A connection device and connection method for a pile leg and a pile shoe

A connection device and spud shoe technology, which is applied in sheet pile walls, water conservancy projects, artificial islands, etc., can solve the problems affecting the connection performance of pile legs and spud shoes, the stability of unstable connection platform, and the influence of platform stability, etc., to achieve Reduce pile pulling force, facilitate stable work, and reduce pile pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

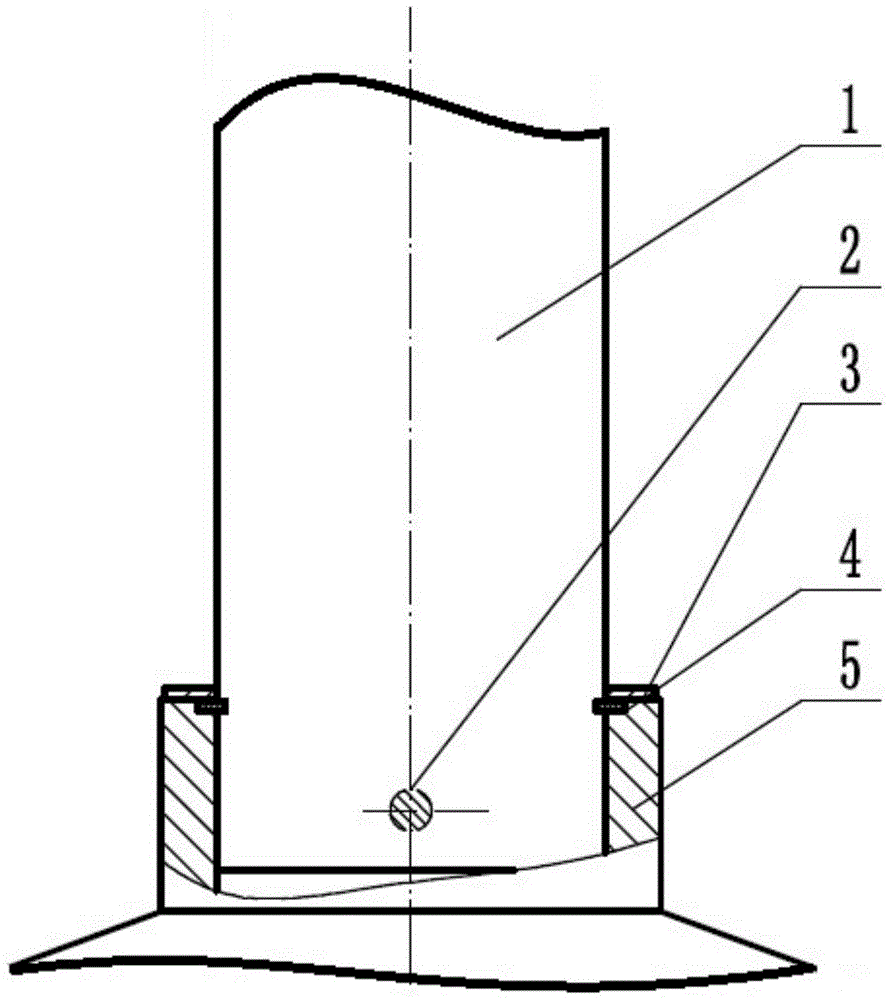

[0016] Example as figure 1 As shown, a connection device between a spud leg and a spud can, the device includes a spud leg 1 and a spud can, the spud can includes a spud can joint and a spud can joint hole, and the spud leg 1 is inserted into the spud can joint In the hole 5, the spud leg 1 and the spud shoe joint respectively include at least one pin hole, and at least one positioning pin 2 is correspondingly inserted into the pin hole. The spud shoe joint also includes a joint groove, and the joint groove is provided with a locking ring 4 and a cover plate 3, and the cover plate 3 abuts the locking ring 4 and is fixed to the locking ring 4 by bolts. The spud legs and the spud boots are connected and fixed through three parts. The first part is to insert the spud legs into the spud boots and fix the spud legs horizontally; the second part is to insert the positioning pins into the pin holes of the spud boots and spud legs, The pile leg is positioned axially; the third part i...

Embodiment 2

[0017] Example two such as figure 1 As shown, a method for connecting spud legs and spud cans: insert the spud legs 1 into the spud can joint holes 5 to reach the matching length, insert the positioning pins 2 into the pin holes of the spud legs 1 and the spud can joints respectively Press the locking ring 4 into the joint groove of the spud shoe joint, then place the cover plate 3 on the locking ring 4 and fix it with bolts; connect the spud legs 1 with the cover The plate 3 is welded, and the cover plate 3 and the spud shoe are welded. The spud legs and the spud boots are connected and fixed through three parts. The first part is to insert the spud legs into the spud boots and fix the spud legs horizontally; the second part is to insert the positioning pins into the pin holes of the spud boots and spud legs, Axial positioning of the pile leg; the third part is the horizontal fixation of the locking ring and the cover plate, the locking ring clamps the pile leg in the spud s...

