Class A inorganic fireproof foam insulation board produced from tailings and preparation method thereof

An insulation board and tailings technology, applied in the field of building insulation, can solve the problems of short service life, high cost, and flammability of B-grade foam insulation boards, achieve strong impact resistance and durability, reduce production raw material costs, and unique The effect of the fire protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

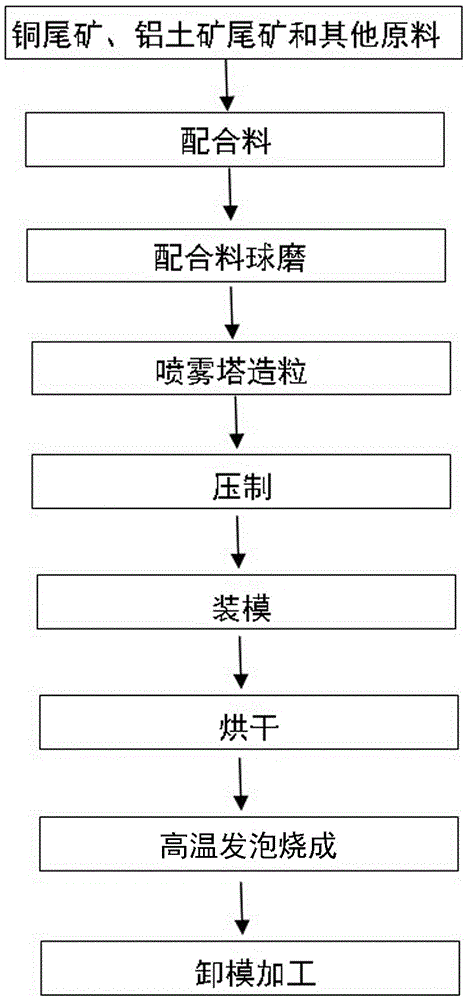

Method used

Image

Examples

Embodiment 1

[0041] The grade A inorganic fireproof foam insulation board produced by tailings, the raw material composition according to weight parts is as follows:

[0042] 40 copies of copper tailings;

[0043] 50 copies of bauxite tailings;

[0044] 4 parts of silica sand;

[0045] 5.5 parts of industrial soda ash;

[0046] High temperature foaming agent 0.5 parts;

[0047] During preparation, the prepared powder is fed into a ball mill and mixed with a certain amount of water to grind for 8 hours. After grinding, the slurry is sent to the spray tower for granulation, and the powder is sent to the press for compression. The shed is surrounded by a refractory baffle with a thickness of more than 200mm. The dryer is pushed to dry at 200℃, and then pushed into the electric furnace or roller kiln for high temperature firing. The firing temperature is 1140℃. After cooling, the mold is unloaded, and the sample is cut into the required specifications according to requirements.

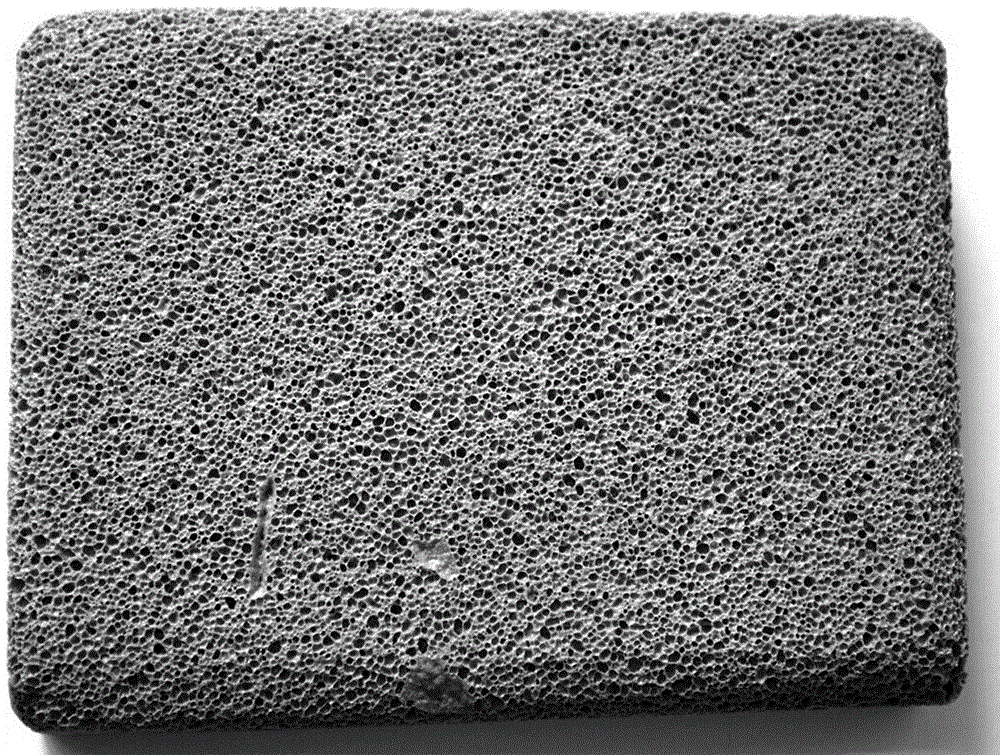

[0048] The Class A inor...

Embodiment 2

[0050] The grade A inorganic fireproof foam insulation board produced by tailings has the following raw material composition according to weight parts:

[0051] 50 copies of copper tailings;

[0052] 40 copies of bauxite tailings;

[0053] 3.2 parts of silica sand;

[0054] 6 parts of industrial soda ash;

[0055] High temperature foaming agent 0.8 parts;

[0056] Send the prepared powder to the ball mill and mix with a certain amount of water for 8 hours. After grinding, send the slurry to the spray tower for granulation. The powder is sent to the press for compression, and the embryo is placed on the fireproof shed. , And surround it with a refractory baffle with a thickness of more than 200mm, push it into the dryer to dry at 200℃, and then push it into the electric furnace or roller kiln for high temperature firing, the firing temperature is 1160℃, and it will be unloaded after cooling. Die, cut the sample into the required specifications according to the requirements.

[0057] The ...

Embodiment 3

[0059] The grade A inorganic fireproof foam insulation board produced from tailings has the following raw material composition according to weight parts:

[0060] 55 copies of copper tailings;

[0061] 33 copies of bauxite tailings;

[0062] 7.8 parts of silica sand;

[0063] 3.2 parts of industrial soda ash;

[0064] 1 part of high temperature foaming agent;

[0065] Send the prepared powder to the ball mill and mix it with a certain amount of water for 8 hours. After grinding, send the slurry to the spray tower for granulation. Send the powder to the press for compression, and place the embryo on the fireproof shed. , And surround it with a refractory baffle greater than 200mm thick, push it into the dryer to dry at 200℃, and then push it into the electric furnace or roller kiln for high temperature firing, the firing temperature is 1165℃, and it will be unloaded after cooling. Die, cut the sample into the required specifications according to the requirements.

[0066] The Class A ino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com