Static mixing device of trace moulding and extracting material

A static mixing device and trace technology, applied in fluid mixer, mixer, dissolving and other directions, can solve the problems of long time, difficult to effectively control the silicone rubber molding time, complicated operation, etc., to achieve rapid mixing, improve efficiency and trace the extraction rate, the effect of improving the dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

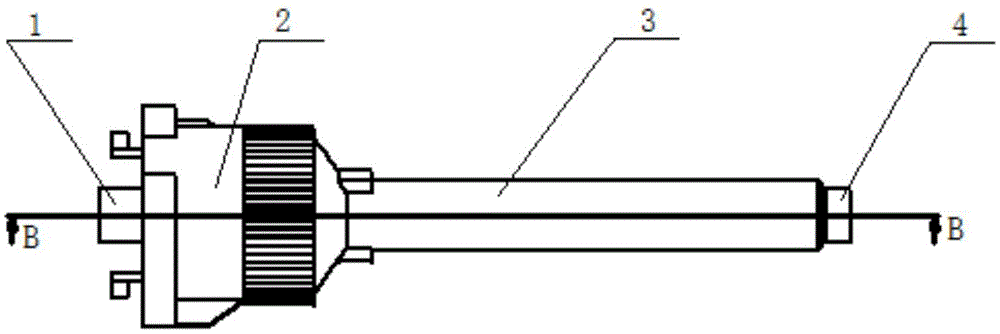

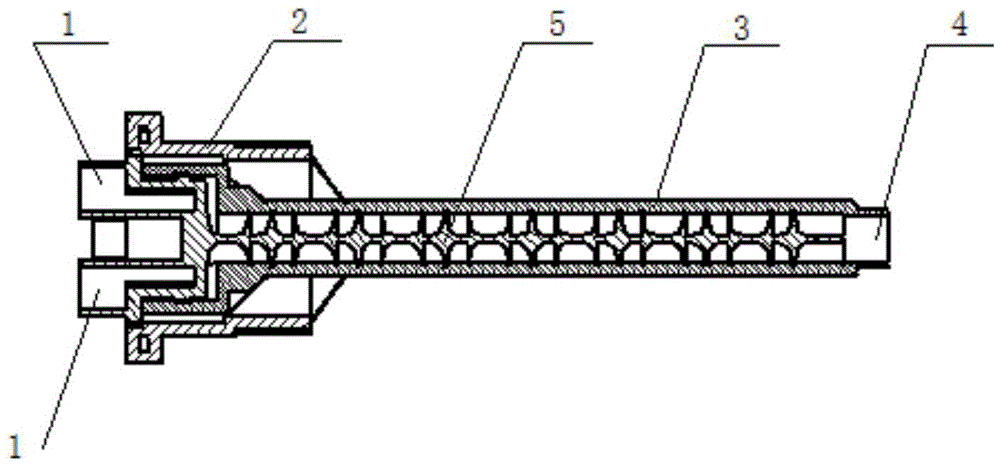

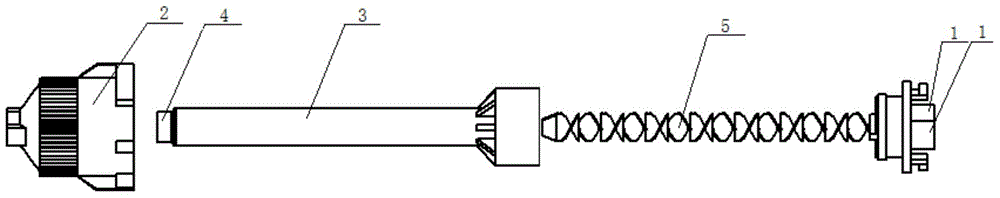

[0022] A static mixing device, comprising a mixing chamber 3, a mixing screw 5 and a connecting sleeve 2, the mixing chamber 3 and the mixing screw 5 are connected by the connecting sleeve 2.

[0023] One end of the mixing screw 5 is provided with a feed port 1 and a first joint; one end of the mixing chamber 3 is provided with a discharge port 4, and the other end is provided with a second joint; the mixing screw 5 The shape of the first joint part of the mixing chamber 3 and the shape of the second joint part of the mixing chamber 3 match the shape of the connecting sleeve 2; the cross section of the mixing chamber 3, the mixing screw 5 and the connecting sleeve 2 is circular , square or rectangular; preferably, circular; the connection mode of the first joint part of the mixing screw 5, the second joint part of the mixing chamber 3 and the connecting sleeve 2 is a non-detachable connection, specifically a ring clip Groove connection; the outer diameter of the mixing screw 5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap