Large-section foamed plastic product extruding machine head

A foaming plastic, extrusion head technology, applied in the coating and other directions, can solve the problems of not meeting technical requirements, not meeting process requirements, and unstable product shape when shrinking products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

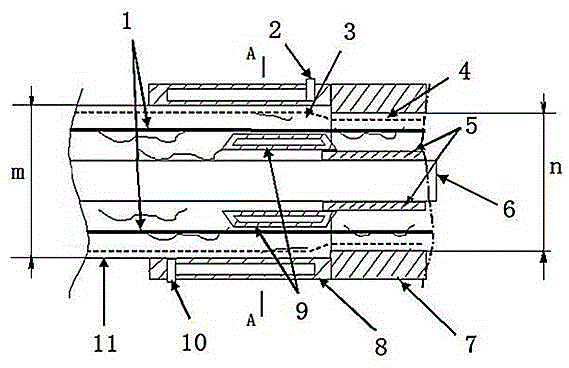

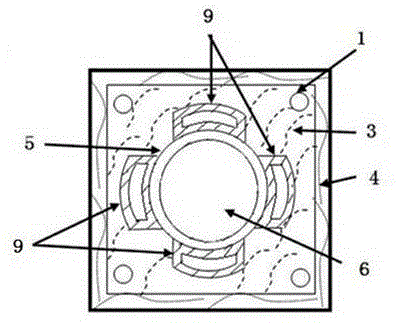

[0013] See figure 1 , 2 , the specific structure is as follows: the extruder head 7 of the prior art is adopted, and the guide sleeve 5 is set in the head 7; the technical points are: the rear end of the square head 7 is provided with a square shaped sleeve 8 with a cross section, The shaping sleeve 8 is provided with a cooling water ring chamber, and the cooling water ring chamber is provided with a cooling water inlet 10 and a cooling water outlet 2; the inner single side m of the square shaping sleeve 8 is larger than the inner single side n size of the square extrusion port of the machine head 7, and the difference is 0.8-1.6mm; a plurality of flow blocking devices 9 arranged intermittently in the same circumference are arranged at the rear of the guide sleeve 5, and the inner surface of the front end of each flow blocking device 9 is fastened to the rear outer surface of the guide sleeve 5 Above, that is, the location of the choke device is designed outside the machine h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com