Light-emitting device with heat sink composed of two materials

A technology of heat sink and luminescent material, applied in the field of light emitting system, can solve the problems such as the decrease of the light output of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

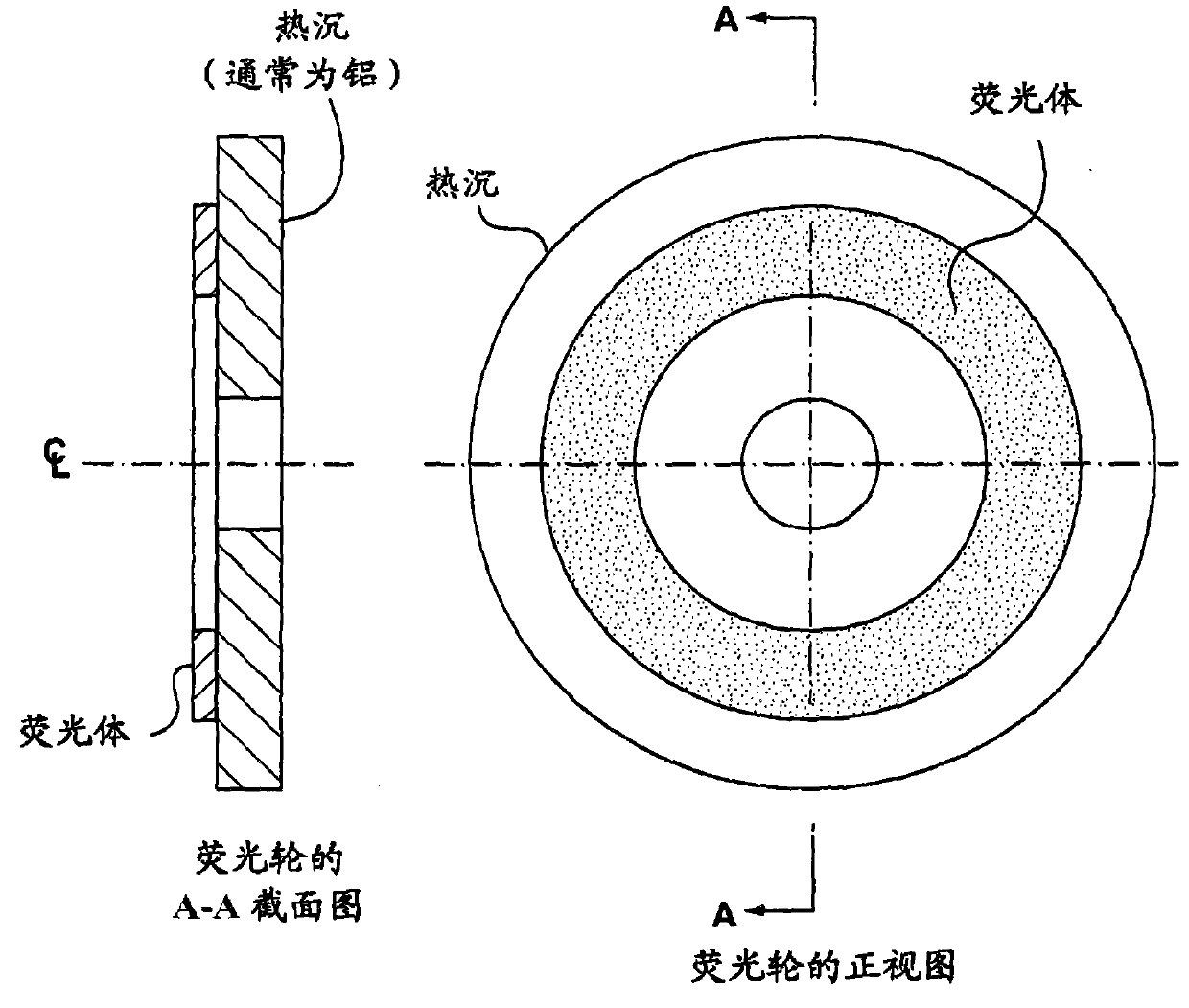

[0038] Fig. 1 shows a front view of a lighting device in the prior art and a cross-sectional view thereof along line A-A. Specifically, the light emitting device includes a phosphor wheel, and the phosphor wheel includes a heat sink (about 1 mm in thickness) and a luminescent material such as a phosphor (about 0.2 mm in thickness). The heat sink may comprise aluminum, which has a higher CTE (about 22 μm / m-K) than that of the phosphor (about 6-7 μm / m-K), which causes the light emitting device to generate heat when the temperature of the light emitting device increases during operation. Mechanical failure.

