Numerical control aluminum alloy pipe cutter

A technology of pipe cutting machine and aluminum alloy, which is applied in the direction of metal processing machinery parts, metal processing equipment, clamping, etc., and can solve problems such as deviation, complex structure of pipe cutting machine, and reduced precision of pipe cutting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

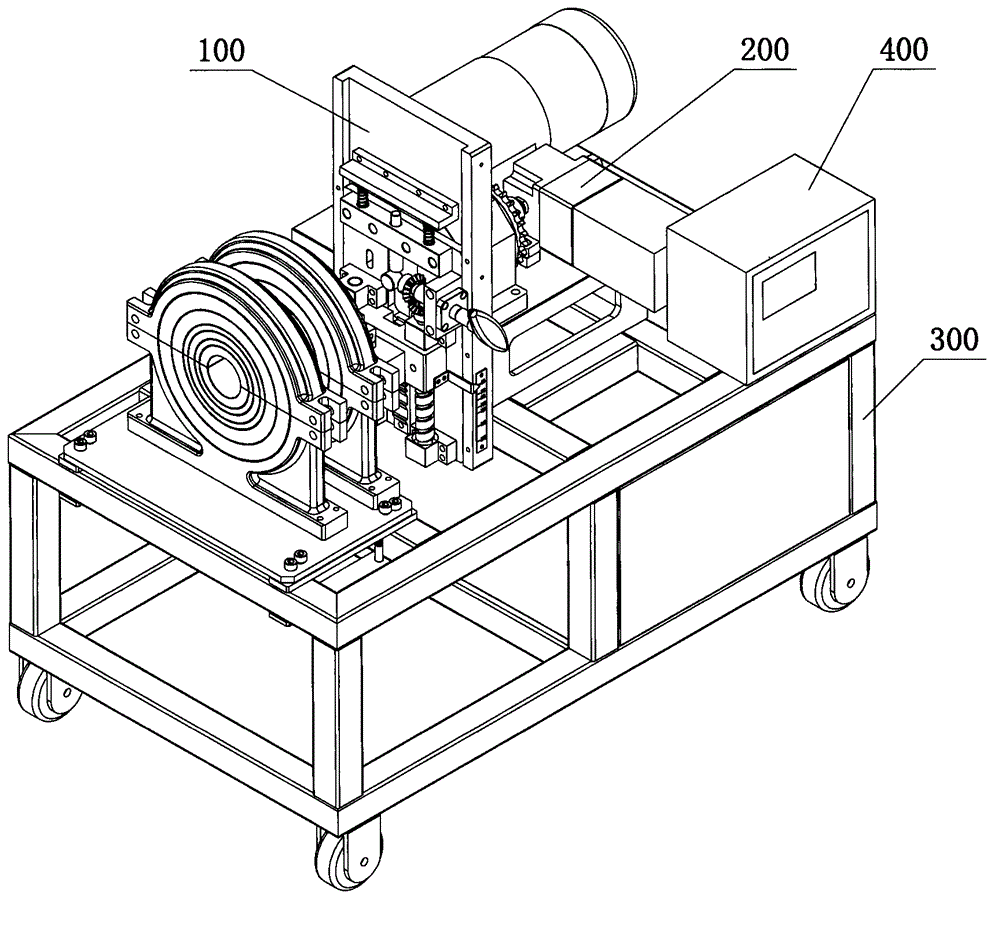

[0024] Such as figure 1 A numerical control aluminum alloy pipe cutting machine is shown, the numerical control aluminum alloy pipe cutting machine includes a numerical control system 400, a flying disc part 100, an installation platform part 200 and a frame part 300, and the flying disc part 100 is arranged on the installation On the platform component 200 , the installation platform component 200 is fixedly arranged on the frame component 300 .