Embodiment 3

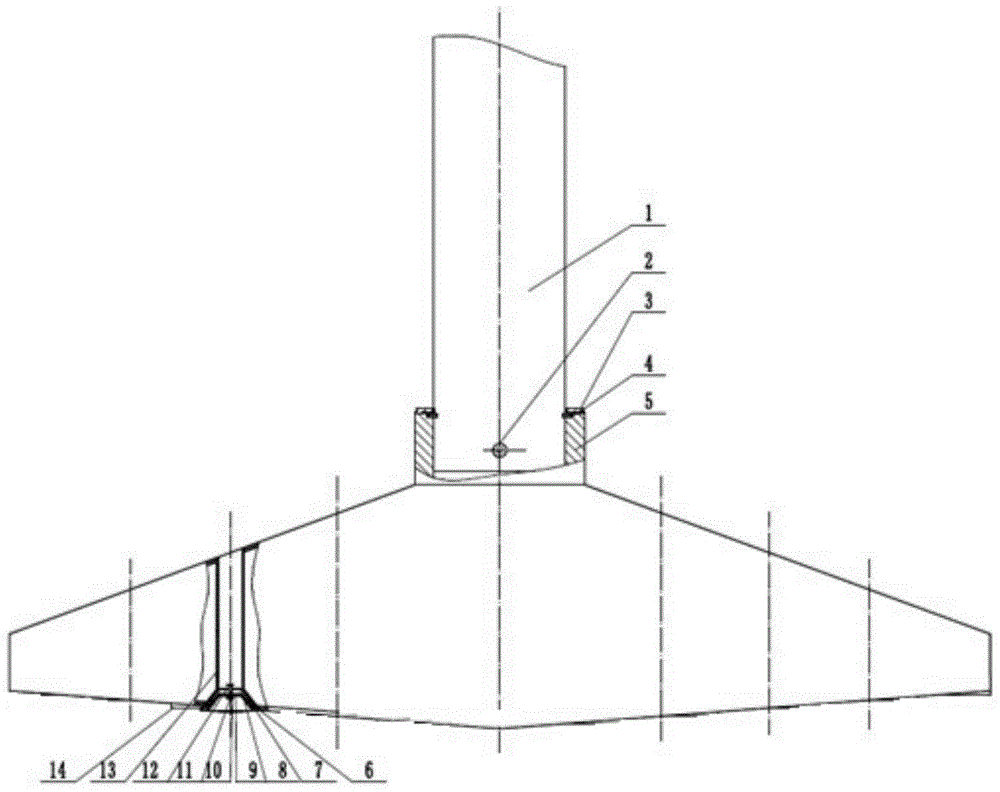

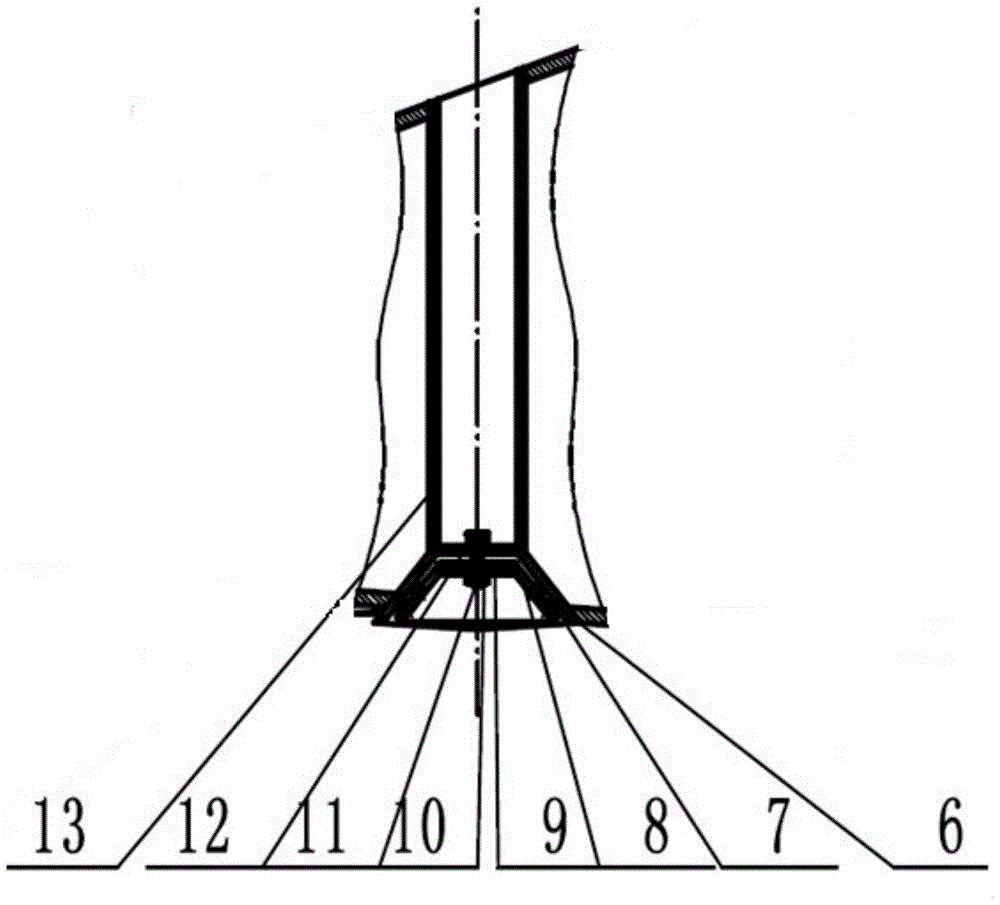

[0018] Embodiment three such as figure 2 As shown, a connection device between a spud leg and a spud can, the device includes a spud leg 1 and a spud can, the spud can includes a spud can joint and a spud can joint hole, and the spud leg 1 is inserted into the spud can joint In the hole 5, the spud leg 1 and the spud shoe joint respectively include at least one pin hole, and at least one positioning pin 2 is correspondingly inserted into the pin hole. The spud shoe joint also includes a joint groove, and the joint groove is provided with a locking ring 4 and a cover plate 3, and the cover plate 3 abuts the locking ring 4 and is fixed to the locking ring 4 by bolts. The spud legs and the spud boots are connected and fixed through three parts. The first part is to insert the spud legs into the spud boots and fix the spud legs horizontally; the second part is to insert the positioning pins into the pin holes of the spud boots and spud legs, The pile leg is positioned axially; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com