Heat setting stretching equipment for cloth textile production

A stretching equipment and heat setting technology, which is applied in the elongation of fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of poor stretching and setting effects, uneven heating of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

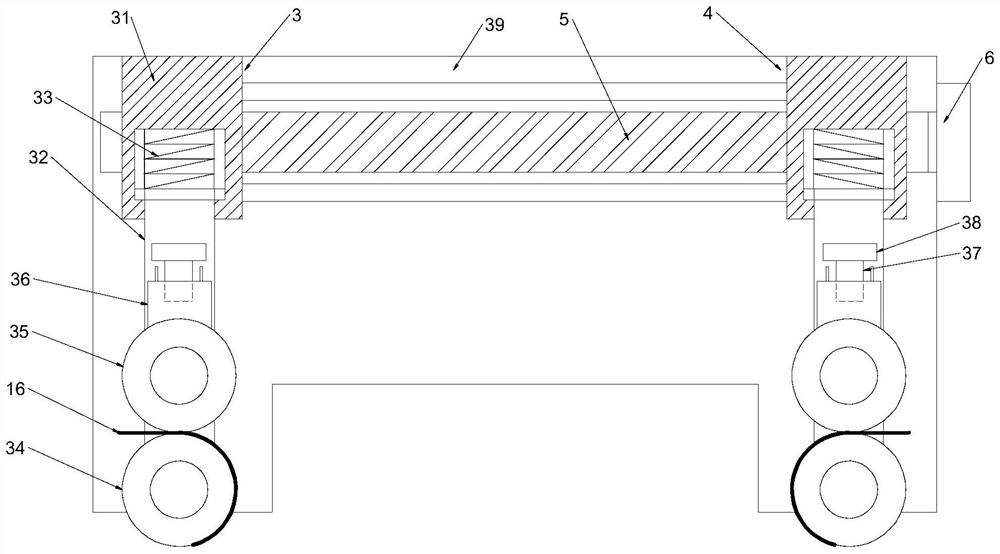

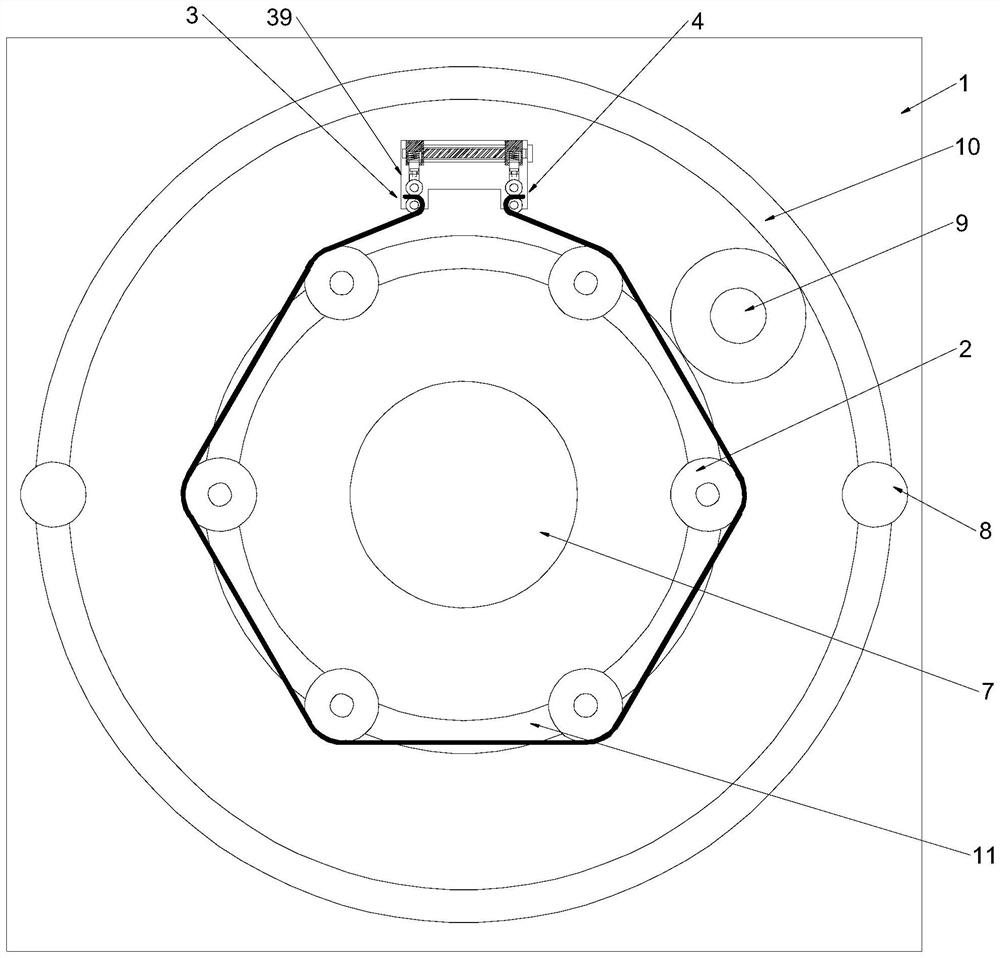

[0025] combine Figure 1 to Figure 2 The shown heat setting stretching equipment for cloth textile production, in this embodiment, includes a stretching box 1, an intermediate support placed in the stretching box 1 and used to prop up the stretched cloth 16 Part 2, used to clamp the cloth inlet nip roller group 3 and the cloth outlet nip roller group 4 at both ends of the cloth supported by the middle support member 2, the cloth inlet nip roller group 3 and the cloth outlet nip roller group 4 are erected and installed on the On the inner walls on both sides of the stretching box body 1, the reverse movement is driven by the driving screw 5 and the driving motor 6 installed at one end of the driving screw 5; the inner walls on both sides of the stretching box 1 are provided with support tables 39 , the cloth feeding nip roller group 3 and the cloth outlet nip roller group 4 all include a nut sliding block 31, an adjusting bottom block 32, an adjusting spring 33, a fixed roller ...

Embodiment 2