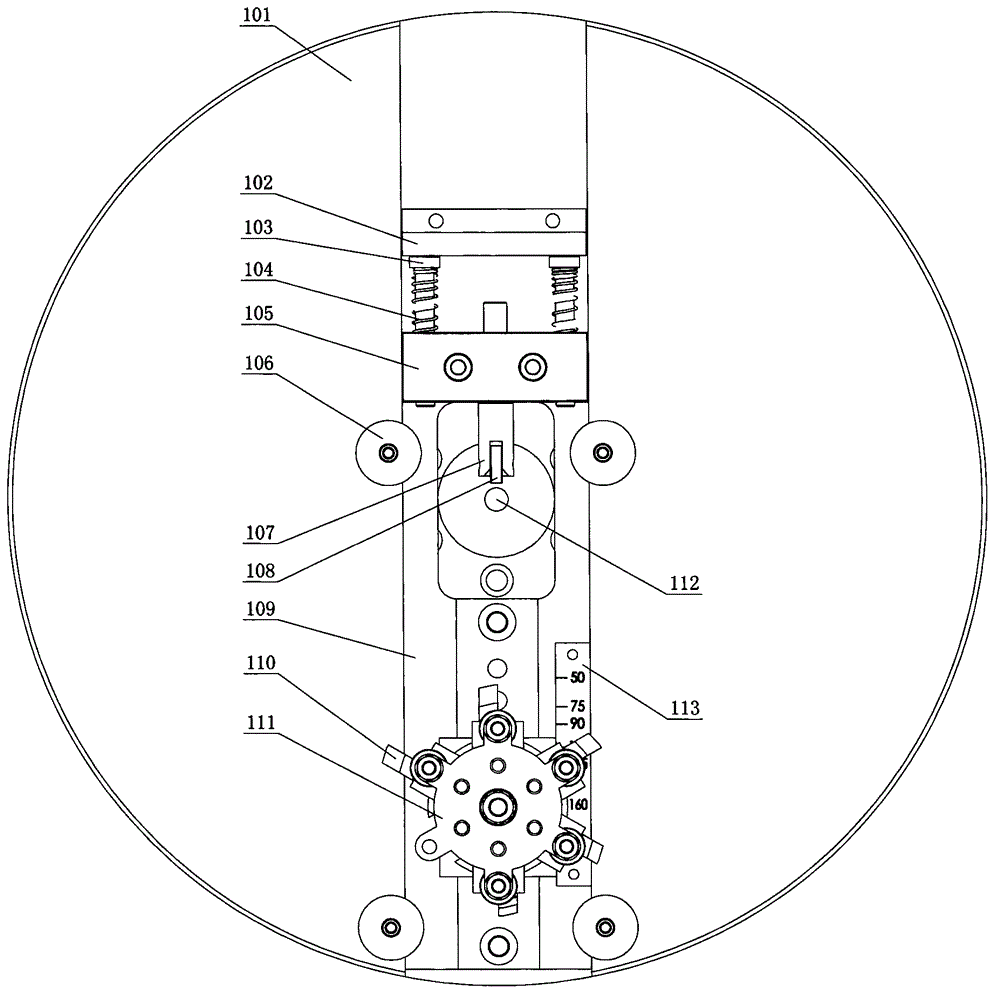

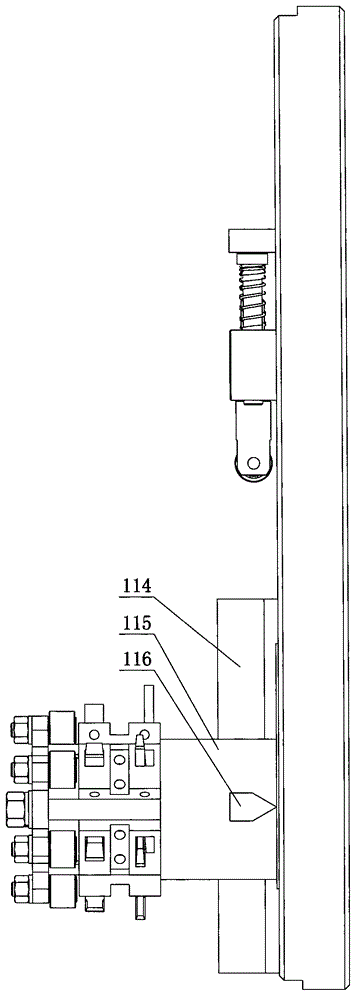

[0025] Such as figure 2 As shown, the flying disc component 100 includes a flying disc 101, a return spring 104 and a return bar 102, a guide groove is set on the flying disc 101, a slide plate 109 is arranged on the guide groove, and a slide plate 109 is arranged on the slide plate 109. The upper end is provided with a guide rail 114, and a slide block 115 is provided on the guide ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap