Water pump shaft structure

A pump shaft and water pump technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of weak pump shaft tensile strength, small positioning plane, poor pump shaft strength, etc., to shorten the processing time and process. , Ensure parallelism and strength, increase the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

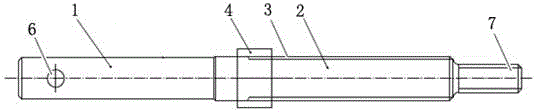

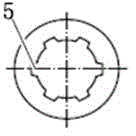

[0014] Combine below figure 1 and figure 2 Specific description embodiment:

[0015] The pump shaft structure of the water pump, the pump shaft structure of the water pump includes the smooth end part 1 and the spline tooth end part 2 formed at one time by extrusion and stretching process, and the outer wall at the junction of the smooth end part 1 and the spline tooth end part 2 A number of external teeth 3 are arranged on the upper part; an impeller positioning sleeve 4 is provided at the junction of the smooth end part 1 and the spline tooth end part 3, and the inner wall of the impeller positioning sleeve 4 is provided with a center positioning one-time extrusion forming Inner tooth 5, inner tooth 5 matches with outer tooth 3. The light end part 1 is provided with a pin hole 6 for adjusting the installation size of the impeller in the pump. The spline tooth end portion 2 is provided with a screw thread 7 for fixing the axial position of the impeller.

[0016] When usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com