Assembly building and construction method thereof

A construction method and prefabricated technology, applied in the direction of residential construction, architecture, building structure, etc., can solve the problems of slow construction, labor-intensive and time-consuming, etc., and achieve the effect of improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

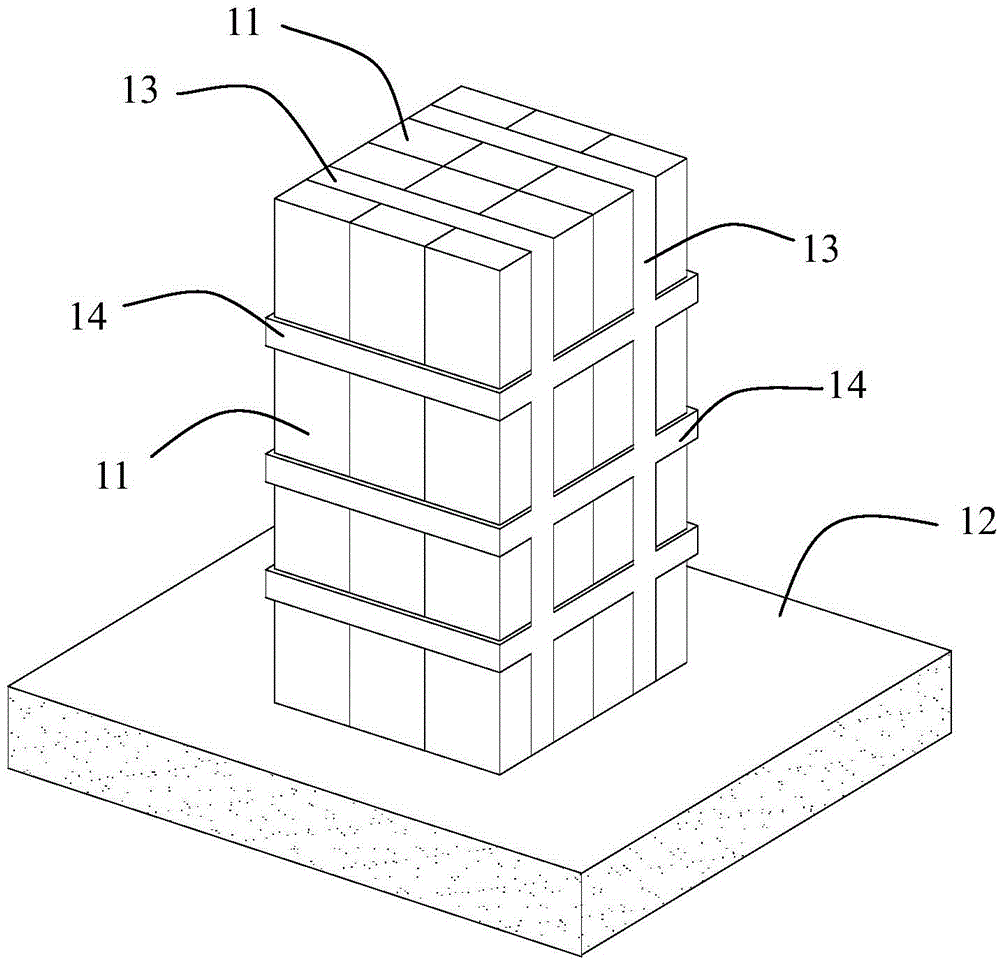

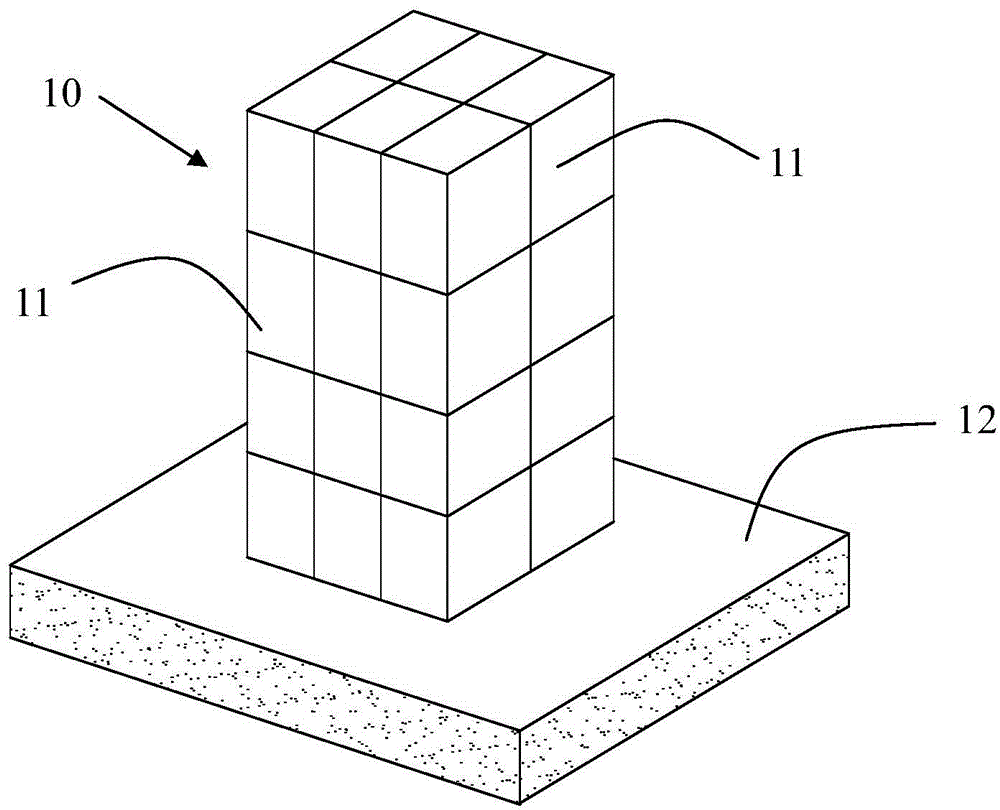

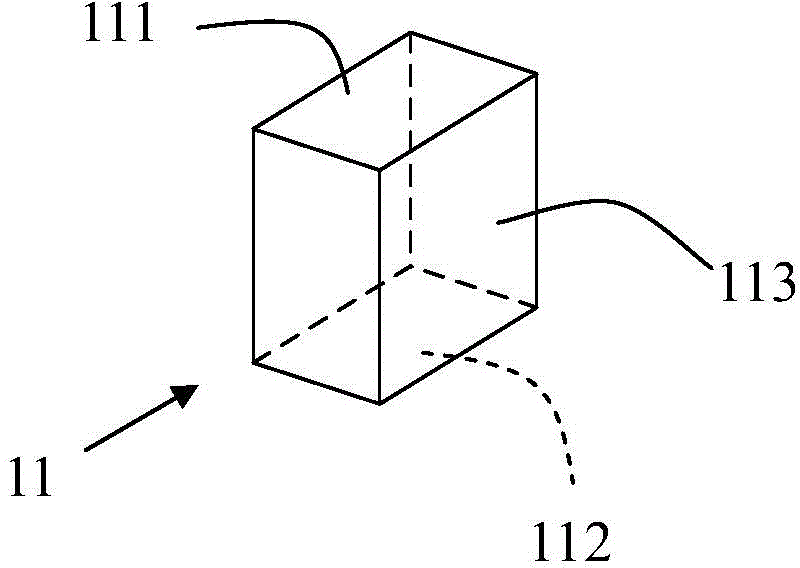

[0047] see first Figure 1~3 As shown, the prefabricated house of the present invention is mainly composed of a plurality of house units 11 that are stacked and connected to form the overall house structure 10, and a fixed structure for fixing the overall house structure 10 on the building foundation 12. In the embodiment, the overall building structure 10 has four floors, six housing units 11 on each floor, and a total of twenty-four housing units 11 . Wherein, each house unit 11 is a house module formed by assembling the roof 111, the bottom board 112 and the wall 113, all of which are prefabricated in a factory. The house unit 11 is equipped with water and electricity facilities, and the internal facilities are complete. Each house unit 11 can be used as an independent residential apartment.

[0048] The fixing structure includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com