Gear shaping processing method of noncircular gear

A non-circular gear and tooth processing technology, applied in the direction of belts/chains/gears, gear teeth, components with teeth, etc., which can solve the problems of complex electrical systems and mechanical devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Here, a pair of sinusoidal transmission ratio third-order non-circular gear transmission is taken as an example, and the processing is carried out according to the above method. The parameters of the gear are shown in Table 1.

[0076] Table 1 Basic parameters of gears

[0077]

[0078] According to the above basic parameters and the basic definition of non-circular gears, the pitch curve of the driving wheel is obtained

[0079]

[0080] Pitch curve of driven wheel:

[0081] Angle of driven wheel:

[0082] Number of teeth of the driven wheel:

[0083] The arc length of the driving pitch curve:

[0084] So the modulus of the gear:

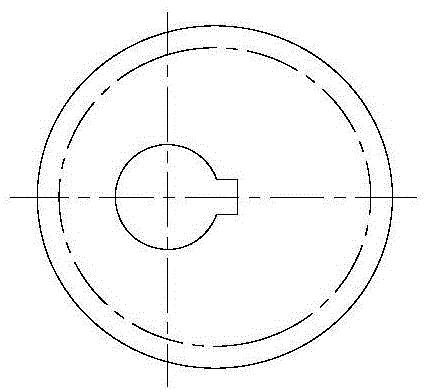

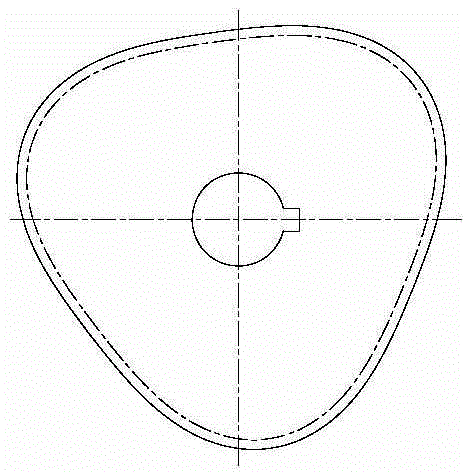

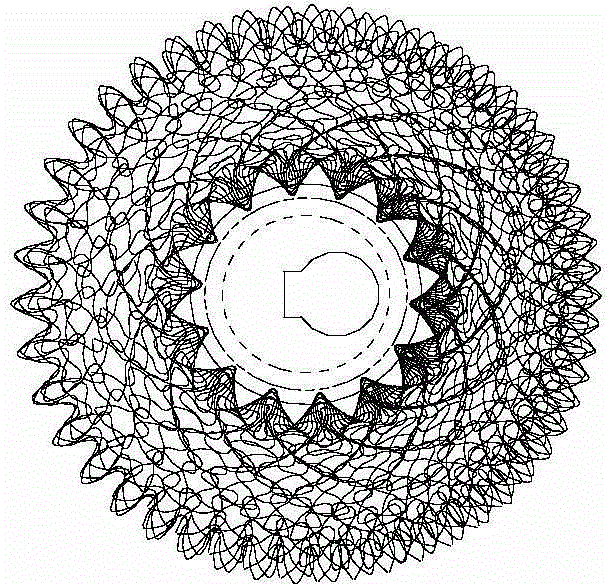

[0085] Calculate the addendum h of the non-circular gear according to Table 1 a =h a * m=2.5, according to formula (3), the wheel blank of non-circular gear can be determined as figure 1 , figure 2 shown. According to the formula (13), the non-circular gear, the starting position of the tool setting of the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com