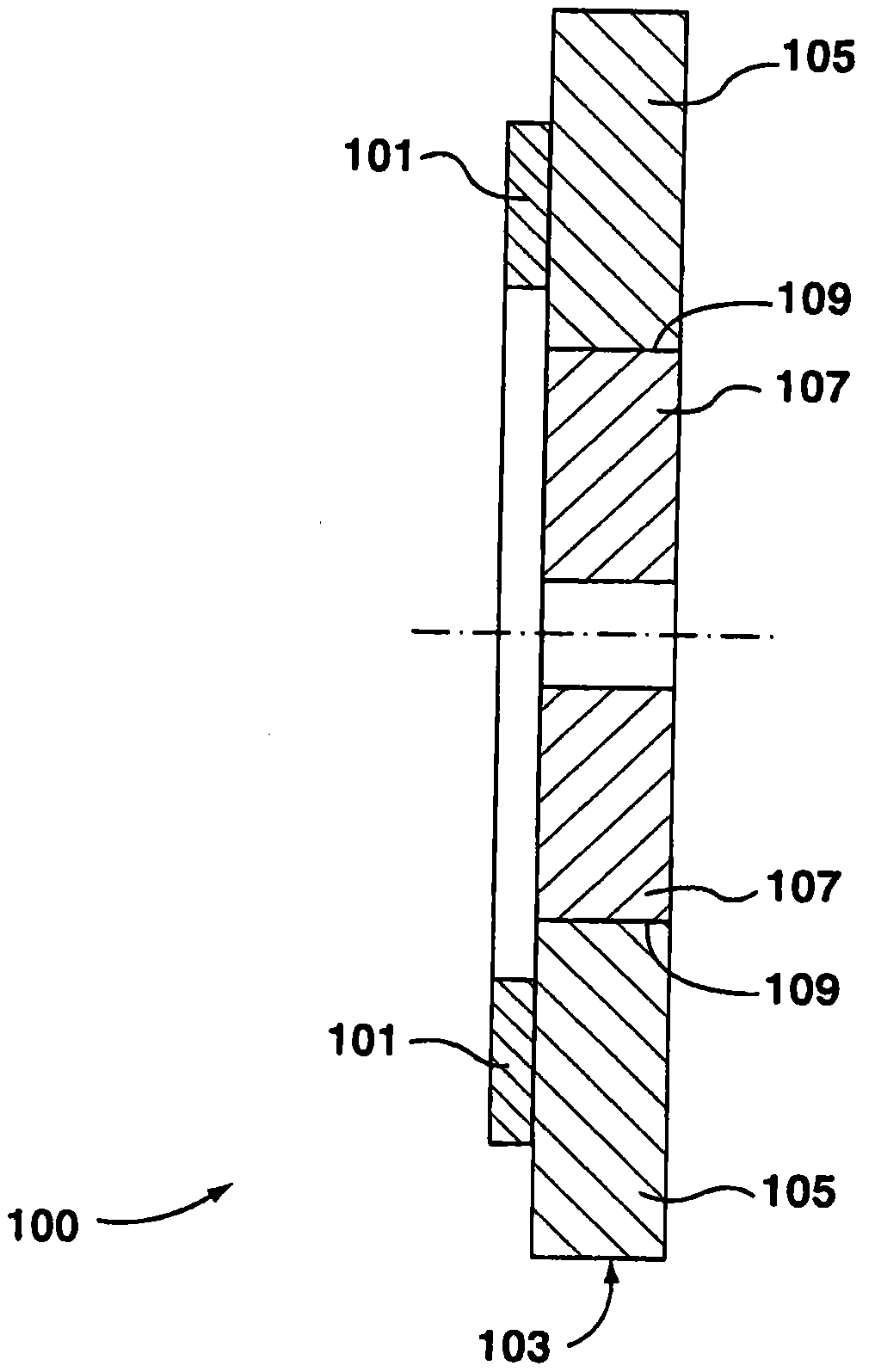

[0039] see next figure 2 , which shows a cross-sectional view of a device 100 similar to that of FIG. , the first material 105 includes a first coefficient of thermal expansion (CTE), and the second material 107 is bonded to the first material 105 at an interface 109 between the second material and the first material, the second material 107 includes With a second CTE low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com