Method for forging heating of T-shaped high temperature alloy GH3617M

A GH3617M, forging heating technology, applied in the field of forging, can solve the problems of short time in high temperature heat preservation state, coarse grains of T-shaped forgings, etc., and achieve the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

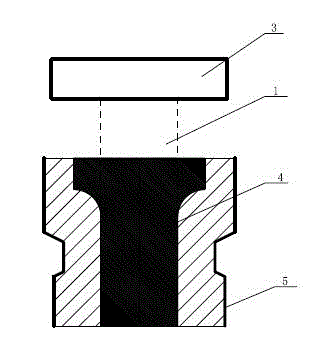

[0024] A T-type superalloy GH3617M forging heating method comprises the following steps:

[0025] Step 1: Place bar 1 in an electric furnace for 15 minutes to keep warm. The temperature of the electric furnace is 150°C. The purpose of preheating the bar is achieved through the heat preservation of the electric furnace, so as to facilitate the subsequent coating work.

[0026] Step 2: Take out the rod 1 obtained from the first step of heat preservation from the electric furnace, and coat one end of the rod 1 with SA-35 glass agent. The coating is applied by spray gun or manual brushing. The above coating The thickness is 1mm.

[0027] The third step: the first heating stage: put the bar material 1 into the electric furnace and raise the temperature to 850-900°C, the holding time is 5-6h, and the heat preservation coefficient is 0.75mm / s.

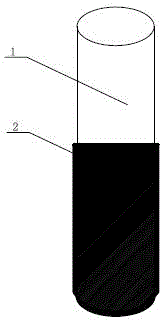

[0028] Step 4: If figure 1 As shown, the rod 1 is taken out, and one end of the rod is covered with thermal insulation cotton 2, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com