Synchronous lifting device

A technology of synchronous lifting and silk nut, applied in the direction of lifting device, etc., can solve the problems of wasting manpower and time, difficult to adjust height, difficult to adjust height accurately, etc., and achieve the effect of improving efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

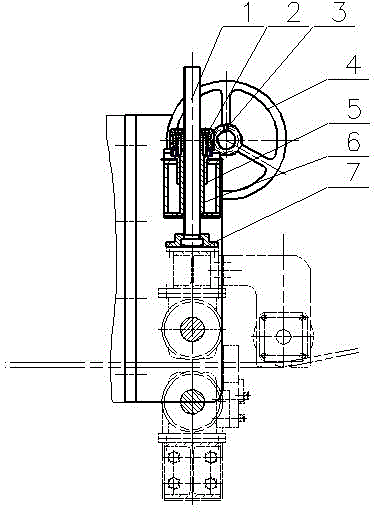

[0011] like figure 1 As shown, the synchronous lifting device includes a screw 1, a worm gear 2, a multi-point synchronous worm 3, a driving handwheel 4, a sliding sleeve 5, a screw nut 6 and a frame 7. The screw 1 is connected to the frame 7, and the worm wheel 2 It is connected with the screw nut 6, the multi-point synchronous worm 3 and the worm wheel 2 are engaged together, the driving handwheel 4 is connected with the multi-point synchronous worm 3, and the worm wheel 2 rotates through the driving hand wheel 4, the lead screw 1 and the multi-point synchronous worm 3, and the screw The nut 6 is installed in the sliding sleeve 5, the nut 6 is connected with the lead screw 1, the relative rotation occurs between the sliding sleeve 5 and the nut 6, and the rotation of the nut 6 drives the lifting and moving of the lead screw 1. The synchronous lifting device of the present invention has a structure Simple and easy to operate Using the conventional transmission device, changin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com