Adjustable bracket positioning system with heavy load and high precision

A technology for adjusting brackets and positioning systems, applied in hand-held tools, manufacturing tools, etc., can solve problems such as poor load bearing capacity and accuracy, less degrees of freedom, and inability to meet different requirements of different equipment, and achieve fast and convenient positioning and posture Good effect of adjustment and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

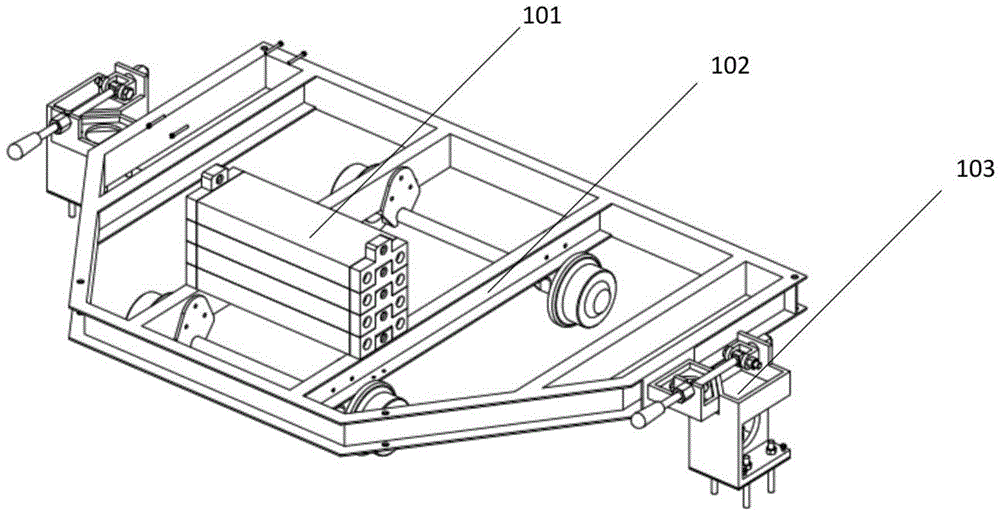

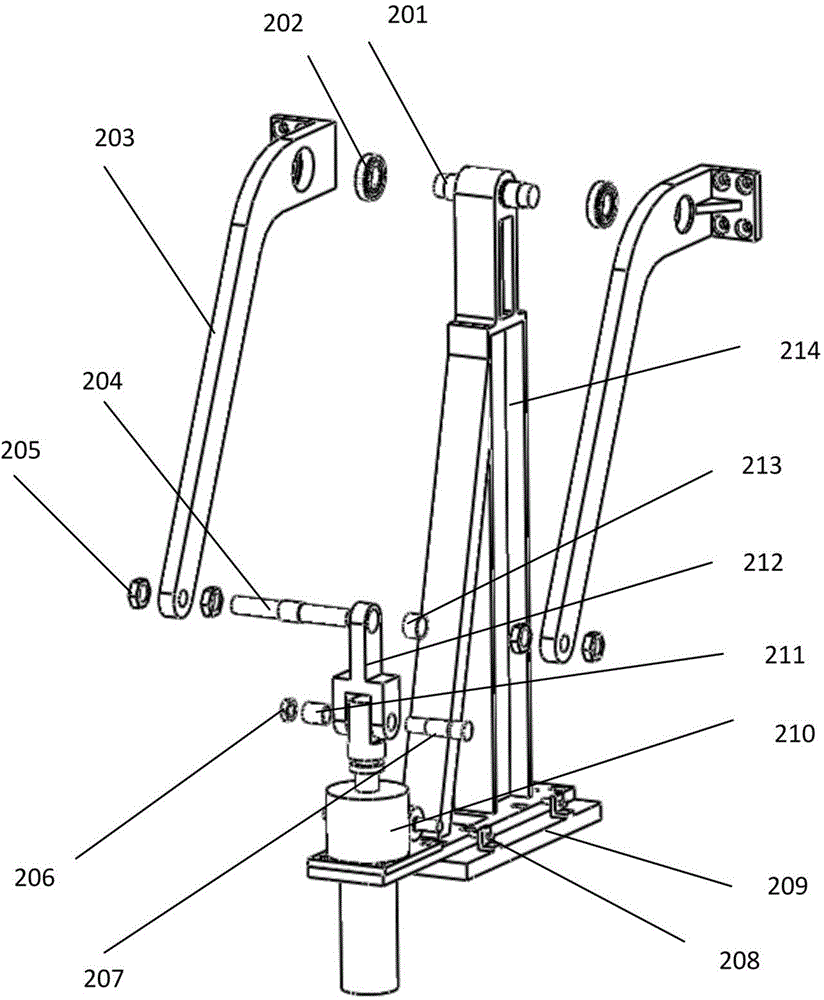

[0038] A large-load high-precision adjustable bracket positioning system of the present invention, such as Image 6 , Figure 7 As shown, it includes a rail car and a wedge block positioning mechanism 1, a pitch adjustment mechanism 2, a roll adjustment mechanism and an arc guide rail 3.

