Time-division and segmental thermal injection production string and method for offshore heavy oil horizontal well

A technology for horizontal wells and oil production pipes, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve the problems that it is difficult to heat the entire well section, reduce centralized heating, and limited device displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

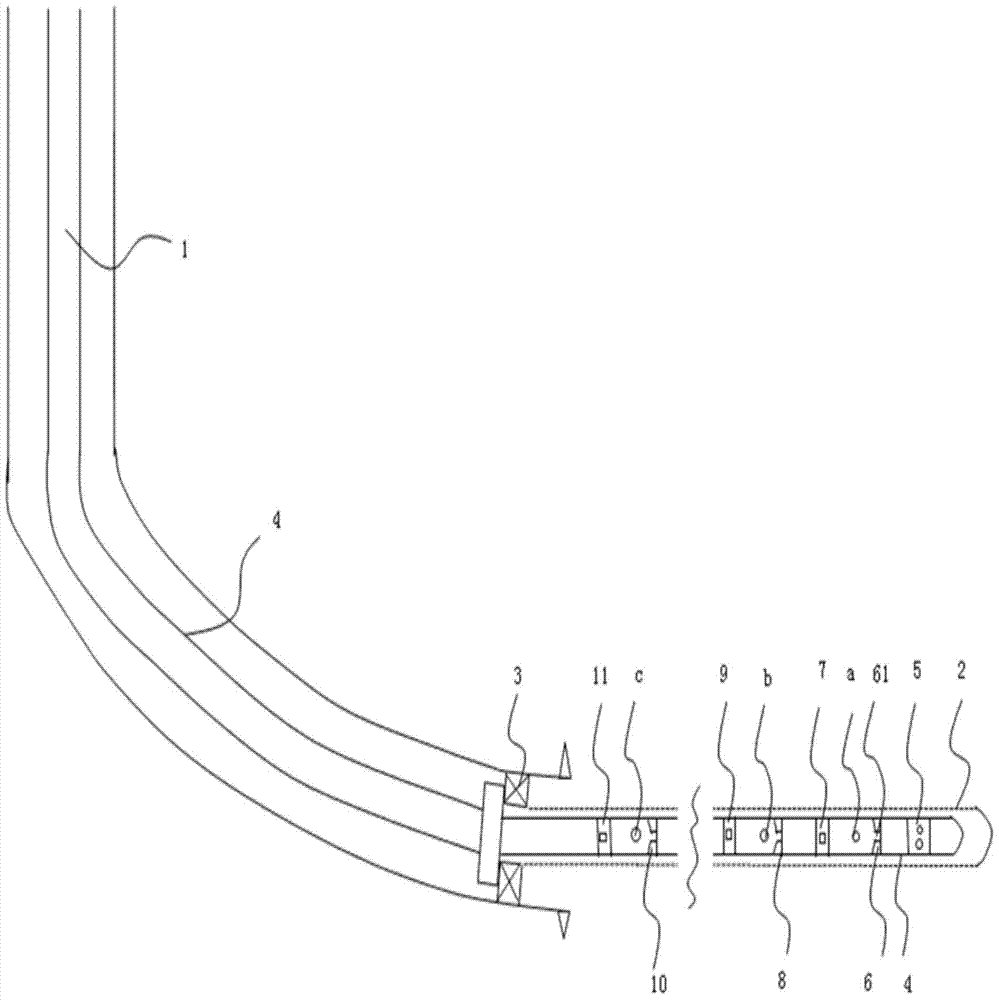

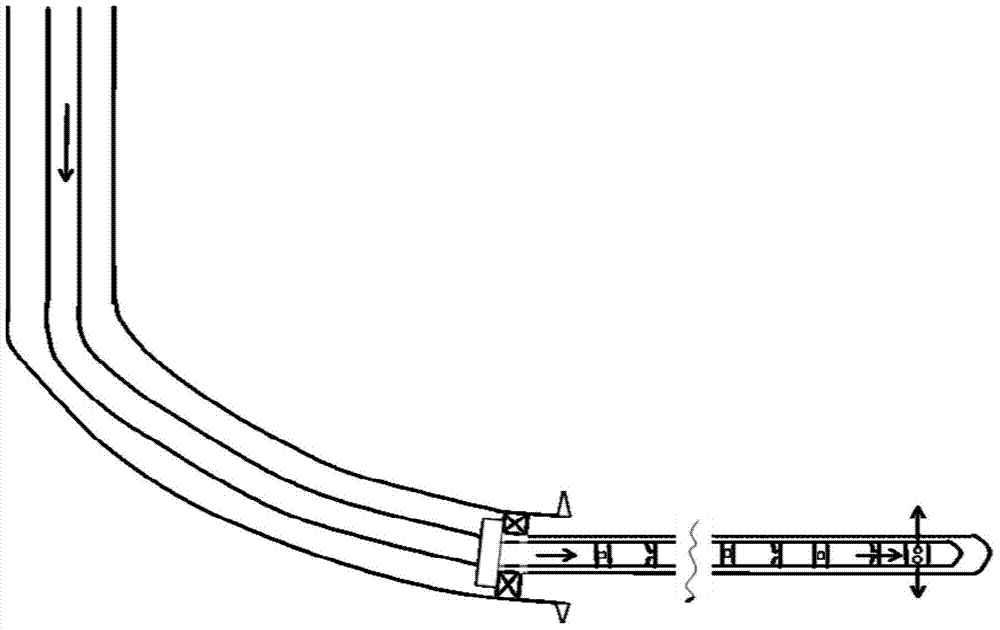

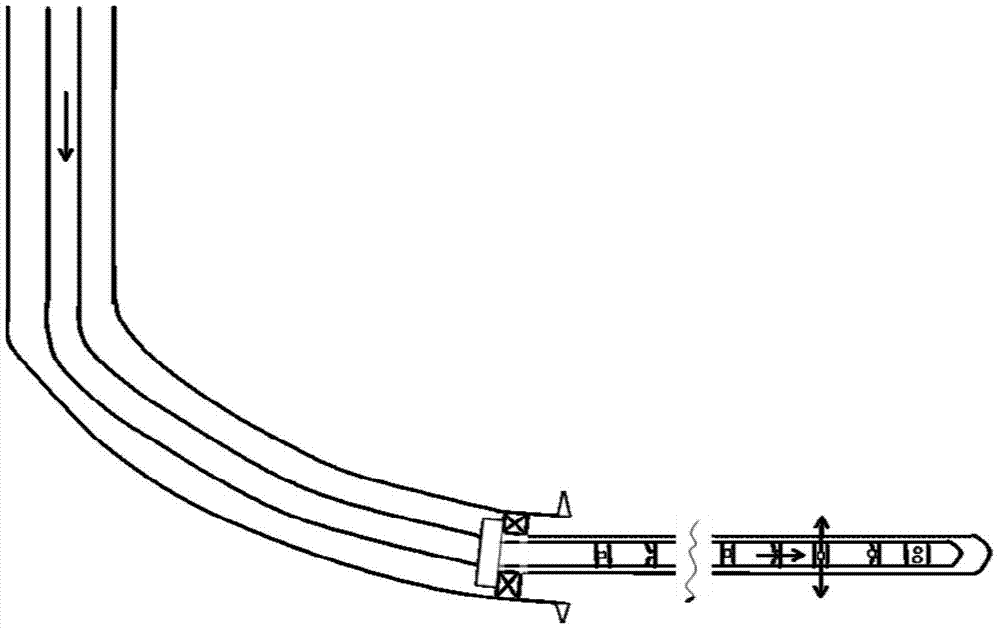

[0016] A pipe string for time-sharing and staged thermal oil recovery of offshore heavy oil horizontal wells according to the present invention includes at least one sand control completion pipe string composed of a central pipe string 1, a sand control screen 2 and a sand control packer 3; the central pipe The free end of the sand control screen 2 at the bottom of the column is sequentially connected with a perforated pipe 5, a No. 1 ball seat 6, a No. 1 pressure rupture disc 7, a No. 2 ball seat 8, and a No. 2 pressure rupture disc 9 through the free end of the oil pipe 4 The ball seat and the pressure rupture disk are connected to the Nth ball seat 10 and the Nth pressure rupture disk 11 according to the length of the horizontal section, and the ball seat has a through hole 61; the first steel ball a, the second steel ball b To the size of N steel ball c and the corresponding through hole of the ball seat;

[0017] From the free end at the bottom of the oil pipe 4 upwards, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com