Reagent continuous quantitative injection device

A quantitative injection and reagent technology, applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., can solve the problems of low injection efficiency of titrators, and achieve the effect of improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

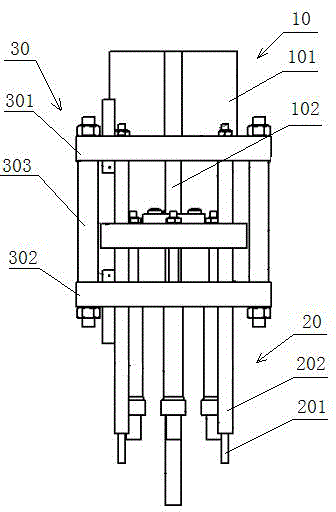

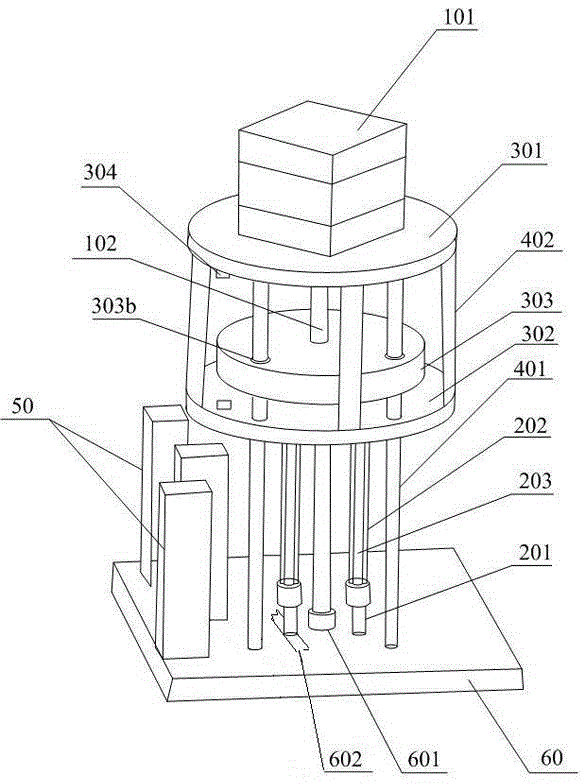

[0017] Embodiment 1, this embodiment proposes a continuous quantitative injection device for reagents, such as figure 1 As shown, it includes a power mechanism 10, at least one syringe 20, and a support connection mechanism 30. The support connection mechanism 30 includes an upper fixing plate 301, a lower fixing plate 302, and an adapter plate 303. The power mechanism 10 includes a motor 101 and the power output shaft 102, the syringe 20 includes a needle 201, a syringe 202, a piston rod 203, and a piston 204 fixed at the end of the piston rod 203, and the upper fixing plate 301 is fixed on the micro Above the flow control chip 60, the lower fixing plate 302 is located below the upper fixing plate 301, and is fixedly connected to the upper fixing plate 301 through a connecting rod 402, and the adapter plate 303 is located on the upper fixing plate 301 and the lower fixing plate 302, and the adapter plate 303 is provided with a guide hole 303b for allowing the support rod 401 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com