On-line anti-fouling ship ballast water treatment system and ship ballast water treatment method

A ship ballast water and treatment system technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve filter fouling, filter can only be disassembled and cleaned manually And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

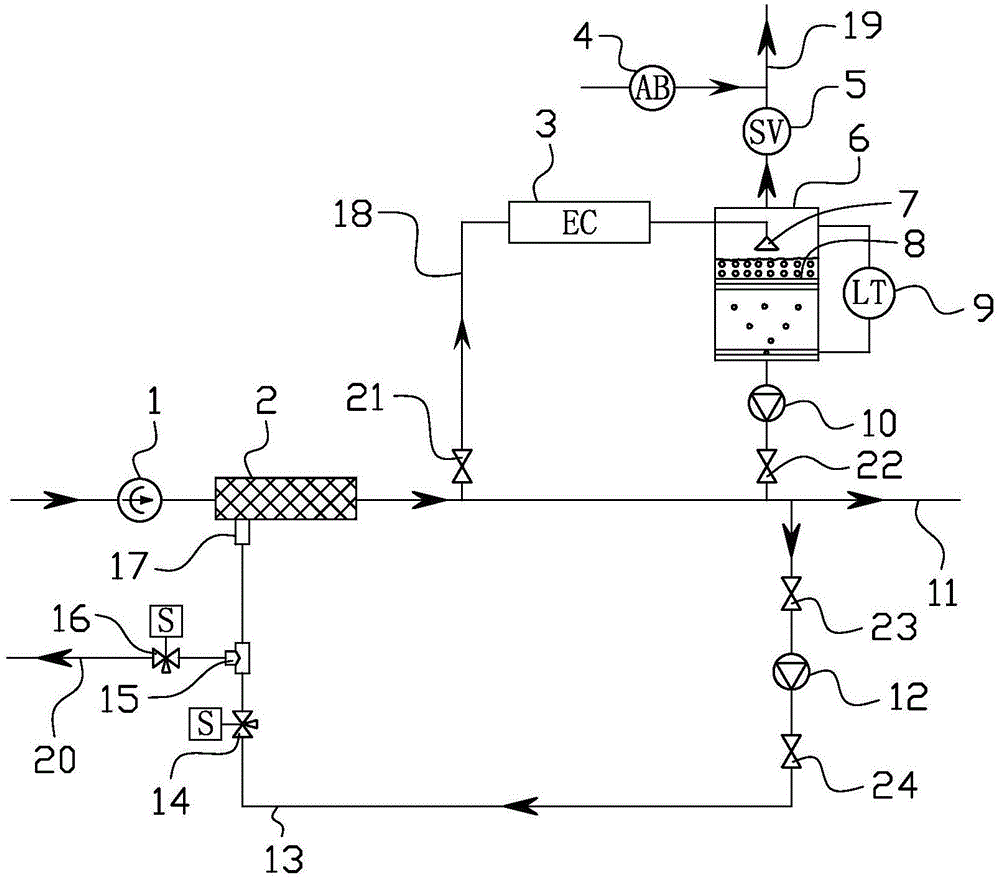

[0036] The antifouling technology of the present invention is applied on a 72000DWT chemical tanker, and the rated flow rate of the ballast pump 1 is 2000m 3 / h. The ship's ballast water treatment system of the present invention is arranged on board see figure 1 .

[0037] A tee joint 15 is installed at the drain outlet 17 of the filter 2, and when the ballasting process ends (i.e. when the ballast pump 1 stops working), a certain amount of water is extracted from the ballast water main pipeline 11 with the second dosing pump 12 The seawater that is filtered and processed by the electrolysis unit 3 is injected into the filter 2 via the dosing pipeline 13 and the three-way joint 15, and the second dosing pump 12 runs for 3 minutes. When the second dosing pump 12 stops running, Close all valves (i.e. the third valve 23, the fourth valve 24 and the first electromagnetic valve 14) connected to the sewage outlet 17 of the filter 2, so that the treated seawater remains in the filt...

Embodiment 2

[0040] The antifouling technology of the present invention is applied on a 350000DWT ore ship, and the rated flow rate of the ballast pump 1 is 4000m 3 / h. The ship's ballast water treatment system of the present invention is arranged on board see figure 1 .

[0041] A tee joint 15 is installed at the drain outlet 17 of the filter 2, and when the ballasting process ends (i.e. when the ballast pump 1 stops working), a certain amount of water is extracted from the ballast water main pipeline 11 with the second dosing pump 12 The seawater that is filtered and processed by the electrolysis unit 3 is injected into the filter 2 via the dosing pipeline 13 and the three-way joint 15, and the second dosing pump 12 runs for 4 minutes. When the second dosing pump 12 stops running, Close all valves (i.e. the third valve 23, the fourth valve 24 and the first electromagnetic valve 14) connected to the sewage outlet 17 of the filter 2, so that the treated seawater remains in the filter 2 u...

Embodiment 3

[0044] The antifouling technology of the present invention is applied on a 180000DWT bulk carrier, and the rated flow rate of the ballast pump 1 is 3000m 3 / h. The ship's ballast water treatment system of the present invention is arranged on board see figure 1 .

[0045] A tee joint 15 is installed at the drain outlet 17 of the filter 2, and when the ballasting process ends (i.e. when the ballast pump 1 stops working), a certain amount of water is extracted from the ballast water main pipeline 11 with the second dosing pump 12 The seawater that is filtered and processed by the electrolysis unit 3 is injected into the filter 2 via the dosing pipeline 13 and the three-way joint 15, and the second dosing pump 12 runs for 5 minutes. When the second dosing pump 12 stops running, Close all valves (i.e. the third valve 23, the fourth valve 24 and the first electromagnetic valve 14) connected to the sewage outlet 17 of the filter 2, so that the treated seawater remains in the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com