecting the quality of billets, rapid drop of molten steel temperature, pollution of the environment, etc., to achieve good dust removal effect and reasonable layout , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

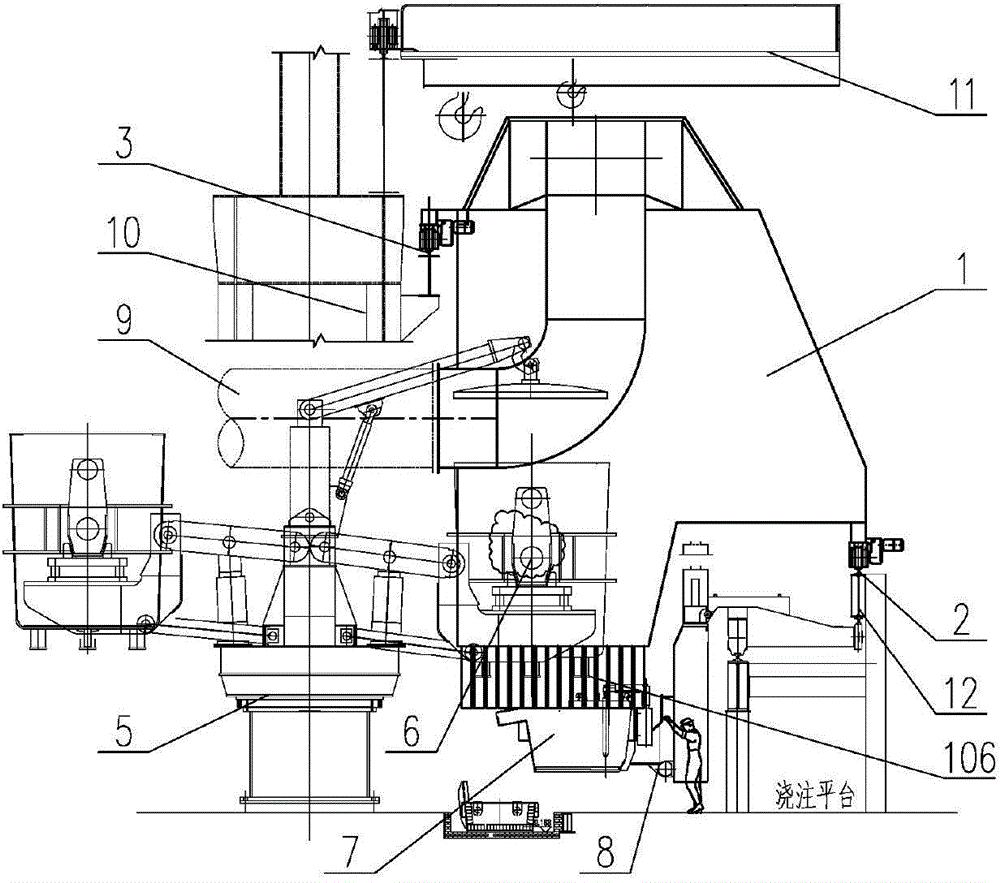

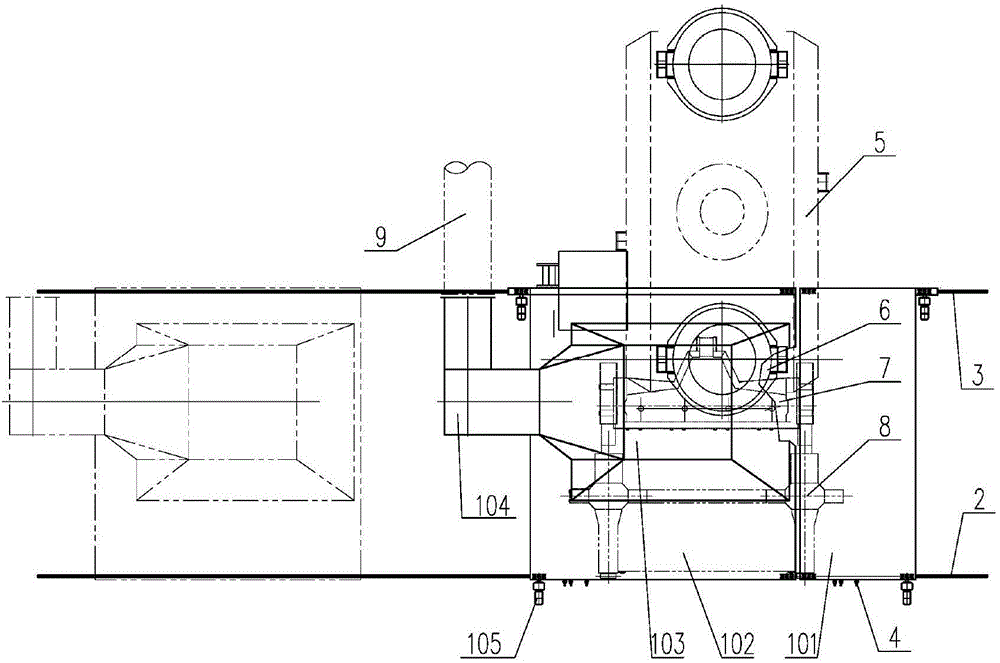

[0017] In this specific embodiment, the mobile dust removal facility in the casting area of the continuous casting machine is composed of a dust collection cover 1 , a low rail 2 and a high rail 3 . like figure 1 and figure 2 As shown, the cover body of the dust collection hood 1 spans the steel ladle and the tundish longitudinally, making full use of the limited height space between the bottom of the beam of the crown block 11 and the top of the ladle turret 5 to form a dust collection space, so as to facilitate the collection of rising and diffusing smoke. Gas; the horizontal letter includes the ladle turntable 5 and the tundish car 8, meeting the high / low rotation requirements of the ladle on the turntable 5.

[0018] Because of its large c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com