Quantitative evaluation method for laser cladding remanufacturing product heat injury feature

A quantitative evaluation and laser cladding technology, applied in the direction of testing material hardness, etc., can solve the problems of single evaluation index of thermal damage characteristics, quantitative evaluation of undiscovered thermal damage degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

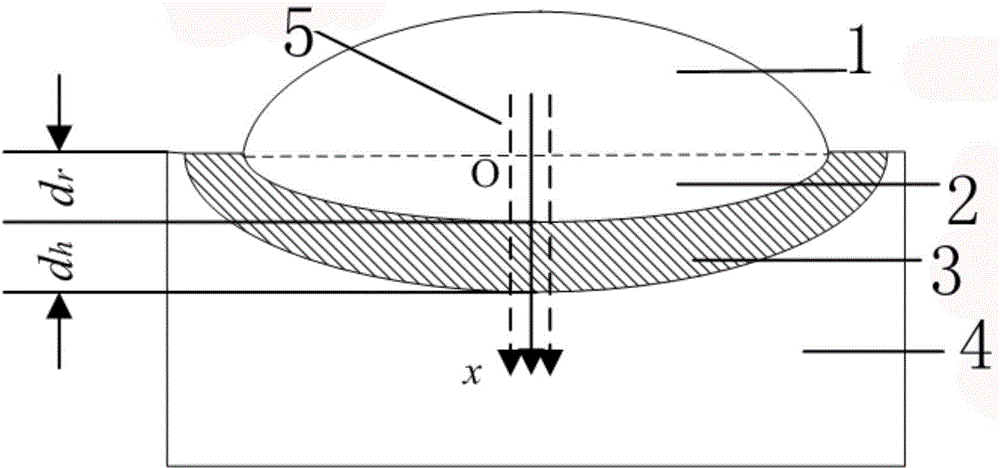

[0035] The specific implementation manners of the present invention and related mathematical processing methods will be described in detail below in conjunction with the accompanying drawings.

[0036] In order to overcome the problems of single thermal damage evaluation factors and poor quantification effect in the existing method for laser cladding remanufacturing process, the present invention discloses a quantitative evaluation method for damage characteristics of laser cladding remanufacturing products. This method is aimed at the evaluation of the damage characteristics of laser cladding remanufactured products. The same material and process as the product are used to prepare samples by single-pass cladding on the regular surface, and the damage characteristics of the samples are studied under test and simulation conditions. The direct failure of the product is measured.

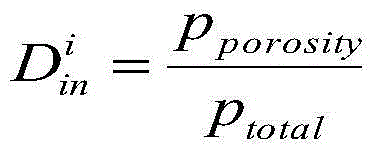

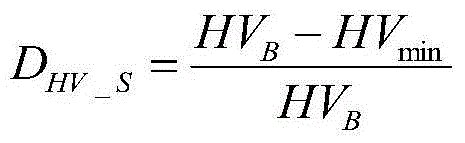

[0037] According to the present invention, the evaluation of thermal damage in the laser cladding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com