A laminated glass initial pressing production line

A technology of laminated glass and production line, applied in glass/slag layered products, layered products, chemical instruments and methods, etc., can solve problems such as easy false alarms and vacuum leakage, and achieve the effect of reducing false alarms and ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

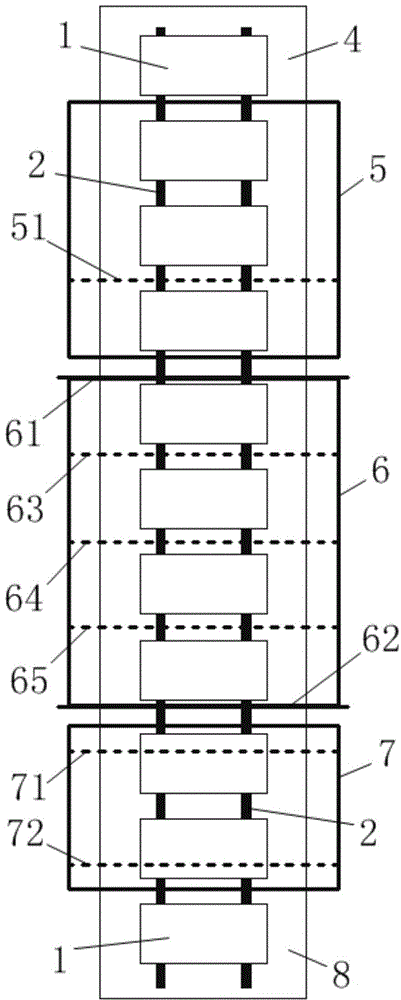

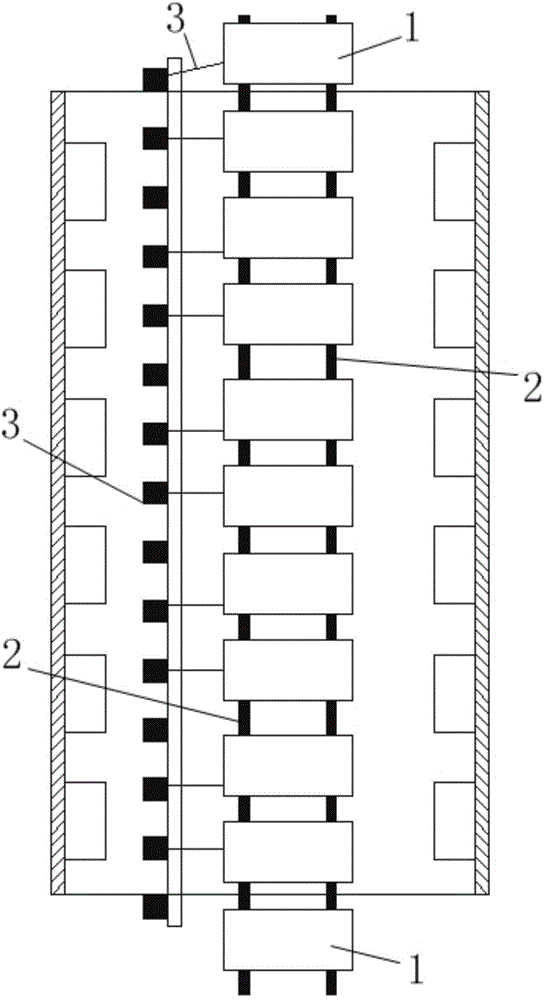

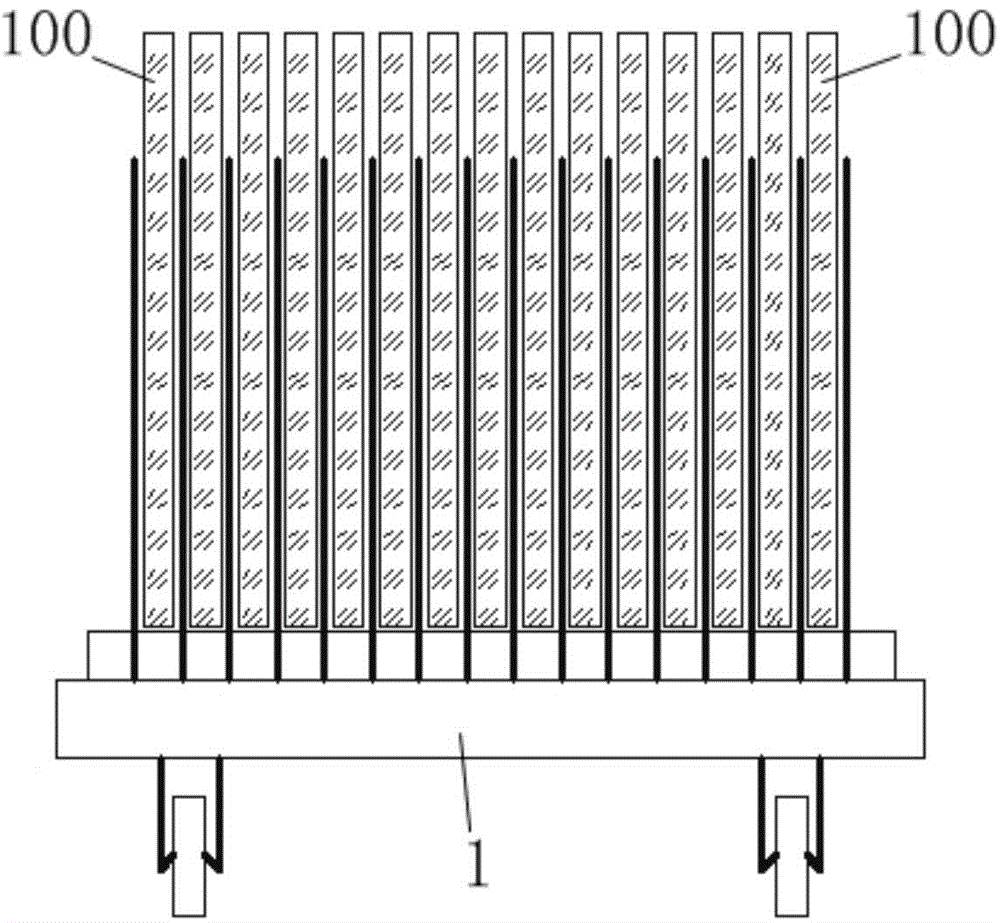

[0025] Such as figure 1 and figure 2 As shown, a laminated glass initial pressure production line according to the present invention is used for initial pressure and vacuum treatment of laminated glass. The upper area 4, the cold extraction area 5, the constant temperature area 6, the cooling area 7 and the lower area 8 are set in sequence; among them, the loading trolley 1 is used to place multiple pieces of laminated glass, and the loading trolley 1 is fixedly placed on the transmission device 2, and the transmission The device 2 can drive the loading trolley 1 to move sequentially between the upper area 4, the cold extraction area 5, the constant temperature area 6, the cooling area 7 and the lower area 8, and the air extraction device 3 is used to extract at least 70% of the air in the laminated glass , the upper area 4 is used to fix the loading trolley with multiple pieces of laminated glass on the transmission device 2 and communicate each piece of laminated glass wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com