Magnetic push electromechanical mixed antitheft alarm lock

An anti-theft alarm and magnetic push technology, applied in the field of anti-theft locks, can solve the problem of not using anti-theft locks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

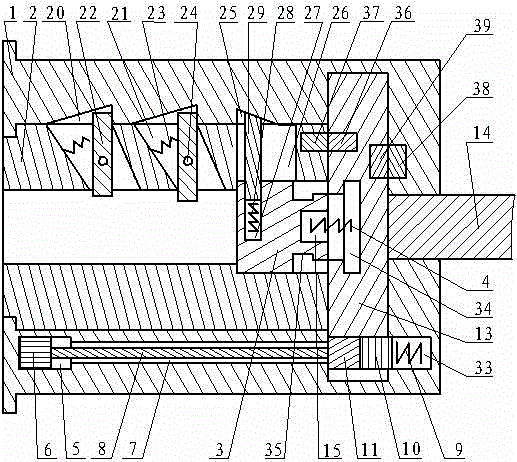

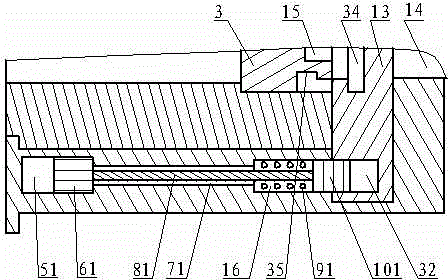

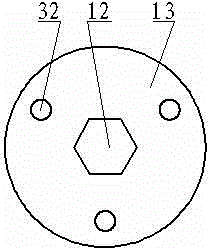

[0076] The magnetic push electromechanical hybrid anti-theft alarm lock of the present invention has a magnetic locking device, an oblique locking device, a horizontal locking device, and a synchronous connection system, with or without an electric insurance anti-theft system, with or without an asynchronous alarm system, and a locking system without a tumbler lock. But it can cooperate with the locking system of the tumbler lock to become a better and safer anti-theft lock; it mainly includes: lock body 1, front lock cylinder 2, rear lock cylinder 13, connector 3, return spring 4, connection hole 12 , Connecting tongue 14, Spring bearing hole 15, Special key hole, Special key, Magnetic push hole 5, Push magnet 6, Slide push hole 7, Push rod 8, Lock hole 32, Push column 11, Push lock head 10. Magnetic push spring 9, magnetic suction hole 51, pull magnet 61, sliding hole 71, spring hole 16, magnetic suction spring 91, pull lock head 101, lock bearing hole 33, chute 21, slant loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com