Hydraulic automatic nut screwing-unscrewing device

A nut and automatic technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of lack of accurate pre-tightening, difficult tightening-unscrewing, high labor intensity, etc., to prolong the life of the device and reduce power The effect of loss and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

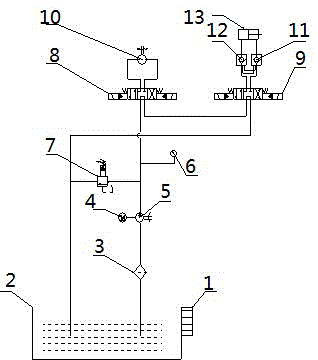

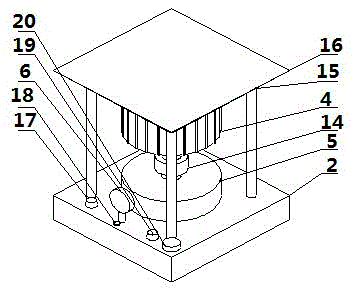

[0047] (1) Check the sealing condition of the device, check the oil level of the oil tank 2, connect the hydraulic pump station to the power supply, start the drive motor 4, and make the first electromagnetic reversing valve 8 and the second electromagnetic reversing valve 9 both in the neutral position, empty Load operation, check the operation of the device.

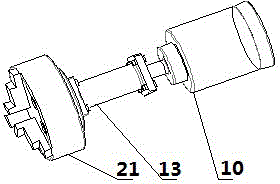

[0048] (2) Start the drive motor 4, adjust the pilot relief valve 7 to set the clamping torque, so that the first electromagnetic reversing valve 8 and the second electromagnetic reversing valve 9 are in the neutral position, and the actuator three-jaw chuck 21 Place it above the nut to be tightened and loosened, and adjust the switch of the second electromagnetic reversing valve 9 to the clamping position. At this time, the hydraulic cylinder 13 drives the three-jaw chuck 21 through the telescopic movement to clamp the nut.

[0049] (3) Turn the switch of the second electromagnetic reversing valve 9 back t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com