[0039] Rail car and wedge block positioning mechanism 1 comprise rail car 102, counterweight 101 and wedge block positioning mechanism 103, and counterweight 101 is installed on the rail car 102, and wedge block positioning mechanism 103 is symmetrically installed on both sides of rail car 102, as figure 1 shown.

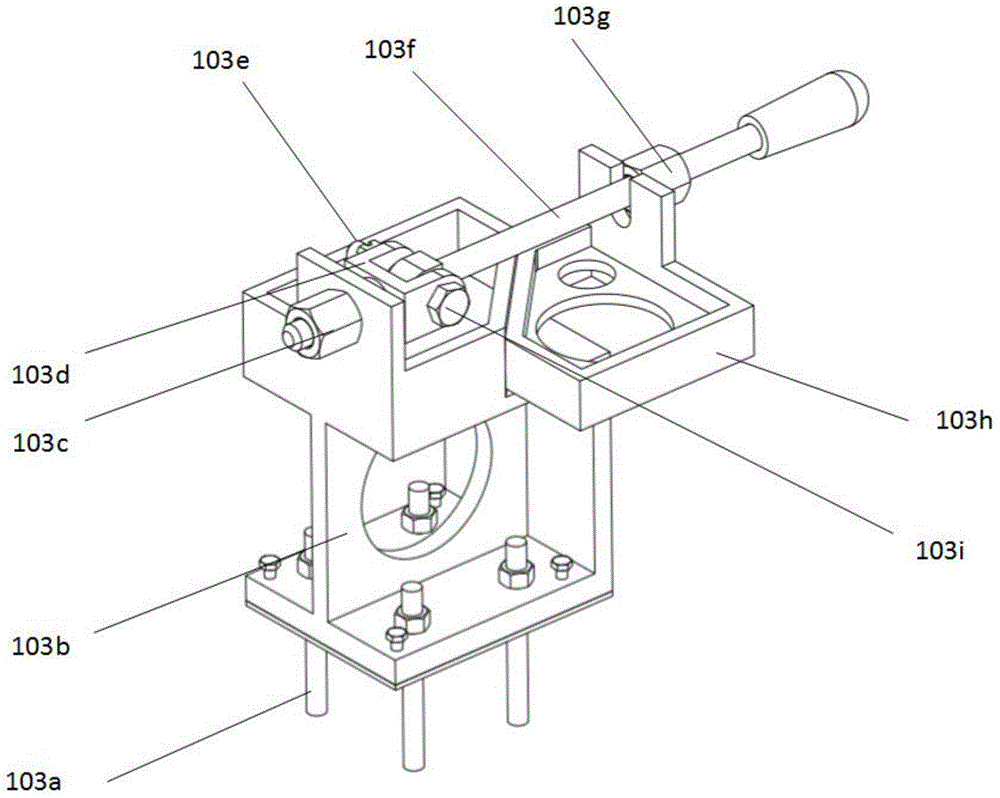

[0040] Wedge block positioning mechanism 103 includes anchor bolt 103a, correction baffle plate 103b, rotating frame mounting nut 103c, screw rod rotating frame 103d, screw rod mounting bolt 103i, screw rod 103f, fixing nut 103g, wedge block 103h, lockn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com