Design method for handle of cooker used for manufacturing fried bread sticks

A design method and handle technology, which can be applied to utensils for frying things in oil, household utensils, kitchen utensils, etc., can solve the problems of low yield of round pots and increase labor costs, and achieve friendliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

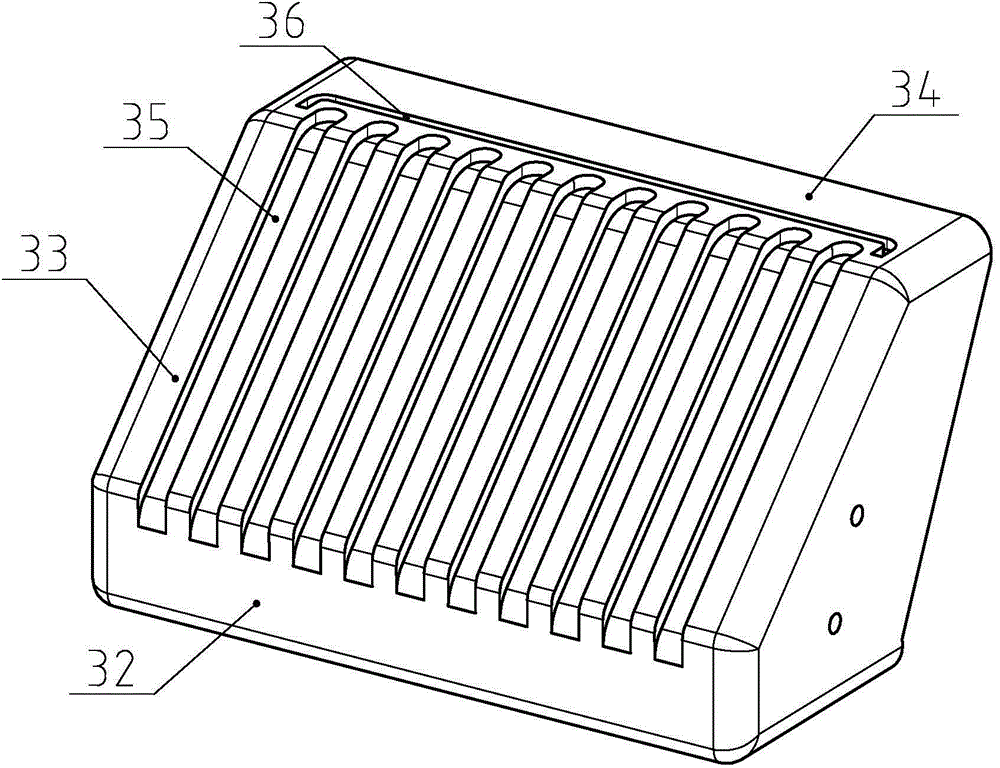

[0028] Such as figure 1 As shown, it is a perspective view of the handle 3, the second supporting surface 33 is provided with 11 first grooves 35 at equal intervals, the first grooves 35 extend to the first supporting surface 32 and the mounting surface 34, and the mounting surface 34 is provided with The second groove 36 of the partial cover 4 is received.