[0030] combine Figure 1 to Figure 3 Shown is a heat-setting stretching device for cloth textile production. In this embodiment, the difference from Embodiment 1 is that the intermediate support 2 is rotatably connected to two groups of first rotating rings outside the first rotating ring. The two sets of first ring supports are respectively supported on the two ends of the fabric close to the side wall of the stretching box 1, and a pair of evenly distributed first auxiliary Heating lamp tube 12.

Embodiment 3

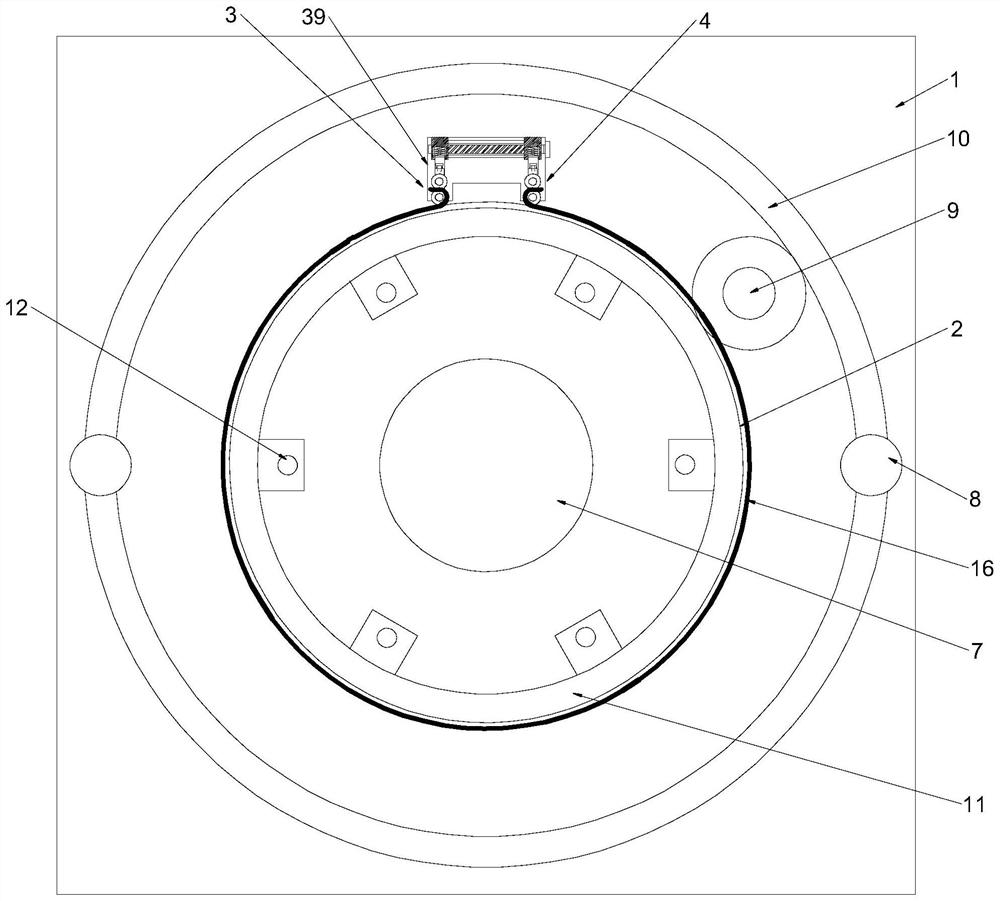

[0032] combine Figure 1 to Figure 4 Shown is a heat-setting stretching device for fabric textile production. In this embodiment, the difference from Embodiment 1 is that the support table 39 is set to rotate around the central heating lamp tube 7 .

[0033] A second rotating motor 13 is installed on the side wall of the stretching box 1, and the support table 39 is installed on the annular second slip ring 14, and the second slip ring 14 is rotatably connected on the inner wall of the stretching box 1, and the second The outer side of the slip ring 14 is provided with a second ring gear which meshes with the second external gear on the second rotating electrical machine 13 for transmission. The intermediate support 2 is a plurality of sets of second supporting rollers erected on the side wall of the stretching box 1 and evenly distributed;

[0034]And because of the settings of the adjustment springs in the cloth feeding nip roller group 3 and the cloth outlet nip roller gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com