Anti-counterfeiting thermoprinting foil and preparation method thereof

A technology of hot stamping foil and color printing, which is applied in the field of anti-counterfeiting hot stamping foil and its preparation, can solve the problems of reducing anti-counterfeiting strength, achieve the effects of improving anti-counterfeiting strength, enhancing anti-counterfeiting exclusivity, and facilitating secondary production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 2 million customer orders

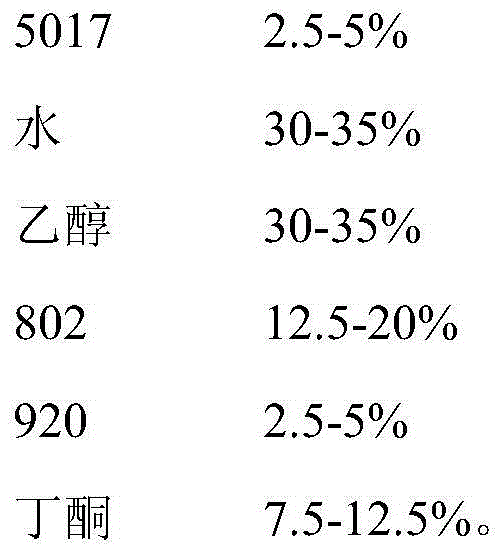

[0039] (1) Coating release layer: select 16μm double-sided non-corona PET, use a coater to coat the release layer, and the drying method is thermal drying. The release layer is made of the following raw materials by weight percentage:

[0040]

[0041] (2) Holographic layer: Using a soft pressing process, the holographic information is copied to the release layer.

[0042] (3) Digital production: use the principle of chromosome base pairing to different two sets of data, pair them to form two interconnected data chains, so that they have a one-to-one correspondence.

[0043] (4) The first digital layer: use a coding machine to print the digital on one of the data chains to the specified position.

[0044] (5) Aluminized layer: aluminum plating is performed by vacuum aluminum plating; the square resistance of the aluminum plating layer is 0.6.

[0045] (6) Printing color: Use a printing press to print white in the specified area.

[0046] (7) The second ...

Embodiment 2

[0050] 3 million customer orders

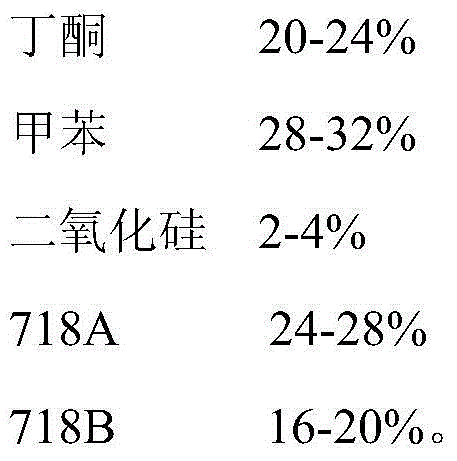

[0051] (1) Coating release layer: select 20μm double-sided non-corona PET, use a coater to coat the release layer, and the drying method is thermal drying. The release layer is made of the following raw materials by weight percentage:

[0052]

[0053]

[0054] (2) Holographic layer: Using a soft pressing process, the holographic information is copied to the release layer.

[0055] (3) Digital production: Divide the source digital into two using the principle of chromosome base pairing, pair them to form two interconnected data chains, so that they have a one-to-one correspondence.

[0056] (4) The first digital layer: use a coding machine to print the digital on one of the data chains to the specified position.

[0057] (5) Aluminized layer: Aluminized by vacuum aluminizing method; the square resistance of the aluminized layer is 0.8.

[0058] (6) Printing color: Use a printing press to print white in the specified area.

[0059] (7) The second digital...

Embodiment 3

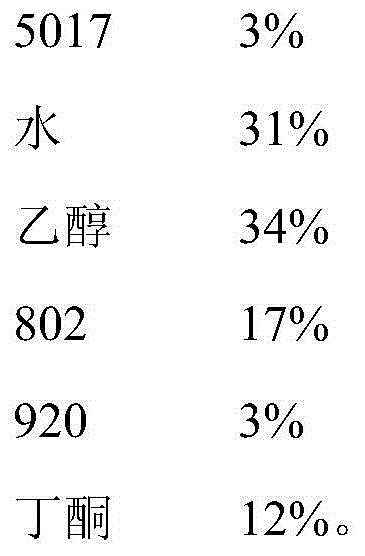

[0063] 3.5 million customer orders

[0064] (1) Coating release layer: select 30μm double-sided non-corona PET, use a coating machine to coat the release layer, and the drying method is thermal drying. The release layer is made of the following raw materials by weight percentage:

[0065]

[0066] (2) Holographic layer: Using a soft pressing process, the holographic information is copied to the release layer.

[0067] (3) Digital production: Use the principle of chromosome base pairing to match different two sets of data to form two interconnected data chains, so that they have a one-to-one correspondence.

[0068] (4) The first digital layer: use a coding machine to print the digital on one of the data chains to the specified position.

[0069] (5) Aluminized layer: Aluminium plating is carried out by a vacuum aluminum plating method; the square resistance of the aluminum plating layer is 1.0.

[0070] (6) Printing color: Use a printing press to print white in the specified area.

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com