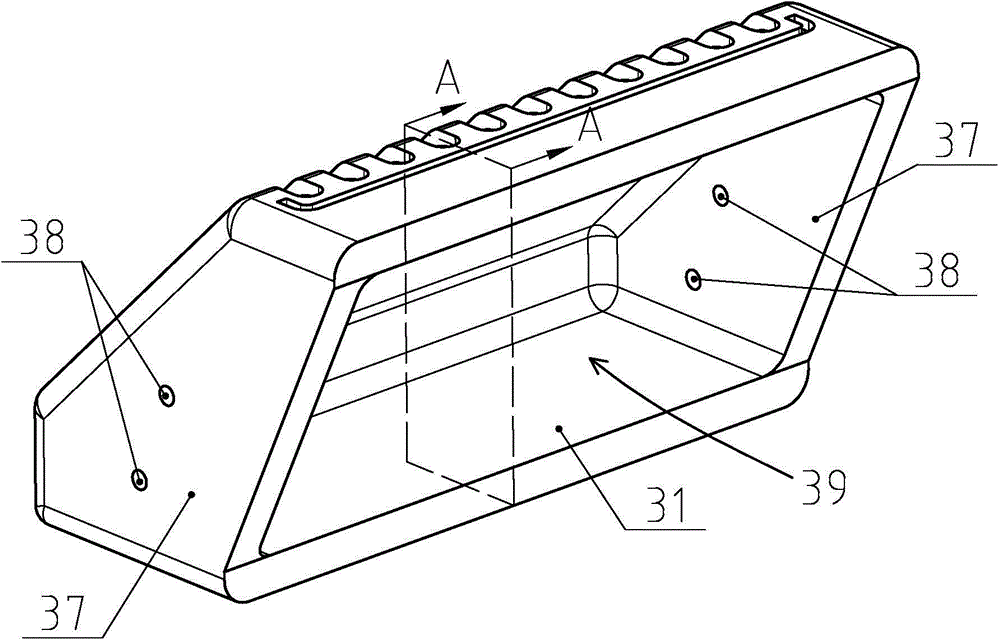

[0029] Such as figure 2 As shown, it is a perspective view of the handle 3. The handle 3 is composed of a fixed surface 31, a first support surface 32, a second support surface 33, an installation surface 34 and two side surfaces 37. The fixed surface 31, the first support surface 32, the second The supporting surface 33, the mounting surface 34 and the two side surfaces 37 encircle a third receiving chamber 39 opening to the right for receiving hands, and the two side surfaces 37 of the handle 3 are respectively provided with two third chambers for assembling fastening bolts. Through hole 38 .

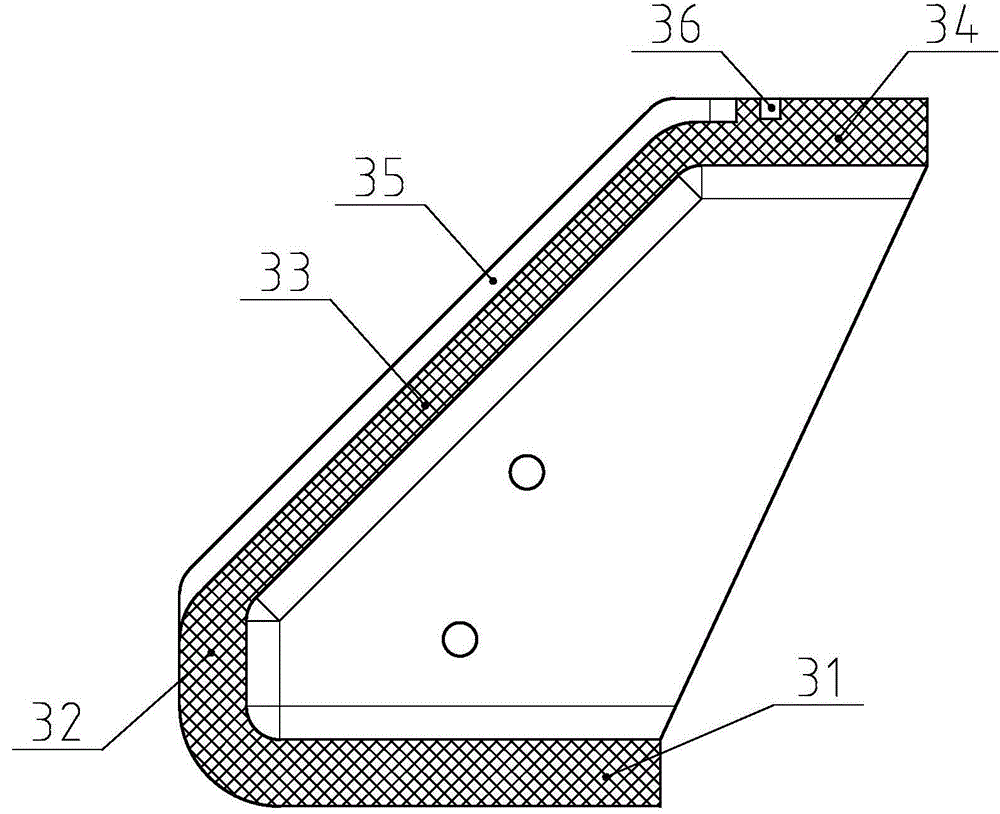

[0030] Such as imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com